Showing 1–12 of 69 results

- SKU:LLS-EXPLB-75-5-C1D2 | Web ID:2684Availability: 77 In Stock Ships 3-5 Days

- Watts: 75

- Lumens: 10500

- Lumens/Watt: 140

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 10kV

- Operating Temp: -40°F to 149°F

- Rated Life: 150,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Mount (Opt): Surface | Wall

- Cord Length: No Cord

- Weight: 13 lbs

Starting At$485.00 - SKU:LLS-EXPLB-100-5-C1D2 | Web ID:2310Availability: 15 In Stock Ships 2-3 Days

- Watts: 100

- Lumens: 14000

- Lumens/Watt: 140

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 10kV

- Operating Temp: -40°F to 149°F

- Rated Life: 150,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Mount (Opt): Surface | Wall

- Cord Length: No Cord

- Weight: 13 lbs

Starting At$555.00 - SKU:LLS-EXPLB-150-5-C1D2 | Web ID:2311Availability: 178 In Stock Ships 2-3 Days

- Watts: 150

- Lumens: 21000

- Lumens/Watt: 140

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 10kV

- Operating Temp: -40°F to 149°F

- Rated Life: 150,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Mount (Opt): Surface | Wall

- Dimensions: 9.68 in H x 14.96 in D

- Cord Length: No Cord

- Weight: 20 lbs

Starting At$595.00 - SKU:LLS-EXPLB-200-5-C1D2 | Web ID:2682Availability: 67 In Stock Ships 3-5 Days

- Watts: 200

- Lumens: 28000

- Lumens/Watt: 140

- Replaces: 1000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 10kV

- Operating Temp: -40°F to 149°F

- Rated Life: 150,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Mount (Opt): Surface | Wall

- Dimensions: 9.7 X 15 in

- Cord Length: No Cord

- Weight: 20 lbs

Starting At$635.00 - SKU:MLLG-E-LED-EXPLB-40-50-[V]-C1D2 | Web ID:1606100V-277V:277V-480V:Built to Order 6 Weeks

- Watts: 40

- Lumens: 5600

- Lumens/Watt: 140

- Replaces: 175 | 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 140°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 7.09 x 9.09 in

- Weight: 8 lbs

Contact Us For Pricingx - SKU:MLLG-E-LED-EXPLB-60-50-[V]-C1D2 | Web ID:1609100V-277V:38 In StockShips 3-5 Days277V-480V:Built to Order 6 Weeks

- Watts: 60

- Lumens: 8400

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 140°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 7.09 x 9.09 in

- Weight: 8 lbs

Starting At$528.30 - SKU:MLLG-E-LED-EXPLB-80-50-[V]-C1D2 | Web ID:1644100V-277V:938 In StockShips 3-5 Days277V-480V:Built to Order 6 Weeks

- Watts: 80

- Lumens: 11200

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 140°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 10.63 X 10.47 in

- Weight: 9.7 lbs

Starting At$547.17 - SKU:MLLG-E-LED-EXPLB-80-50-C1D2-HT | Web ID:2302Built to Order 8 Weeks

- Watts: 80

- Lumens: 8000

- Lumens/Watt: 100

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 120V

- Surge Protection: 10kV

- Operating Temp: -40°F to 176°F

- Rated Life: 50,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 9.1 X 8.7 in

- Weight: 15 lbs

Starting At$786.20 - SKU:MLLG-E-LED-EXPLB-100-50-C1D2-HT | Web ID:2303Built to Order 8 Weeks

- Watts: 100

- Lumens: 10000

- Lumens/Watt: 100

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 120V

- Surge Protection: 10kV

- Operating Temp: -40°F to 176°F

- Rated Life: 50,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 14 in D X 11.3 in H

- Weight: 26 lbs

Starting At$856.00 - SKU:MLLG-E-LED-EXPLB-150-50-[V]-C1D2 | Web ID:1612100V-277V:260 In StockShips 3-5 Days277V-480V:36 In StockShips 3-5 Days

- Watts: 150

- Lumens: 21000

- Lumens/Watt: 140

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 140°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 14.56 X 11.4 in

- Weight: 18.1 lbs

Starting At$650.94 - SKU:MLLG-E-LED-EXPLB-150-50-C1D2-HT | Web ID:2304Built to Order 8 Weeks

- Watts: 150

- Lumens: 15000

- Lumens/Watt: 100

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 120V

- Surge Protection: 10kV

- Operating Temp: -40°F to 176°F

- Rated Life: 50,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 14 X 11.3 in

- Weight: 28 lbs

Starting At$1,089.70 - SKU:MLLG-E-LED-EXPLB-200-50-[V]-C1D2 | Web ID:1643100V-277V:367 In StockShips 3-5 Days277V-480V:Built to Order 6 Weeks

- Watts: 200

- Lumens: 28000

- Lumens/Watt: 140

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 140°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 14.56 X 11.4 in

- Weight: 18.1 lbs

Starting At$703.70

What is Class I Division 2 LED Lighting for Hazardous Locations?

LED Lighting Supply specifies and supplies Class I, Division 2 LED lighting fixtures for industrial environments where flammable gases or vapors are not normally present, but may occur under abnormal operating conditions such as equipment failure, container leakage, or system malfunction. With more than 15 years of experience in hazardous location and explosion-proof lighting, our product specialists work directly with engineers, safety managers, and contractors to ensure fixture selection aligns with code requirements, inspection expectations, and real-world operating conditions.

Class I, Division 2 locations are defined by the National Electrical Code (NEC), NFPA 70, and are regulated in conjunction with OSHA hazardous location guidance. In these environments, luminaires must be designed to prevent ignition during abnormal events while maintaining safe operation during normal conditions. Improper fixture selection can result in failed inspections, insurance conflicts, and elevated ignition risk, making compliance-driven product selection critical.

All Class I, Division 2 LED luminaires supplied by LED Lighting Supply are certified by nationally recognized testing laboratories (NRTLs) and evaluated in accordance with applicable NEC, UL, and CSA standards. Fixtures are selected based on the specific gas or vapor group classification (Groups A, B, C, or D) and are engineered to meet the ignition prevention requirements associated with each material's combustion characteristics.

Important Safety and Compliance Notice: Information provided regarding Class I, Division 2 hazardous location lighting is intended for general guidance only and does not replace applicable codes, standards, or site-specific engineering judgment. Final equipment selection must be verified by a qualified professional and approved by the authority having jurisdiction (AHJ) in accordance with the National Electrical Code (NFPA 70), OSHA regulations, and all applicable local requirements.

Defining Class 1 Div 2 Hazardous Area Classifications

Group A encompasses acetylene, presenting the greatest danger due to extremely low ignition energy requirements. Group B covers hydrogen and similar gases with dangerous flame speeds. Group C includes ethylene, propane, and cyclopropane, commonly found in chemical processing facilities. Group D handles propane, butane, methane, gasoline, and benzene, representing the most frequently encountered flammable vapors.

Division classification depends on hazardous atmosphere exposure frequency. Division 1 areas have a continuous or frequent presence of ignitable concentrations requiring constant protection. Division 2 locations experience hazardous conditions only during abnormal circumstances, including equipment maintenance, system breakdowns, or accidental releases.

The National Fire Protection Association's NFPA 70, also known as the National Electrical Code, provides comprehensive requirements for electrical installations in hazardous locations. NFPA 70 Article 500 series defines the specific installation requirements and equipment standards that ensure electrical systems remain safe in environments where flammable gases and vapors may be present.

We engineer solutions that address Division 2 requirements for storage areas, loading docks, and equipment rooms where proper ventilation normally prevents vapor accumulation. Division 1 fixtures become necessary in paint mixing rooms, tank interiors, and process vessels where hazardous atmospheres exist during regular operations.

Case Study: Conversion of existing lighting to LED Lighting Supply Class 1 Division 2 Fixtures in Holbrook, AZ

|

After: 200 Watt Square Explosion Proof LED Light | 28000 Lumens |

After: 200 Watt Square Explosion Proof LED Light | 28000 Lumens |

|

|

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

Explosion Proof Lighting Installation Plan Metrics

- Mounting height: 20 ft

- Fixture Used: MLLG-E-LED-EXPLA-200-50-[V]-C1D2: 200 Watt Square Explosion Proof LED Light | 28000 Lumens | Class 1 Div 2 | Class 2 Div 2 | 5000K | 100V-277V or 277V-480V

- FC achieved: 62.80 FC average

- Uniformity (Avg/Min): 1.85

Use When / Don't Use When

Use Class I Division 2 LED Fixtures When

- Hazardous atmospheres occur only during abnormal conditions - Equipment failure, container leakage, or system malfunction scenarios

- Normal operations properly contain flammable materials - Storage areas, loading docks, equipment rooms with adequate ventilation

- You need energy savings without Division 1 over-specification - 65% energy reduction compared to metal halide, while meeting safety requirements

- Maintenance access is restricted - 50,000+ hour operation eliminates frequent fixture service in classified areas

- Instant emergency illumination is critical - 100% brightness instantly, without metal halide warm-up delays

Don't Use Class I Division 2 LED Fixtures When

- Hazardous atmospheres exist during normal operations - Paint mixing rooms, tank interiors, process vessels require Division 1 protection

- You're in a Class II (combustible dust) environment - Grain facilities need dust-ignition-proof equipment, not gas/vapor ratings

- Temperature ratings don't match your application - Fixture T-rating must stay below the ignition temperature of specific materials present

- Installation lacks a proper explosion-proof conduit system - Standard fittings and missing seals create dangerous ignition paths

- Fixtures aren't certified for your specific hazardous group - Group A (acetylene) requires different protection than Group D (gasoline/propane)

What We Verify Before You Order

We confirm

- Specific hazardous material group classification (A, B, C, or D)

- Required temperature rating for your materials

- Ambient operating conditions and corrosion exposure

- Mounting requirements and maintenance accessibility

- Electrical system voltage and dimming needs

If we provide a lighting plan, you will get

- Detailed fixture placement optimized for safety and maintenance access

- Exact energy savings calculations with ROI projections

- Specification sheets showing NEC and NFPA compliance documentation

Note: Guidance is general planning information. Final selection should be validated with a photometric plan and confirmed by a licensed professional when required for code- or safety-critical areas.

Quick Selection Guide

- Confirm hazardous material group (A, B, C, or D) - Group A (acetylene) requires most restrictive fixtures; Group D (propane, gasoline, methane) is most common

- Verify Division 2 classification applies - Use when hazardous atmospheres occur only during abnormal conditions (equipment failure, leaks, maintenance)

- Check temperature rating requirements - Match fixture T-rating to maximum surface temperature limits for your specific materials

- Select UL844-certified fixtures only - Require UL Listed or ETL Listed with specific Class I Division 2 markings

- Plan conduit and seal requirements - All connections need explosion-proof fittings and seals within 18 inches of enclosures

- Consider maintenance accessibility - Position fixtures away from potential leak points to avoid hot work permits during service

Tip: Don't assume all Group D fixtures work for every Group D material - some chemicals require special corrosion protection even within the same classification.

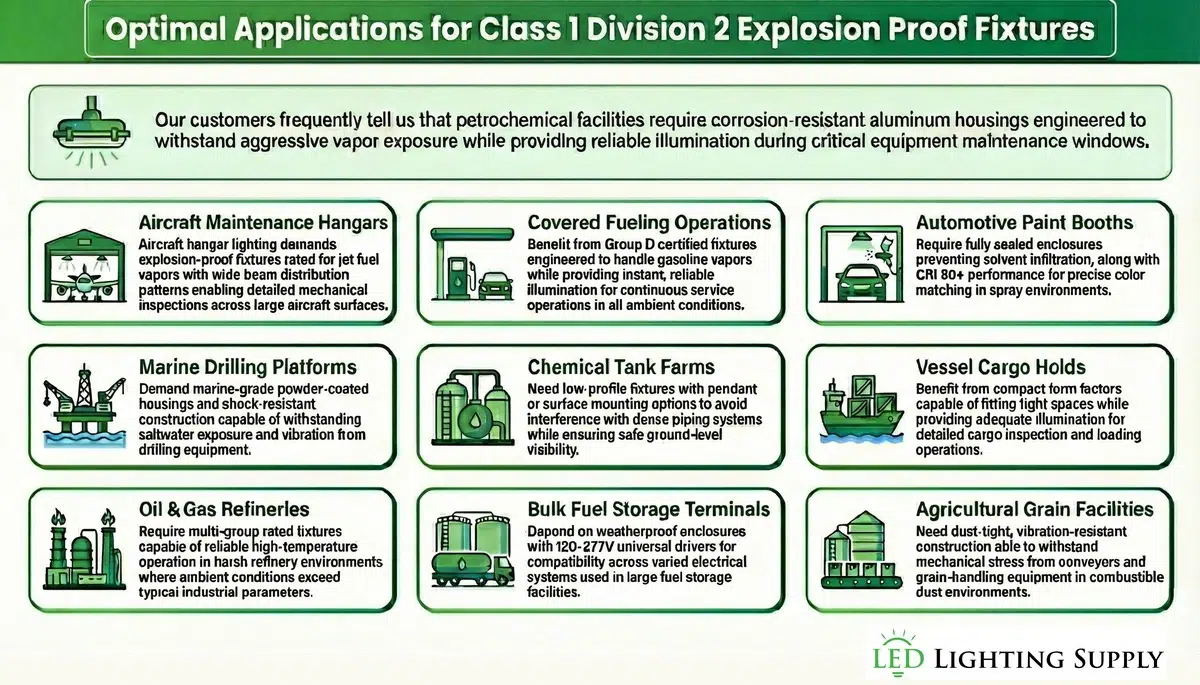

Optimal Applications for Explosion Proof Fixtures

- Aircraft Maintenance Hangars - LED aircraft hangar lights can be explosion-proof fixtures rated for jet fuel vapors with wide beam distribution patterns enabling detailed mechanical inspections across large aircraft surfaces.

- Covered Fueling Operations - Benefits from Group D certified fixtures engineered to handle gasoline vapors while providing instant, reliable illumination for continuous service operations in all ambient conditions.

- Automotive Paint Booths - Require fully sealed enclosures preventing solvent infiltration, along with CRI 80+ performance for precise color matching in spray environments.

- Marine Drilling Platforms - Demand marine-grade powder-coated housings and shock-resistant construction capable of withstanding saltwater exposure and vibration from drilling equipment.

- Chemical Tank Farms - Need low-profile fixtures with pendant or surface mounting options to avoid interference with dense piping systems while ensuring safe ground-level visibility.

- Vessel Cargo Holds - Benefit from compact form factors capable of fitting tight spaces while providing adequate illumination for detailed cargo inspection and loading operations.

- Oil & Gas Refineries - Require multi-group rated fixtures capable of reliable high-temperature operation in harsh refinery environments where ambient conditions exceed typical industrial parameters.

- Bulk Fuel Storage Terminals - Depend on weatherproof enclosures with 120-277V universal drivers for compatibility across varied electrical systems used in large fuel storage facilities.

- Agricultural Grain Facilities - Need dust-tight, vibration-resistant construction able to withstand mechanical stress from conveyors and grain-handling equipment in combustible dust environments.

Proven Benefits of Explosion Proof LED Solutions

- Extended Operational Reliability - Fixtures provide 50,000+ hour operation without driver replacement, eliminating hazardous maintenance work in classified areas that require hot-work permits and continuous gas monitoring.

- Immediate Energy Cost Reduction - Reduces electricity consumption by 65% compared to metal halide or fluorescent systems, model dependent. Lower power draw produces less heat, crucial for maintaining safe temperatures in enclosed hazardous environments.

- Advanced Heat Management Technology - LED systems convert 95% of input power into light rather than waste heat when properly specified. Cooler operating temperatures reduce ignition risk and lower HVAC load in climate-controlled chemical storage facilities.

- Enhanced Safety Visibility - Consistent, high-quality illumination eliminates shadows where vapor leaks may go unnoticed. Fixtures maintain 90% lumen output for their entire service life to support ongoing safety monitoring, results may vary.

- Instant Full-Power Operation - LEDs reach 100% brightness instantly depending on model, delivering immediate visibility during emergencies without metal halide warm-up or restrike delays.

- Simplified Retrofit Installation - Universal 120-277V drivers integrate with existing wiring. Pre-wired junction boxes maintain hazardous-location sealing requirements while reducing installation labor and downtime.

According to the U.S. Department of Energy's solid-state lighting research, LED technology in industrial applications can achieve significant energy savings while maintaining superior light quality and operational reliability. The DOE's industrial LED lighting guidance demonstrates how facilities can reduce maintenance costs and improve safety through proper LED fixture selection, particularly important in hazardous locations where maintenance access is restricted, and safety protocols are critical.

Essential Safety and Performance Certifications

LED Lighting Supply's expertise ensures our fixtures carry essential certifications, including DLC Premium for energy efficiency and rebate eligibility, UL Listed and ETL Listed for electrical safety and compliance. These certifications support safety, performance reliability, and utility rebate qualification. DLC Premium certification ensures the highest efficiency standards and maximum rebate eligibility for your lighting investment.

The DesignLights Consortium (DLC) maintains rigorous standards for commercial and industrial LED lighting products to ensure maximum energy efficiency and performance reliability. DLC Qualified Products List criteria require comprehensive testing and verification of photometric performance, electrical characteristics, and long-term reliability, ensuring that certified fixtures deliver the promised energy savings and operational benefits throughout their service life.

Comprehensive 5-Year Warranty with USA-Based Support

All our fixtures include a comprehensive 5-year warranty backed by experienced support teams based in the USA. We take customer support seriously, recognizing that keeping your safety lighting operational is critical to personnel protection and regulatory compliance. Our warranty support team understands the importance of maintaining continuous lighting operation and works quickly to resolve any performance issues.

With over 15 years of experience in hazardous location applications, we engineer solutions that protect your facility while delivering the energy savings and operational reliability your project demands. Request a quote from our hazardous location specialists to ensure your Class 1 Division 2 lighting meets exact safety requirements while maximizing long-term value.

Expert Specification Support for Your Hazardous Location Project

LED Lighting Supply's experienced Product Specialists provide complimentary custom lighting layouts specifically designed for your Class 1 Division 2 facility. Our team analyzes your exact hazardous material groups, ambient conditions, and mounting requirements to recommend optimal fixture placement and wattage selections. We deliver detailed energy savings calculations showing your exact return on investment, including current energy costs versus projected LED operating expenses.

Common Mistakes and How to Avoid Them

After working on hundreds of hazardous location installations, we see the same critical mistakes that compromise safety and create expensive compliance failures:

- Using standard industrial fixtures in Class 1 Division 2 areas, thinking they meet requirements. Only fixtures specifically rated and certified for hazardous locations provide proper ignition protection.

- Mixing up temperature classifications during spec. A fixture rated T3 won't work in areas exceeding 200C surface temperature limits, regardless of proper electrical classification.

- Installing threaded rigid conduit without proper explosion-proof fittings. Every joint and connection must maintain the same hazardous rating as your fixtures, or you create ignition paths.

- Mounting fixtures where maintenance will require hot work permits. Place lights away from potential leak points so you can service them without shutting down operations.

- Skipping the conduit seals required within 18 inches of enclosures. Missing seals let vapors travel through your conduit system and defeat the whole protection scheme.

- Running standard wire nuts or Wagos inside explosion-proof junction boxes. Use only approved connection methods that maintain the enclosure's integrity under fault conditions.

LED Lights for Class 1 Division 2 Hazardous Locations Frequently Asked Questions

What is Class I Division 2 LED lighting?

Class I Division 2 LED fixtures are certified for environments where flammable gases or vapors occur only during abnormal conditions such as equipment failure, container leakage, or system malfunction. These fixtures must be UL844-certified with specific Class I Division 2 markings and matched to your hazardous material group (A, B, C, or D).

What hazardous material groups require Class I Division 2 fixtures?

Group A (acetylene) requires the most restrictive fixtures due to extremely low ignition energy. Group D (propane, gasoline, methane, butane, benzene) represents the most frequently encountered flammable vapors. Groups B and C cover hydrogen and ethylene respectively - each group requires fixtures certified for that specific classification.

When should I use Class I Division 2 LED fixtures?

Use these fixtures when hazardous atmospheres occur only during abnormal conditions and normal operations properly contain flammable materials - such as storage areas, loading docks, and equipment rooms with adequate ventilation. Fixtures provide 50,000+ hour operation and 100% brightness instantly without warm-up delays.

When should I NOT use Class I Division 2 LED fixtures?

Do not use when hazardous atmospheres exist during normal operations - paint mixing rooms, tank interiors, and process vessels require Division 1 protection. Do not use in Class II combustible dust environments or when fixture T-rating exceeds the ignition temperature of materials present.

What certifications should Class I Division 2 fixtures have?

Require fixtures that are UL Listed or ETL Listed with specific Class I Division 2 markings. DLC Premium certification ensures highest efficiency standards and maximum rebate eligibility. All fixtures must be certified by nationally recognized testing laboratories and evaluated per NEC, UL, and CSA standards.

What is a T-rating and why does it matter?

T-rating indicates the maximum surface temperature a fixture reaches during operation. The fixture T-rating must stay below the ignition temperature of specific materials present in your environment - a fixture rated T3 will not work in areas exceeding 200 degrees C surface temperature limits.

What conduit and seal requirements apply?

All connections need explosion-proof fittings and seals within 18 inches of enclosures. Standard fittings and missing seals create dangerous ignition paths. Every joint and connection must maintain the same hazardous rating as your fixtures.

How much energy do Class I Division 2 LED fixtures save?

LED fixtures reduce electricity consumption by 65% compared to metal halide, model dependent. Lower power draw produces less heat, which helps maintain safe temperatures in enclosed hazardous environments.

What applications use Class I Division 2 lighting?

Applications include aircraft maintenance hangars requiring wide beam distribution for jet fuel vapor areas, covered fueling operations needing Group D certified fixtures, automotive paint booths requiring CRI 80+ performance, oil and gas refineries, bulk fuel storage terminals, and chemical tank farms.

What warranty and support is available?

Fixtures include a 5-year warranty backed by USA-based support. Final selection should be validated with a photometric plan and confirmed by a licensed professional when required for code- or safety-critical areas.