Showing 1–12 of 36 results

- SKU:MLLG-LED-HB3-200-50-120 | Web ID:1952Availability: 1135 In Stock Ships 2-3 Days

- Watts: 100 | 120 | 150 | 200

- Lumens: 14000 | 16800 | 21000 | 28000

- Lumens/Watt: 140

- Replaces: 250 | 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -22°F to 122°F

- Rated Life: 170,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook

- Mount (Opt): Pendant

- Dimensions: 11.02 X 7.72 Inches

- Cord Length: 5 Feet

- Weight: 5.5 lbs

Starting At$99.72 - SKU:MLLG-LED-HB3-100-50-120 | Web ID:2024Availability: 84 In Stock Ships 2-3 Days

- Watts: 60 | 80 | 100

- Lumens: 8400 | 11200 | 14000

- Lumens/Watt: 140

- Replaces: 150 | 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -22°F to 122°F

- Rated Life: 170,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook

- Mount (Opt): Pendant

- Dimensions: 9.2 X 7.1 Inches

- Cord Length: 5 Feet

- Weight: 3.5 lbs

Starting At$82.99 60 / 80 / 100 Watt Adjustable UFO High Bay | 9600 to 16000 Lumens | 3500K / 4000K / 5000K | 100-277V

SKU:LLS-M-HB6-100A-CC | Web ID:2671Back in Stock 3/20- Watts: 60 | 80 | 100

- Lumens: 9600 | 12800 | 16000

- Lumens/Watt: 160

- Replaces: 250 Watt Metal Halide

- Color Temp: 3500K | 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 hours

- Dimmable: 0-10V

- Beam Angle (Std): 60° | 90° | 110°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Hook

- Dimensions: 11 X 5 Inches

- Weight: 3.5 lbs

Starting At$80.49- SKU:LLS-HB-200A-CC-[C] | Web ID:2574Black:334 In StockShips 2-3 DaysWhite:38 In StockShips 2-3 Days

- Watts: 120 | 160 | 200

- Lumens: 19800 | 26400 | 33000

- Lumens/Watt: 165

- Replaces: 250 | 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -22°F to 122°F

- Rated Life: 134,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black | White

- Mount: Hook

- Mount (Opt): Pendant | Surface

- Dimensions: 11.8 X 6.6 Inches

- Weight: 5.1 lbs

Starting At$106.21 - SKU:MLLG-LED-HBHO-240-5-120 | Web ID:1528Availability: 150 In Stock Ships 2-3 Days

- Watts: 100 | 120 | 150 | 200 | 240

- Lumens: 20000 | 24000 | 30000 | 40000 | 45600

- Lumens/Watt: 200

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -22°F to 122°F

- Rated Life: 134,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 60° | 90°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook

- Mount (Opt): Pendant | Surface

- Dimensions: 14.7 X 7.32 Inches

- Cord Length: 5 Feet

- Weight: 12 lbs

Starting At$179.64 - SKU:MLLG-AG-LED-HB-300-5-120-[V] | Web ID:980100V-277V:177 In StockShips 2-3 Days277V-480V:244 In StockShips 2-3 Days

- Watts: 300

- Lumens: 45000

- Lumens/Watt: 150

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 70+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V | 277V-480V | 127-300VDC

- Operating Temp: -22°F to 140°F

- Rated Life: 164,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Black

- Mount: Eye-Hook

- Mount (Opt): Pendant | Surface

- Dimensions: 16 X 8 Inches

- Cord Length: 5 Feet

- Weight: 21 lbs

Starting At$353.15 - SKU:LLS-M-HB6-300A-CC-[V] | Web ID:2672100V-277V:Back in Stock 3/20277V-480V:Back in Stock 3/20

- Watts: 200 | 240 | 300

- Lumens: 32000 | 38400 | 48000

- Lumens/Watt: 160

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 3500K | 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 6kV

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 hours

- Dimmable: 0-10V

- Beam Angle (Std): 60° | 90° | 110°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Hook

- Mount (Opt): Pendant

- Dimensions: 14 X 6 Inches

- Weight: 3.5 lbs

Starting At$188.80 - SKU:LLS-X-HB9-150A-CC-[C] | Web ID:2662Black:3224 In StockShips 3-5 DaysWhite:848 In StockShips 2-3 Days

- Watts: 80 | 100 | 150

- Lumens: 12000 | 15000 | 22500

- Lumens/Watt: 150

- Replaces: 250 | 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 113°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Polycarbonate Lens

- Fixture Color: Black | White

- Mount: Hook

- Mount (Opt): Surface

- Dimensions: 7.7 X 10.8 Inches

- Cord Length: 5 Feet

- Weight: 4.5 lbs

Starting At$124.47 - SKU:LLS-X-HB8-150-5-HV | Web ID:2187Availability: 322 In Stock Ships 3-5 Days

- Watts: 150

- Lumens: 21700

- Lumens/Watt: 145

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 277V-480V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Hook

- Mount (Opt): Surface

- Dimensions: 11.6 X 8.5 Inches

- Cord Length: 5 Feet

- Weight: 10 lbs

Starting At$180.00 - SKU:LLS-X-HB9-240A-CC-[C] | Web ID:2564White:444 In StockShips 2-3 DaysBlack:1053 In StockShips 3-5 Days

- Watts: 150 | 200 | 240

- Lumens: 22500 | 30000 | 36000

- Lumens/Watt: 150

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black | White

- Mount: Hook | Pendant

- Mount (Opt): Surface

- Dimensions: 12 X 7.8 Inches

- Cord Length: 5 Feet

- Weight: 7.5 lbs

Starting At$139.15 - SKU:LLS-X-HB8-240-5-HV | Web ID:2213Availability: 347 In Stock Ships 3-5 Days

- Watts: 240

- Lumens: 36000

- Lumens/Watt: 150

- Replaces: 1000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 277V-480V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Hook | Pendant

- Mount (Opt): Surface

- Dimensions: 12.8 X 9.1 Inches

- Cord Length: 5 Feet

- Weight: 8 lbs

Starting At$220.19 - SKU:LLS-X-HB8-310/270/240-CC | Web ID:2211Availability: 733 In Stock Ships 3-5 Days

- Watts: 240 | 270 | 310

- Lumens: 34800 | 39150 | 45000

- Lumens/Watt: 145

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 110°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Hook | Pendant

- Mount (Opt): Surface

- Dimensions: 14 x 11 Inches

- Cord Length: 5 Feet

- Weight: 11 lbs

Starting At$189.44

What Are LED Warehouse Lights?

LED warehouse lights are high-output, energy-efficient fixtures engineered to illuminate large indoor spaces such as warehouses, distribution centers, and industrial storage facilities. They typically take the form of UFO and linear LED high bay lights mounted at heights from 15 to 65 feet. Our warehouse lights deliver bright, uniform light for aisles, racking, and open floor areas. Unlike metal halide or fluorescent legacy lighting, our LED warehouse lights provide instant-on performance, 50-75% energy savings, reduced maintenance, and consistent, reliable light quality.

Transform Your Warehouse Operations with Professional LED High Bay Lighting Solutions

With over 15 years of LED warehouse lighting industry experience, LED Lighting Supply's Product Specialists understand the critical role that proper illumination plays in warehouse productivity, safety, and operational costs. Facilities using professionally designed high bay LED systems typically achieve 65% energy reduction while improving worker safety and operational efficiency.

The U.S. Department of Energy's solid-state lighting program demonstrates that LED lighting in commercial and industrial facilities can reduce energy consumption by 50-75% compared to traditional high-intensity discharge systems, with many warehouse applications achieving the higher end of this range due to improved efficacy and advanced controls integration.

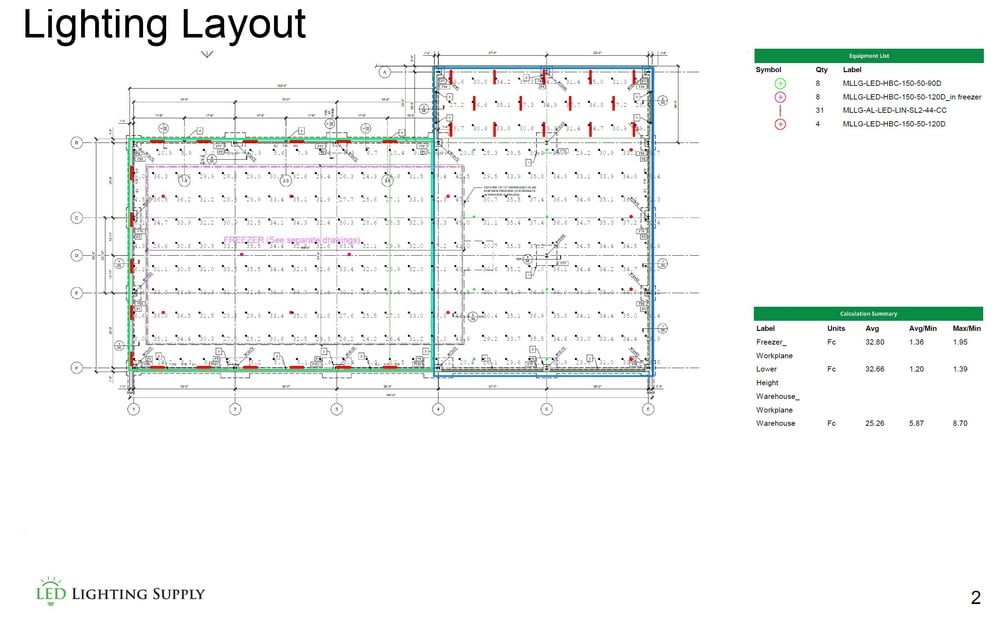

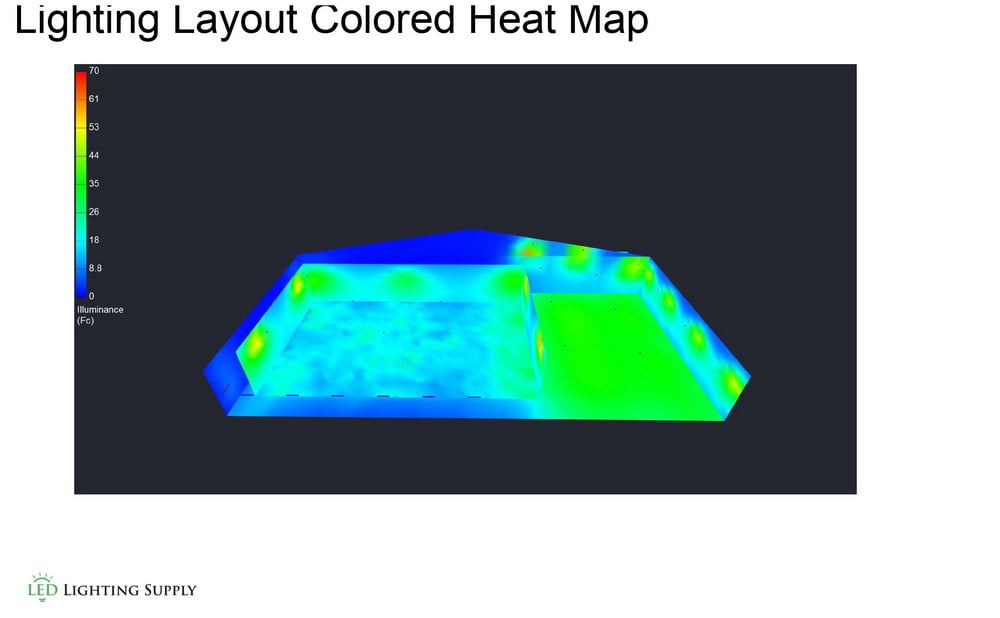

Case Study: Installation of new LED Lighting for Old Souls Farm in Saint Paris, OH

|

After: 150 Watt High Output UFO High Bay | 22500 Lumens |

|

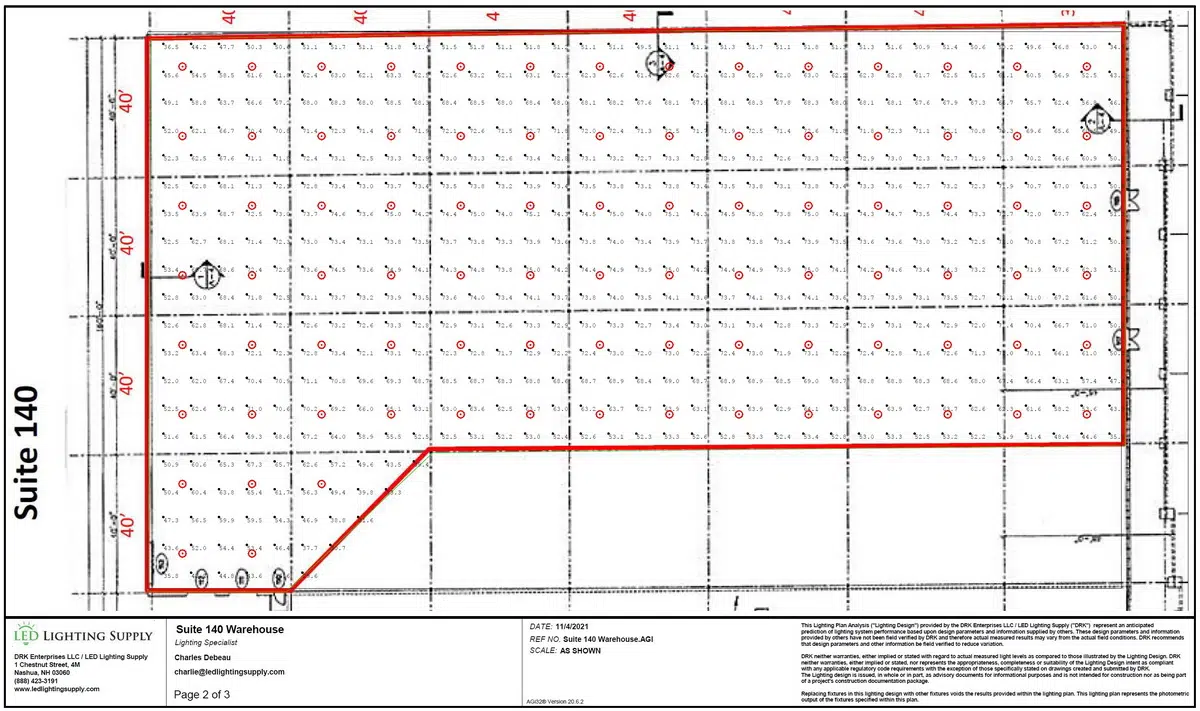

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

Warehouse / Cold Storage Lighting Installation Plan Metrics

- Mounting height: 23 to 32 ft

- Fixture Used: MLLG-LED-HBC-200-5-120: 100 / 120 / 150 / 200 Watt Adjustable LED UFO High Bay | 15000 to 30000 Lumens

- FC achieved: 25.26 FC average

- Uniformity (Avg/Min): 1.36

Use When / Don't Use When

Use LED Warehouse Lights When

- Replacing 400W+ metal halide or fluorescent systems with documented warm-up delays and high energy costs

- Ceiling heights range 15-65 feet where proper fixture spacing and beam angles can be calculated

- Facility requires instant-on performance for safety, productivity, or frequent cycling operations

- Environmental durability is needed such as IP65+ moisture protection or IK impact resistance (UFO models)

- Long-term energy savings are priority with 50-75% consumption reduction compared to HID systems

Don't Use LED Warehouse Lights When

- Ceiling height is below 15 feet where high bay fixtures create glare and over-illumination

- Hazardous location ratings are required without confirming specific Class/Division certifications on datasheet

- Extreme temperature environments exist without verifying operating range specifications for your conditions

- Precision color work is critical and you need CRI above 80 (most warehouse LEDs provide 70+ CRI)

- Budget only allows lowest-cost fixtures without considering total cost of ownership including energy and maintenance

What We Verify Before You Order

We confirm

- Ceiling height and mounting constraints

- Required foot-candle levels by zone

- Existing electrical voltage (120-277V or 277-480V)

- Environmental conditions (moisture, impact, temperature)

- Control requirements (motion sensors, dimming, emergency backup)

If we provide a lighting plan, you will get

- Precise fixture placement with spacing calculations

- Average foot-candle levels and uniformity ratios

- Photometric analysis using professional AGI32 software

Note: Guidance is general planning information. Final selection should be validated with a photometric plan and confirmed by a licensed professional when required for code- or safety-critical areas.

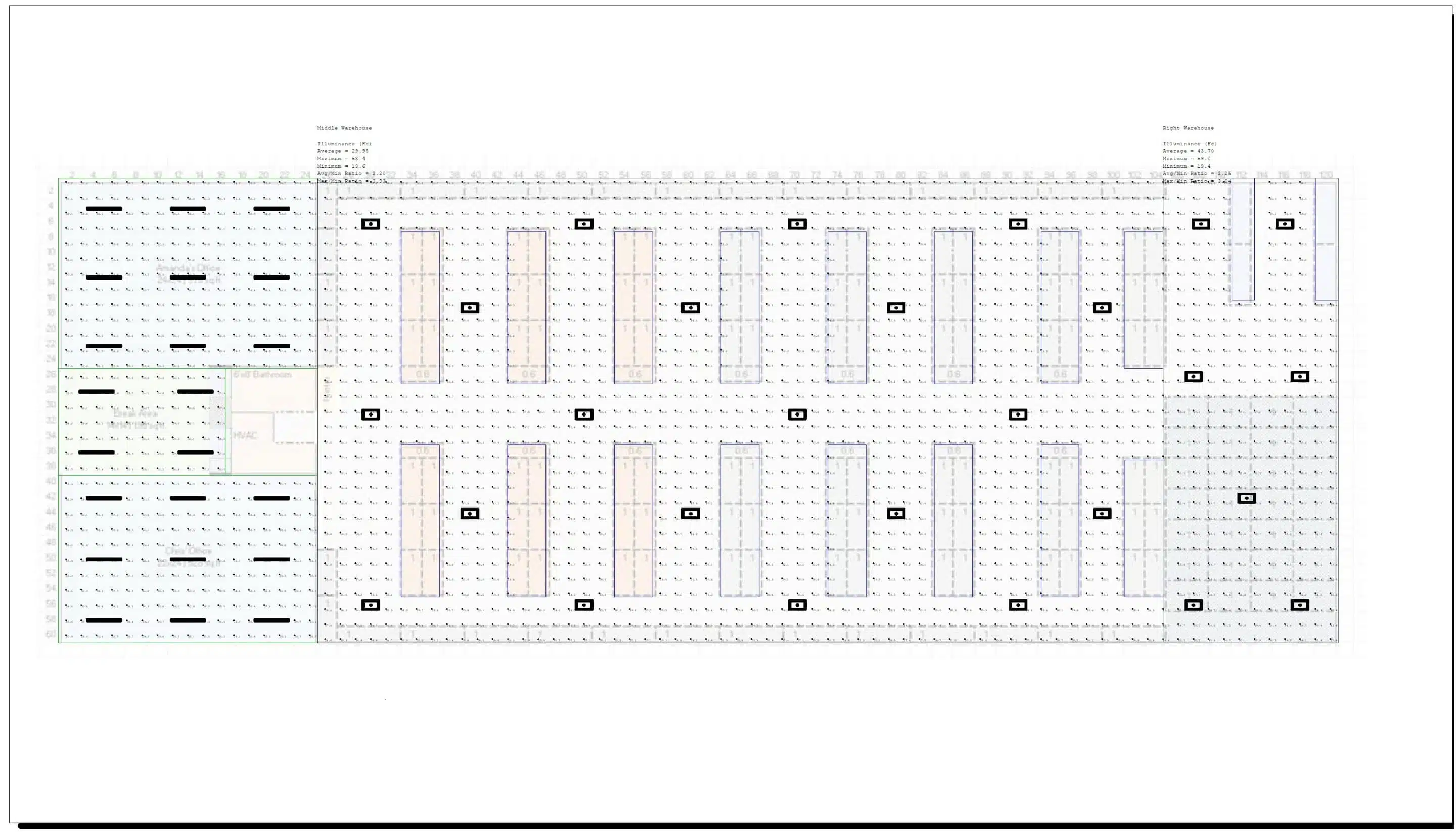

Case Study: Conversion of (72) T5 6 tube fixtures to LED Lighting Supply 200 Watt LED UFO Fixtures (one-for-one replacement) in Williston, ND

|

Before: T5 54W HO Fluorescent Fixtures |

After: 200 W LED UFO Fixtures |

|

|

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

LED High Bays Warehouse Installation Lighting Plan Metrics

- Mounting height: 20 ft

- Fixture Used: MLLG-LED-HBC-200-5-120: 100 / 120 / 150 / 200 Watt Adjustable LED UFO High Bay | 15000 to 30000 Lumens | 5000K | 100-277V | White Housing

- FC achieved: 60.33 FC average

- Uniformity (Avg/Min): 1.42

Case Study LED High Bays Warehouse Installation Energy Savings: 200W LED vs 324W Fluorescent Replacement (with ballast)

Assumptions: Based on 18 hours/day, 300 days/year at $0.08/kWh

| Fluorescent (373W) | Annual Energy Cost: $160.96 5 Year Energy Cost: $804.82 5 Year Savings: $0.00 |

| LED UFO Fixture (200W) | Annual Energy Cost: $86.40 5 Year Energy Cost: $432.00 5 Year Savings: $26,842.75 |

| Savings & Payback | Single Fixture Annual Savings: $74.56 72 Fixture Annual Savings: $5369 ROI Timeline: Under 19 months |

| Performance Summary | Energy Reduction: 46% 5-Year ROI: 22,648% Lamp Life: 50,000+ (LED) vs 30,000 (fluorescent) |

Case Study: Installation of new LED Lighting for Stone Basyx in Charlotte, NC

|

After: 150 Watt High Output UFO High Bay | 24000 Lumens |

|

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

Warehouse / Retail Lighting Installation Plan Metrics

- Mounting height: 23 ft

- Fixture Used: MLLG-LED-HBHO-150-5-120: 80 / 100 / 120 / 150 Watt Adjustable UFO High Bay | 16000 to 30000 Lumens | 5000K | 100-277V | High Performance

- FC achieved: 65.36 FC average

- Uniformity (Avg/Min): 2.21

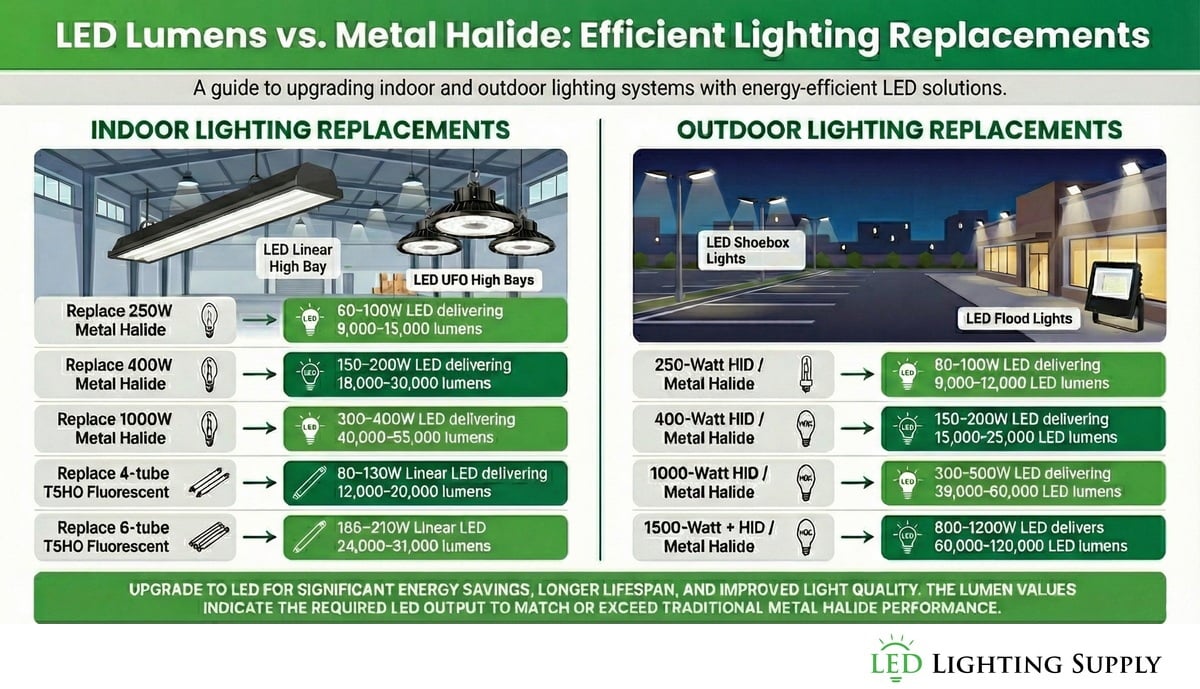

Matching LED Solutions to Your Needs: Replacing Legacy Lighting

LED Lighting Supply's expertise ensures proper illumination through documented installation results and professional lighting designs delivered across diverse warehouse environments.

What are the Cost Savings and ROI When You Convert from Metal Halide to LED?

165W LED Linear High Bay vs 400W Metal Halide Replacement (with ballast)

Assumptions: Based on 24 hours/day, 200 days/year at $0.20/kWh,

50 fixture(s), and a 15% ballast factor applied to the metal halide wattage

(400W lamp + 15% ballast = ~ 460W input).

•

Energy cost and ROI calculations are based on energy savings only and assume an LED fixture cost of

$155.00 per fixture.

• Maintenance savings from reduced bulb and ballast replacements are not included

in these calculations.

| Metal Halide (460W per fixture) |

Annual Energy Cost (per fixture): $441.60 Annual Energy Cost (all 50 fixtures): $22,080.00 5 Year Energy Cost (all fixtures): $110,400.00 5 Year Savings (all fixtures): $0.00 |

| LED Linear High Bay (165W per fixture) |

Annual Energy Cost (per fixture): $158.40 Annual Energy Cost (all 50 fixtures): $7,920.00 5 Year Energy Cost (all fixtures): $39,600.00 5 Year Savings (all fixtures): $70,800.00 |

| Savings & Payback |

Single Fixture Annual Savings (energy only): $283.20 50 Fixture Annual Savings (energy only): $14,160.00 LED Fixture Project Cost (50 fixtures): $7,750.00 Simple Payback from Energy Savings Only: under 7 months |

| Performance Summary |

Energy Reduction: 64% 5-Year ROI (All Fixtures, Energy Only): 814% Lamp Life: 50,000+ (LED) vs 15,000 (MH) |

In this example with 50 fixture(s), total LED fixture investment is approximately $7,750.00, and estimated annual energy-only savings are $14,160.00. Simple payback based on energy savings alone is under 7 months. Maintenance savings from eliminating metal halide bulb and ballast replacements provide additional value throughout the fixture's 50,000-hour lifespan, but are not included in this ROI calculation.

UFO vs. Linear High Bays: Strategic Selection for Optimal Results

UFO LED high bays are perfect for metal halide replacement, and LED linear high bays are your choice to replace fluorescent lighting.

| UFO High Bay Lights Engineered for Metal Halide Replacement & Open Space Illumination |

|

| Linear High Bay Lights Designed for Fluorescent Replacement & Aisle Illumination |

|

Quick Selection Guide

- UFO High Bays: Use for ceiling heights 20-65 ft and open warehouse areas; compact design ideal for replacing metal halide fixtures

- Linear High Bays: Use for ceiling heights 15-40 ft and structured racking layouts; superior aisle coverage and fluorescent replacement

- Foot-candle targeting: Plan for 10-20 FC in general storage, 30-50 FC in picking zones, 50-75 FC for inspection areas

- Wattage selection: Choose field-adjustable models (100/150/200W or 200/250/300W) to optimize performance after installation

- Motion sensors: Install only in storage areas with predictable occupancy; avoid high-traffic shipping zones and main aisles

- Professional calculation required: Use 20-30 lumens per sq ft for standard operations, 40-50 for high-activity areas; verify with photometric plan

Tip: Don't buy fixtures based on wattage replacement alone - calculate actual lumen requirements using foot-candle levels for each warehouse zone rather than assuming direct watt-to-watt replacement.

Professional Lumen Calculation Methods: Industry-Standard Illumination Planning

Our Product Specialists understand optimal lighting requirements through ANSI and IESNA standards, combined with photometric modeling techniques refined through thousands of successful installations.

Professional Foot-Candle Guidelines for Warehouse Operations

| General warehouse storage areas | 10-20 foot-candles |

| Active picking and packing zones | 30-50 foot-candles |

| Quality inspection and control areas | 50-75 foot-candles |

| Loading dock operations | 20-30 foot-candles |

| Warehouse aisle navigation | 15-25 foot-candles |

Professional Calculation Formula: Required Lumens = (Target FC x Square Footage) / Light Loss Factor (0.7-0.8)

Use Our Professional Indoor Fixture Count Lighting Calculator

Professional Warehouse Lighting Design Process: Determining Optimal Fixture Requirements

LED Lighting Supply's Professional Calculation Methodology

Comprehensive Space Analysis: We measure total square footage, ceiling height variations, and identify distinct lighting zones throughout your facility.

Operational Assessment: Our Product Specialists determine foot-candle requirements for storage areas versus active work zones.

Photometric Calculation: We utilize professional lighting software, including AGI32, for precise fixture placement, average foot-candle determination, and lighting uniformity analysis.

Professional Guidelines for Initial Planning

- Standard warehouse operations typically require: 20-30 lumens per square foot

- High-activity operational areas typically require: 40-50 lumens per square foot

- Professional spacing varies by ceiling height: 12-35 feet on center (subject to site conditions)

Professional Service: LED Lighting Supply provides complimentary lighting plans for all warehouse projects. With over 15 years of experience creating thousands of lighting plans, we provide detailed photometric analysis so you can evaluate lighting performance before making your investment.

How LED Lighting Supply Guides You to the Perfect Warehouse High Bay Solution

Our Product Specialists understand that every warehouse faces unique challenges. Drawing from thousands of successful installations, we prioritize four essential factors that determine project success:

- Ceiling Height Analysis: Determines optimal fixture type, mounting height, and spacing patterns to achieve uniform illumination

- Required Foot-Candle Levels: Assessment of lighting needs for each area, typically ranging from 10-50 FC, depending on tasks and safety requirements (when properly specified)

- Fixture Selection: Recommendation between UFO high bay and Linear high bay configurations based on ceiling height, layout, and operational environment

- Advanced Operational Requirements: Evaluation of motion sensors, dimming compatibility, and emergency backup systems to enhance efficiency and safety (subject to site conditions)

The Illuminating Engineering Society establishes comprehensive guidelines for warehouse and industrial lighting applications. IES standards and recommended practices for industrial lighting provide detailed specifications for illuminance levels, uniformity ratios, and quality metrics that ensure safe and productive warehouse operations across different task areas and ceiling heights.

Advanced Features That Maximize Warehouse Operational Efficiency

Modern commercial-grade lighting fixtures deliver performance advantages beyond basic illumination. LED Lighting Supply's expertise ensures you benefit from these operational efficiency features.

Professional-Grade Voltage and Adjustable Performance Features

- Voltage Compatibility:

- 120-277V standard commercial systems with automatic driver adjustment

- 277-480V industrial compatibility for single-phase and three-phase systems (depending on model)

- Advanced constant-current drivers with power factor >0.95

- Field-Adjustable Wattage Systems:

- Toggle-switch technology enabling on-site wattage optimization without fixture replacement

- Common ranges: 100W / 150W / 200W and 200W / 250W / 300W (verify on spec sheet)

- Color Temperature Selection:

- 3000K Warm White - Recommended for retail and customer-facing warehouse areas

- 4000K Neutral White - Standard commercial and fluorescent replacement

- 5000K Bright White - Industrial, MH replacement, precision work

- Optional CCT-toggle switches for post-installation color adjustment (depending on model)

- Beam Angle Adjustment (UFO Models):

- Rotating lens system enabling 60 deg / 90 deg / 120 deg optical adjustments

- Optimizes distribution for mounting height and fixture spacing needs

These adjustable high bay light fixtures deliver versatility for warehouse installations, featuring both wattage and color temperature adjustment capabilities.

Smart Control Integration for Enhanced Warehouse Efficiency

- Advanced Motion Sensor Technology:

- PIR Sensors are recommended for open warehouses and wide-area detection

- Microwave Sensors engineered for dusty, obstructed, or high-activity environments

- Professional detection range: 15-25 feet (model dependent)

- Dimming compatibility: 0-10V or 1-10V with 10%-100% brightness modulation

- Emergency Battery Backup Systems:

- Available in integrated or external battery pack configurations

- Supports 90-minute runtime emergency lighting requirements

- Emergency power output options from 10W-40W (verify on spec sheet)

- Fully OSHA-compliant for industrial egress lighting when properly specified

Professional Insight: Motion sensors deliver strong performance with LED technology. You can program dimmed operational levels during unoccupied periods or complete shutoff. LED technology doesn't degrade from frequent cycling, unlike traditional lights. Maximum energy savings typically result from fixtures operating at shutoff or dimmed to 10% capacity during inactive periods.

Professional Light Quality and Distribution Standards

- Color Rendering Index (CRI): 70+ standard performance for general warehouse operations

- Flicker-Free Operation: Eliminates visual fatigue for comfortable work environments with no humming from outdated ballast systems

- Instant Performance: 100% light output immediately, compared to 15-minute warm-up requirements for metal halide systems

- Cold Weather Performance: Maintains full brightness in cold storage environments, unlike fluorescent systems requiring warm-up periods

Professional Insight: 70 CRI provides adequate color rendering for standard warehouse operations. Higher CRI ratings become necessary for detailed inspection work or processes requiring precise color recognition.

Professional Mounting and Installation Options

UFO High Bay Mounting

- Eye Hook Configuration: Quick installation with adjustable cable systems

- Pendant Mount Systems: Rigid stem mounting for stable long-term installations

Linear High Bay Mounting

- Chain and Wire Suspension: Standard mounting for most warehouse applications

- Pendant Mount Systems: Rigid mounting for stable operational installations

- Surface Mount Options: Direct ceiling attachment where clearance is critical

This Rhode Island warehouse facility upgraded with our 200 Watt UFO fixtures, achieving energy savings exceeding 50% compared to their previous metal halide system.

Industrial-Grade Environmental Durability for Demanding Warehouse Conditions

- IP Ratings for Moisture Protection (UFO Models Only):

- IP65: Dust-tight with water-jet resistance for standard warehouse applications

- IP66: Dust-tight with powerful water-jet resistance for wash-down warehouse zones

- IP69K: High-pressure, high-temperature wash resistance for food distribution centers

- IK Impact Resistance Ratings (UFO Models Only):

- IK08: Rated for 5 Joules of impact resistance - recommended for standard warehouse conditions

- IK10: Rated for 20 Joules of impact resistance - engineered for heavy-duty industrial environments

Professional Recommendation: Facilities requiring moisture protection or high impact resistance achieve optimal results with UFO fixture configurations.

Professional Certifications and Industry Compliance Standards

| UL / ETL Listed | Electrical safety compliance for commercial and industrial facilities |

| DLC Certified | Qualifies fixtures for utility rebate programs |

| FCC Compliant | Meets electromagnetic interference prevention standards |

| RoHS Compliant | Meets environmental safety and restricted materials requirements |

The DesignLights Consortium establishes rigorous energy efficiency standards for commercial and industrial LED lighting systems. DLC qualification requirements ensure high-performance LED products meet strict efficacy and quality criteria, enabling utility rebate program participation while guaranteeing long-term energy savings performance. Additionally, UL safety certification provides comprehensive electrical safety testing and compliance verification for commercial lighting installations, ensuring proper operation in demanding warehouse environments.

Comprehensive Warranty Support and Professional Service

LED Lighting Supply provides a 5-year warranty on all warehouse high bay systems, with warranty support managed by our USA-based team. Our Product Specialists understand the importance of maintaining operational lighting systems and work efficiently to resolve any warranty concerns.

Professional Commitment: We handle all warranty claims directly through our experienced support team. You work directly with LED Lighting Supply throughout the entire warranty process, not third-party service providers.

Why LED Lighting Supply Delivers Superior Warehouse High Bay Lighting Solutions

Proven Warehouse Lighting Expertise and Customer Success

- 15+ Years: Dedicated commercial and industrial high bay lighting specialization

- 5,000+ Successful Installations: Documented performance across diverse commercial and industrial applications

- Exceptional Customer Satisfaction: Proven track record across all project types with outstanding customer reviews

- Professional Lighting Engineers: Our certified lighting design team provides complimentary photometric reports for every warehouse project

Ready to transform your warehouse lighting operations with professional industrial lighting solutions?

Request a quote from our warehouse lighting specialists for a complimentary consultation and professional photometric design. Our certified lighting engineers will create a custom solution that maximizes energy savings, improves operational safety, and delivers measurable ROI for your warehouse facility.

Important: Final lighting design and installation must comply with local building and electrical codes, OSHA requirements, and any applicable safety regulations. All electrical work should be performed by qualified, licensed professionals.

Common Mistakes and How to Avoid Them

After years of working with facility managers and contractors on warehouse conversions, we consistently see the same critical errors that compromise lighting performance and waste budget. Most of these mistakes come from not understanding how LED technology differs from the HID systems they're replacing.

- Installing fixtures on existing ceiling grid layouts without considering optimal photometric spacing. Use professional lighting calculations to determine proper spacing intervals based on mounting height and beam angles rather than matching old fixture locations.

- Selecting narrow beam angles for high ceilings without accounting for adequate aisle coverage between racks. Choose fixtures with adjustable optics or specify appropriate beam distributions for your specific ceiling height and layout requirements.

- Mixing different color temperatures throughout the same facility creates inconsistent lighting appearance and worker complaints. Specify consistent CCT across the entire warehouse unless specific work areas require different color temperatures for safety or quality inspection purposes.

- Ordering emergency battery backup on fixtures where it's not required by code adds unnecessary cost. Emergency lighting requirements only apply to egress paths and exit routes, not general warehouse storage areas.

LED Lights for Commercial Warehouses Frequently Asked Questions

What are LED warehouse lights and how do they differ from traditional lighting?

LED warehouse lights are high-output fixtures, including UFO and linear high bays, mounted at heights from 15 to 65 feet. Unlike metal halide or fluorescent systems, they provide instant-on performance and 50-75% energy savings without warm-up delays.

What types of LED warehouse lights are available?

UFO high bays are compact, circular fixtures with power ranges from 60W-600W and output up to 96,000 lumens, featuring IP65+ and IK-rated durability. Linear high bays offer extended rectangular format with power ranges from 80W-500W and output up to 76,900 lumens for superior aisle coverage.

How do I choose between UFO and linear high bay lights?

UFO high bays are recommended for ceiling heights 20 to 65 feet and open warehouse areas, ideal for metal halide replacement. Linear high bays are best for ceiling heights 15 to 40 feet with structured racking layouts and fluorescent replacement.

What ceiling heights are appropriate for LED warehouse lights?

LED warehouse high bays are engineered for ceiling heights ranging 15-65 feet where proper fixture spacing and beam angles can be calculated. Ceiling height below 15 feet creates glare and over-illumination from high bay fixtures.

How many lumens do I need for warehouse lighting?

Standard warehouse operations require 20-30 lumens per square foot, while high-activity operational areas require 40-50 lumens per square foot. Verify requirements with a photometric plan.

What are the recommended foot-candle levels for different warehouse zones?

General storage areas need 10-20 FC, active picking and packing zones need 30-50 FC, and quality inspection areas need 50-75 FC. Loading dock operations require 20-30 FC and aisle navigation requires 15-25 FC.

What wattage LED replaces a 400W metal halide fixture?

Replacement wattage depends on ceiling height, spacing, and required foot-candle levels for each zone. Do not buy fixtures based on wattage replacement alone - calculate actual lumen requirements using foot-candle levels rather than assuming direct watt-to-watt replacement.

Are LED warehouse lights dimmable?

LED warehouse lights offer dimming compatibility with 0-10V or 1-10V systems providing 10%-100% brightness modulation. Motion sensors can program dimmed operational levels during unoccupied periods or complete shutoff capabilities.

Can LED warehouse lights be used with motion sensors?

PIR sensors are recommended for open warehouses and wide-area detection, while microwave sensors are engineered for dusty, obstructed, or high-activity environments. Install motion sensors only in storage areas with predictable occupancy - avoid high-traffic shipping zones and main aisles.

What color temperature is best for warehouse lighting?

5000K is specified for industrial, metal halide replacement, and precision work. 4000K is standard for commercial and fluorescent replacement, while 3000K is recommended for retail and customer-facing warehouse areas.

What IP ratings are available for warehouse environments?

UFO models offer IP65 for standard warehouse applications, IP66 for wash-down warehouse zones, and IP69K for high-pressure, high-temperature wash resistance in food distribution centers. IP ratings apply to UFO models only.

Do LED warehouse lights work in cold storage facilities?

LED warehouse lights maintain full brightness in cold storage environments, unlike fluorescent systems requiring warm-up periods. Verify operating range specifications on the datasheet for your specific temperature conditions.

What certifications should I look for in warehouse LED lights?

Look for UL or ETL Listed for electrical safety compliance, DLC Certified to qualify for utility rebate programs, FCC Compliant for electromagnetic interference prevention, and RoHS Compliant for environmental safety requirements.

How long do LED warehouse lights last?

LED Lighting Supply provides comprehensive 5-year warranty coverage on all warehouse high bay systems. LED technology does not degrade from frequent cycling, unlike traditional lights.

What is the warranty on your LED warehouse lights?

All warehouse high bay systems include 5-year warranty coverage with complete warranty support managed by a USA-based team. Warranty claims are handled directly through LED Lighting Supply, not third-party service providers.

How are LED warehouse lights mounted?

UFO high bays use eye hook configuration with adjustable cable systems or pendant mount systems for rigid stem mounting. Linear high bays offer chain and wire suspension, pendant mount systems, or surface mount options for direct ceiling attachment.

Can I get a lighting plan for my warehouse?

LED Lighting Supply provides complimentary lighting plans using professional AGI32 software for photometric analysis. Plans include precise fixture placement with spacing calculations, average foot-candle levels, and uniformity ratios.

What information do I need to request a warehouse lighting quote?

Provide ceiling height and mounting constraints, required foot-candle levels by zone, existing electrical voltage (120-277V or 277-480V), environmental conditions, and control requirements such as motion sensors, dimming, or emergency backup.

Do you offer emergency backup options for warehouse lights?

Emergency battery backup systems are available in integrated or external battery pack configurations supporting 90-minute runtime requirements with emergency power output options from 10W-40W. Emergency lighting requirements only apply to egress paths and exit routes, not general warehouse storage areas.

Are LED warehouse lights eligible for utility rebates?

DLC Certified fixtures qualify for utility rebate programs. DLC qualification requirements ensure high-performance LED products meet strict efficacy and quality criteria for rebate program participation.

![Lls X Hb9 150a Cc [c]](https://www.ledlightingsupply.com/wp-content/uploads/2025/09/LLS-X-HB9-150A-CC-C-800x800.jpg)