Showing 1–12 of 30 results

- SKU:MLLG-LED-HT80-50-110-[V] | Web ID:1317100V-277V:103 In StockShips 2-3 Days277V-480V:Built to Order 6 Weeks

- Watts: 50

- Lumens: 6500

- Lumens/Watt: 130

- Replaces: 175 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 110°

- Beam Angle (Opt): 30° | 90° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 12.1 X 14.4 X 9.6 in

- Weight: 17.2 lbs

Starting At$439.60 - SKU:MLLG-LED-HT80-100-50-110-[V] | Web ID:1318100V-277V:166 In StockShips 2-3 Days277V-480V:Built to Order 6 Weeks

- Watts: 100

- Lumens: 13000

- Lumens/Watt: 130

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 110°

- Beam Angle (Opt): 30° | 90° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 12.1 X 14.4 X 9.6 in

- Weight: 17.2 lbs

Starting At$539.15 - SKU:MLLG-LED-HT80-150-50-110-[V] | Web ID:1319100V-277V:111 In StockShips 2-3 Days277V-480V:Built to Order 6 Weeks

- Watts: 150

- Lumens: 19500

- Lumens/Watt: 130

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 110°

- Beam Angle (Opt): 30° | 90° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 15.8 X 14.4 X 9.6 in

- Weight: 20.75 lbs

Starting At$649.29 - SKU:MLLG-LED-HT80-200-50-110-[V] | Web ID:1320100V-277V:58 In StockShips 2-3 Days277V-480V:Built to Order 6 Weeks

- Watts: 200

- Lumens: 26000

- Lumens/Watt: 130

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 110°

- Beam Angle (Opt): 30° | 90° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 19.5 X 14.4 X 9.6 in

- Weight: 26.20 lbs

Starting At$870.24 - SKU:MLLG-LED-HT80-300-50-90-[V] | Web ID:1321100V-277V:Built to Order 6 Weeks277V-480V:Built to Order 6 Weeks

- Watts: 300

- Lumens: 39000

- Lumens/Watt: 130

- Replaces: 1000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No | 1-10V

- Beam Angle (Std): 90°

- Beam Angle (Opt): 30° | 110° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 26.9 X 14.4 X 9.6 in

- Weight: 42.55 lbs

Starting At$1,305.20 - SKU:MLLG-LED-HT80-450-50-90-[V] | Web ID:1322100V-277V:Built to Order 8 Weeks277V-480V:Built to Order 8 Weeks

- Watts: 450

- Lumens: 58500

- Lumens/Watt: 130

- Replaces: 1000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 90°

- Beam Angle (Opt): 30° | 110° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 38.0 X 14.4 X 9.6 in

- Weight: 61.7 lbs

Starting At$1,816.62 - SKU:MLLG-LS-LED-HB-40-[Color]-HT-[V] | Web ID:1735100V-277V:Built to Order 6 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 40

- Lumens: 6000

- Lumens/Watt: 150

- Replaces: 150 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 8.5 X 12 X 8.65 in

- Weight: 12 lbs

Starting At$542.91 - SKU:MLLG-LS-LED-HB-100-[Color]-HT-[V] | Web ID:1323100V-277V:Built to Order 6 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 100

- Lumens: 13000

- Lumens/Watt: 130

- Replaces: 250 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 12 X 12 X 8.65 in

- Weight: 13.2 lbs

Starting At$956.37 - SKU:MLLG-LS-LED-HB-150-[Color]-HT-[V] | Web ID:1324100V-277V:Built to Order 6 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 150

- Lumens: 19500

- Lumens/Watt: 130

- Replaces: 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 14.17 X 13.77 X 8.65 in

- Weight: 19 lbs

Starting At$1,442.00 - SKU:MLLG-LS-LED-HB-200-[Color]-HT-[V] | Web ID:1325100V-277V:Built to Order 6 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 200

- Lumens: 26000

- Lumens/Watt: 130

- Replaces: 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 18.11 X 14.17 X 8.65 in

- Weight: 24.6 lbs

Starting At$1,959.92 - SKU:MLLG-LS-LED-HB-300-[Color]-HT-[V] | Web ID:1326100V-277V:Built to Order 8 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 300

- Lumens: 39000

- Lumens/Watt: 130

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 19.6 X 16.53 X 8.65 in

- Weight: 38.3 lbs

Starting At$2,837.92 - SKU:MLLG-LS-LED-HB-400-[Color]-HT-[V] | Web ID:1327100V-277V:Built to Order 8 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 400

- Lumens: 52000

- Lumens/Watt: 130

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 22 X 20.86 X 8.65 in

- Weight: 45.8 lbs

Starting At$3,662.64

What Are Industrial LED High Temperature Lights?

Standard LED fixtures fail rapidly when exposed to temperatures beyond their design limits. The combination of ambient heat plus fixture-generated heat must stay below the maximum operating temperature, or you will face premature failure and voided warranties. After 15+ years of working with industrial clients, we have seen many projects where standard lighting could not survive high temperature environments.

High temperature LED lights feature specialized heat-resistant components, IP66 waterproof protection, and engineered thermal management systems. The key difference is in component selection and thermal design. While standard fixtures operate near their maximum capacity, our high-temperature models maintain significant thermal headroom. This allows them to handle extreme temperatures from -85°F to 392°F while maintaining full lumen output, depending on model and site conditions.

We typically see these industrial LED lights used in steel mills, foundries, and power generation facilities where temperatures routinely exceed 200°F. The main advantage is reliable illumination as temperatures climb, plus extended fixture lifespan with minimal maintenance. Most customers choose these when their existing lighting fails frequently due to heat exposure.

Many high-temperature fixtures also excel in extreme cold. Our models rated for 194°F and 392°F operation can also function at -85°F, making them suitable for both desert installations and cold storage facilities where standard LEDs would fail.

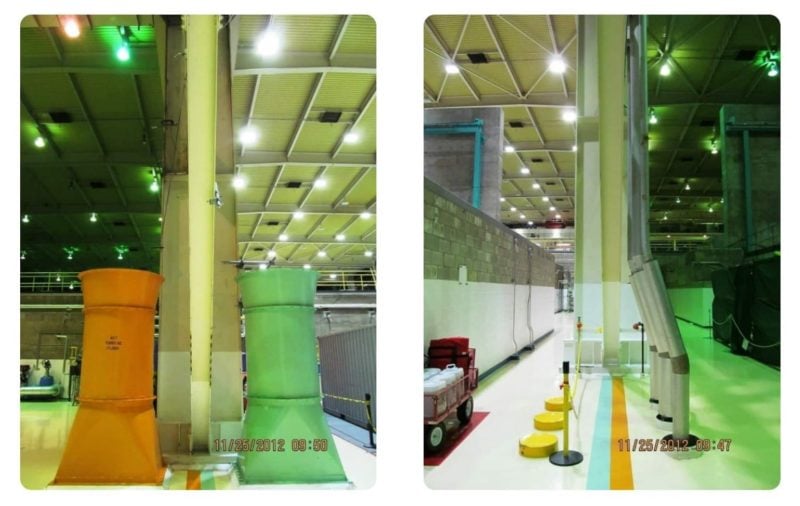

A nuclear power plant in Michigan installed our LED high temp fixtures.

Understanding the Heat Resistant Properties of High Temp LED Lights

- High-temperature LED engineering focuses on three critical areas: component selection, heat dissipation, and protective housing design. Premium LED chips rated for higher junction temperatures combine with drivers featuring wider operating ranges and advanced heat sink designs that dissipate heat more effectively than standard fixtures.

- The power supply technology deserves special attention. Power supplies in heat-resistant fixtures are oversized and under-driven for maximum thermal headroom. A 200-watt driver powering a 100-watt fixture generates minimal thermal heat while providing exceptional reliability margins.

- Housing construction involves specialized gaskets, heat-resistant powder coating, and reinforced mounting hardware. Oversized heat-sinks dramatically exceed standard cooling capacity to dissipate extreme thermal loads effectively.

- Many configurations include additional LED chips operated below maximum capacity. Under-driving the LED array significantly extends the operating temperature range while maintaining consistent light output even in brutal thermal conditions.

- Energy efficiency remains strong even at high temperatures. While standard LEDs lose significant efficacy as temperatures rise, our high-temperature models typically maintain 90-95% of their rated output throughout their operating temperature range. This translates to consistent light levels and lower operating costs compared to traditional high-temperature lighting solutions.

The U.S. Department of Energy emphasizes the importance of thermal management in LED performance and efficiency. According to the DOE's LED lighting guidance, proper heat dissipation is critical for maintaining LED lifespan and light output, as elevated temperatures can significantly reduce LED efficiency and accelerate lumen depreciation in standard fixtures.

An aluminum smelting facility in the Middle East with our high-temperature LED lights installed

Quick Selection Guide

- Use high-temperature LED fixtures when ambient temperatures exceed 130°F or standard LEDs fail frequently due to heat exposure

- Choose 150W-200W models for 20-30 foot ceiling heights with 60-degree beam angles spaced 25-30 feet apart

- Verify maximum operating temperature (-85°F to 392°F range varies by model - check specific datasheets)

- Select IP66-rated models for applications with moisture, dust, or chemical exposure combined with high heat

- Request photometric analysis for fixture count, placement, and expected light levels in your specific space

Tip: Never mount fixtures directly in furnace exhaust streams or superheated air flows - even 392°F-rated fixtures can be damaged by direct exposure to thermal plumes.

Use When / Don't Use When

Use High Temperature LED Lights When

- Ambient temperatures exceed 130°F, or standard LEDs fail within 2-3 years due to heat

- Industrial environments include steel mills, foundries, power plants, aluminum smelting, or glass manufacturing

- Continuous high-temperature operation is required, not just brief heat exposure

- Combined thermal challenges include heat plus dust, moisture, vibration, or chemical exposure

- Maintenance access is limited, and you need a 10+ year fixture lifespan in harsh conditions

Don't Use High Temperature LED Lights When

- Standard ambient conditions remain below 130°F with normal HVAC control

- Budget constraints exist, and heat exposure is only occasional or brief

- Direct thermal plume exposure from furnaces or stacks exceeds fixture ratings

- Explosion-proof requirements are needed without verifying specific model certifications

- Rapid temperature cycling creates thermal shock beyond fixture design limits

What We Verify Before You Order

We confirm

- Maximum ambient temperature and heat source locations

- Ceiling height and mounting structure thermal expansion

- Required light levels and uniformity for your operations

- Environmental conditions (moisture, dust, chemicals, vibration)

- Electrical requirements and any special certifications needed

If we provide a lighting plan, you will get

- Exact fixture count, wattage, and placement recommendations

- Expected foot-candle levels and uniformity ratios throughout your space

- Mounting specifications and thermal consideration guidance

Note: Guidance is general planning information. Final selection should be validated with a photometric plan and confirmed by a licensed professional when required for code- or safety-critical areas.

What are the Best Applications for LED High Temperature Lights?

Over 15+ years, we have installed thousands of high-temperature fixtures across diverse industries worldwide. Our track record spans from California desert facilities to Middle Eastern industrial complexes, each presenting unique thermal challenges that have refined our application expertise.

| Power Generation Facilities | Nuclear plants, coal-fired facilities, and natural gas plants all require lighting that withstands intense heat from steam turbines and boiler operations. For high-bay applications in power generation environments, we typically recommend 150W to 240W fixtures with 120-degree beam angles. |

| Manufacturing Applications | Includes aluminum smelting, steel production, glass manufacturing, and metal foundries. Heat combines with dust, moisture, and vibration in demanding industrial environments. |

| Power Plants | Steam turbine areas benefit most from 200-400W models using pendant mounting for easy maintenance access. Radiant heat from turbine operations requires fixtures that maintain consistent illumination throughout critical facility operations. |

| Nuclear Facilities | Require specialized safety cables and documentation that we provide as standard equipment. Reactor building applications need fixtures meeting stringent safety requirements while delivering reliable performance in controlled environments. |

| Aluminum Smelting | Needs IP66 protection against molten metal splash combined with extreme temperature resistance. Potline installations work best with 150W units featuring reinforced housings designed for harsh smelting conditions. |

| Pulp & Paper Mills | Face humid, corrosive conditions plus high heat from drying processes. Stainless steel hardware prevents corrosion while maintaining consistent light output in chemically aggressive environments. |

| Steel Mills | Require fixtures that survive radiant heat from furnaces and rolling operations. Chain mount configurations allow fixtures to move with building thermal expansion while maintaining proper illumination angles. |

| Natural Gas Processing Plants | Benefit from explosion-proof mounting options available with our high-temperature models. Hazardous location requirements combine with extreme heat challenges in gas processing applications. |

| Glass Manufacturing | Requires precise temperature control, as standard lighting can disrupt thermal processes. Low-heat LED technology maintains illumination without affecting glass-forming operations or temperature-sensitive manufacturing processes. |

| Metal Foundries | Present the ultimate test with molten metal, extreme heat, and heavy dust contamination. Our 392°F-rated models with completely sealed housings perform reliably in these brutal foundry conditions. |

| Electric Arc Furnace Buildings | Experience rapid temperature swings that destroy standard fixtures instantly. Advanced thermal management systems handle dramatic temperature fluctuations while maintaining consistent light output throughout heating cycles. |

| General Industrial Manufacturing | Facilities near ovens, kilns, or heat-treating equipment rely on heat-resistant fixtures. Standard mounting configurations work effectively since temperatures rarely exceed 200°F in general manufacturing applications. |

OSHA's workplace safety guidelines emphasize the importance of adequate lighting in industrial environments, particularly those involving high temperatures and hazardous conditions. The Occupational Safety and Health Administration's standards specify minimum illumination levels for industrial facilities and highlight how proper lighting contributes to worker safety in high-temperature and hazardous manufacturing environments.

Our High temperature light installed in the Middle East

How Many High Temperature Lights Do I Need?

Fixture count depends on your specific application, ceiling height, and required light levels. Most industrial facilities need 20-50 foot-candles for general operations, while detailed work requires 50-100 foot-candles. We can typically replace existing HID fixtures one-for-one, while significantly improving light levels.

Computer-generated lighting plans provide the most accurate fixture count and placement recommendations. Photometric analysis models your exact space dimensions, existing conditions, and lighting requirements to specify optimal fixture wattages, quantities, locations, and expected light levels throughout your facility.

Free lighting plans for all commercial and industrial projects eliminate guesswork and ensure optimal performance before installation begins. This service saves time and money while guaranteeing proper illumination levels.

LED vs Metal Halide: Energy Savings Guide

Based on 168 hours per week operation at $0.18/kWh

60 Watt LED replaces 250W Metal Halide |

Annual Energy Cost Savings:

$357.74 per fixture 5-Year Savings: $1,788.70 per fixture 5-Year Savings for 20 Fixtures: $35,773.92 |

150 Watt LED replaces 400W Metal Halide |

Annual Energy Cost Savings:

$487.47 per fixture 5-Year Savings: $2,437.34 per fixture 5-Year Savings for 20 Fixtures: $48,746.88 |

300 Watt LED replaces 1000W Metal Halide |

Annual Energy Cost Savings:

$1,336.61 per fixture 5-Year Savings: $6,683.04 per fixture 5-Year Savings for 20 Fixtures: $133,660.80 |

600 Watt LED replaces 1500W Metal Halide |

Annual Energy Cost Savings:

$1,769.04 per fixture 5-Year Savings: $8,845.20 per fixture 5-Year Savings for 20 Fixtures: $176,904.00 |

LED Lighting Supply High Temperature Lighting Plan Example

Fabric Processing Facility

- Mounting height: 21-37 ft

- Fixture Used: 150 Watt LED High Temperature Light | 19500 Lumens | 5000K | 100V-277V or 277V-480V | Rated to 176F and 200 Watt LED High Temperature Light | 26000 Lumens | 5000K | 100V-277V or 277V-480V | Rated to 176F

- FC achieved: 47 FC average

- Uniformity: 2.1

Are There Any Special Considerations When Installing Your High-Temperature LED Lights?

Installation follows standard high bay mounting procedures, but thermal considerations require careful attention. Avoid mounting fixtures directly in furnace exhaust streams or areas where radiant heat exceeds the fixture's ambient temperature rating. Even our 392°F rated fixtures can be damaged by direct exposure to superheated air streams.

Nuclear facilities require safety cables and documentation meeting industry safety standards that we provide with every order. Vibration-resistant mounting hardware works best for applications near heavy machinery or processing equipment that generates continuous vibration.

Driver placement becomes more critical in extreme heat applications. Built-in thermal protection prevents damage, but proper ventilation around fixture housing optimizes performance and extends operational life significantly.

Stock inventory ensures quick delivery with complete installation accessory packages available immediately. Most projects ship within 3-5 business days with all necessary mounting hardware and accessories included for immediate installation.

Important: Final fixture selection and installation must comply with local electrical codes, OSHA, and NFPA requirements and must be performed by qualified, licensed professionals.

What are the Benefits of Using LED Heat Resistant Lights?

- Energy Reduction: Facilities typically see 60-80% energy savings compared to metal halide or high-pressure sodium fixtures, depending on model and site conditions. The efficiency advantage is even greater in hot environments where traditional lighting struggles.

- Maintenance Elimination: No bulbs or ballasts to replace means dramatically reduced maintenance costs. Most customers report maintenance intervals extending from monthly to annual or longer, when properly specified.

- Extended Lifespan: While standard LEDs might last 2-3 years in high-heat environments, our heat-resistant models deliver 10+ years of reliable operation with minimal lumen depreciation when properly specified.

- Industrial-Grade Construction: Engineered for temperatures up to 392°F (verify on fixture spec sheets), these fixtures include vibration resistance, impact protection, and corrosion-resistant materials needed in demanding settings.

- Immediate Full Output: Unlike HID lighting that requires warm-up time, these LEDs reach full brightness instantly, even at high ambient temperatures.

- Superior Light Quality: Available in 4000K and 5000K color temperatures with high CRI ratings, providing better visibility and safety in industrial applications.

- Safety Certifications: UL Listed and DLC Premium certifications per listed certifications ensure safety compliance while qualifying projects for utility rebates and tax incentives.

DOE Guidance: Industrial lighting efficiency standards are well-documented by the U.S. Department of Energy, which reports that LED lighting in commercial and industrial applications can reduce energy consumption by 50-90% compared to conventional technologies, with the highest savings achieved in high-temperature environments where traditional lighting operates at reduced efficiency.

Nuclear power plant in Alabama with our LED lights installed (green lights are the old mercury vapor lights that were being replaced)

Safety and Performance Certifications

All our fixtures carry essential certifications, including DLC Premium, UL Listed, and ETL Listed approvals. These certifications ensure safety, performance, and energy efficiency while qualifying your project for utility rebates and tax incentives. DLC Premium certification guarantees the highest efficiency standards and maximum rebate eligibility.

5-Year Warranty and Support

All our lights come with at least a 5-year warranty, and all warranty support is based in the USA. We take customer support seriously, and helping you with a warranty claim is important to us. Our experienced support team understands the importance of keeping your lighting operational and will work quickly to resolve any warranty issues.

Need Help? Talk to an LED Lighting Supply High Temperature Lighting Expert.

Selecting the right high-temperature lighting requires understanding your specific thermal conditions, mounting requirements, and performance expectations. Our sales engineers have extensive experience with challenging industrial applications and can recommend the optimal solution for your facility.

We will evaluate your current fixtures, ambient conditions, and lighting requirements to specify the appropriate wattage, beam angle, and mounting configuration. Our free lighting plan service eliminates uncertainty and ensures proper light levels and uniformity before you invest in new fixtures.

Contact our team for expert guidance and a free lighting plan tailored to your high-temperature application.

Common Mistakes and How to Avoid Them

- Installing standard LEDs in any ambient temperature over 130°F kills fixtures fast - always verify actual high-temperature ratings on datasheets.

- Mounting fixtures directly above heat sources without considering radiant temperature - keep fixtures out of direct thermal plumes from furnaces and hot equipment.

- Skipping thermal calculations by adding ambient temperature plus fixture heat generation - this determines actual operating conditions.

- Using fixtures rated for maximum temperature but not continuous operation - industrial applications need sustained high-temperature ratings.

- Ignoring airflow patterns around fixtures - hot stagnant air around heat sinks shortens life even when ambient ratings seem adequate.

- Choosing fixtures without proper IP ratings - steam, dust, and chemical vapors are more aggressive at elevated temperatures.

- Installing too few fixtures to avoid heat generation creates safety problems - use lower-wattage fixtures instead of fewer high-wattage units in extreme heat areas.

- Mounting fixtures on structures that expand and contract thermally causes mechanical stress and connection problems over time.

Industrial LED High Temperature Lights - Up to 392°F Frequently Asked Questions

What temperature range can high-temperature LED lights operate in?

Operating range varies by model from -85°F to 392°F - verify the specific rating on fixture datasheets before ordering since maximum temperature varies between models.

When should I use high-temperature LED lights instead of standard LEDs?

Use high-temperature LEDs when ambient temperatures exceed 130°F or when standard LEDs fail within 2-3 years due to heat exposure in environments like steel mills, foundries, power plants, or glass manufacturing.

When should I NOT use high-temperature LED lights?

Do not use when ambient conditions remain below 130°F with normal HVAC, when direct thermal plume exposure from furnaces exceeds fixture ratings, or when rapid temperature cycling creates thermal shock beyond fixture design limits.

What certifications do your high-temperature LED fixtures carry?

Fixtures carry DLC Premium, UL Listed, and ETL Listed certifications, qualifying projects for utility rebates and tax incentives.

How much energy can I save by switching to high-temperature LEDs?

Facilities see 60-80% energy savings compared to metal halide or high-pressure sodium fixtures, depending on model and site conditions.

What IP rating do high-temperature LED fixtures have?

Select IP66-rated models for applications combining high heat with moisture, dust, or chemical exposure.

How long do high-temperature LED lights last?

Heat-resistant models deliver 10+ years of reliable operation when properly specified, compared to 2-3 years for standard LEDs in high-heat environments.

What wattage should I choose for my ceiling height?

Choose 150W-200W models for 20-30 foot ceiling heights with 60-degree beam angles spaced 25-30 feet apart - request a photometric analysis for exact fixture count and placement.

Can I mount fixtures directly above furnaces or heat sources?

Never mount fixtures directly in furnace exhaust streams or superheated air flows - even 392°F-rated fixtures can be damaged by direct exposure to thermal plumes.

Do you offer free lighting plans for high-temperature applications?

Free lighting plans for commercial and industrial projects include exact fixture count, wattage, placement recommendations, and expected foot-candle levels throughout your space.

What color temperatures are available?

Available in 4000K and 5000K color temperatures with high CRI ratings for better visibility and safety in industrial applications.

What warranty do high-temperature LED fixtures include?

All fixtures include at least a 5-year warranty with USA-based support.

How quickly can high-temperature fixtures ship?

Stock inventory ships within 3-5 business days with all necessary mounting hardware and accessories included.

What industries commonly use high-temperature LED lighting?

Steel mills, aluminum smelting, glass manufacturing, power generation facilities, nuclear plants, metal foundries, and pulp and paper mills where temperatures routinely exceed 200°F.

Do high-temperature LEDs work in cold environments too?

Models rated for 194°F and 392°F operation also function at -85°F, making them suitable for both desert installations and cold storage facilities.

![Mllg Led Ht80 100 50 110 [3]](https://www.ledlightingsupply.com/wp-content/uploads/2019/05/MLLG-LED-HT80-100-50-110-3-800x800.jpg)