Showing 1–12 of 24 results

- SKU:MLLG-LED-HT80-50-110-[V] | Web ID:1317100V-277V:105 In StockShips 2-3 Days277V-480V:Built to Order 6 Weeks

- Watts: 50

- Lumens: 6500

- Lumens/Watt: 130

- Replaces: 175 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 110°

- Beam Angle (Opt): 30° | 90° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 12.1 X 14.4 X 9.6 in

- Weight: 17.2 lbs

Starting At$439.60 - SKU:MLLG-LED-HT80-100-50-110-[V] | Web ID:1318100V-277V:166 In StockShips 2-3 Days277V-480V:Built to Order 6 Weeks

- Watts: 100

- Lumens: 13000

- Lumens/Watt: 130

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 110°

- Beam Angle (Opt): 30° | 90° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 12.1 X 14.4 X 9.6 in

- Weight: 17.2 lbs

Starting At$539.15 - SKU:MLLG-LED-HT80-150-50-110-[V] | Web ID:1319100V-277V:111 In StockShips 2-3 Days277V-480V:Built to Order 6 Weeks

- Watts: 150

- Lumens: 19500

- Lumens/Watt: 130

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 110°

- Beam Angle (Opt): 30° | 90° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 15.8 X 14.4 X 9.6 in

- Weight: 20.75 lbs

Starting At$649.29 - SKU:MLLG-LED-HT80-200-50-110-[V] | Web ID:1320100V-277V:58 In StockShips 2-3 Days277V-480V:Built to Order 6 Weeks

- Watts: 200

- Lumens: 26000

- Lumens/Watt: 130

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 110°

- Beam Angle (Opt): 30° | 90° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 19.5 X 14.4 X 9.6 in

- Weight: 26.20 lbs

Starting At$870.24 - SKU:MLLG-LED-HT80-300-50-90-[V] | Web ID:1321100V-277V:Built to Order 6 Weeks277V-480V:Built to Order 6 Weeks

- Watts: 300

- Lumens: 39000

- Lumens/Watt: 130

- Replaces: 1000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No | 1-10V

- Beam Angle (Std): 90°

- Beam Angle (Opt): 30° | 110° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 26.9 X 14.4 X 9.6 in

- Weight: 42.55 lbs

Starting At$1,305.20 - SKU:MLLG-LED-HT80-450-50-90-[V] | Web ID:1322100V-277V:Built to Order 8 Weeks277V-480V:Built to Order 8 Weeks

- Watts: 450

- Lumens: 58500

- Lumens/Watt: 130

- Replaces: 1000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 12kV

- Operating Temp: -40°F to 176°F

- Rated Life: 100,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 90°

- Beam Angle (Opt): 30° | 110° | 150°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Trunnion

- Dimensions: 38.0 X 14.4 X 9.6 in

- Weight: 61.7 lbs

Starting At$1,816.62 - SKU:MLLG-LS-LED-HB-40-[Color]-HT-[V] | Web ID:1735100V-277V:Built to Order 6 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 40

- Lumens: 6000

- Lumens/Watt: 150

- Replaces: 150 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 8.5 X 12 X 8.65 in

- Weight: 12 lbs

Starting At$542.91 - SKU:MLLG-LS-LED-HB-100-[Color]-HT-[V] | Web ID:1323100V-277V:Built to Order 6 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 100

- Lumens: 13000

- Lumens/Watt: 130

- Replaces: 250 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 12 X 12 X 8.65 in

- Weight: 13.2 lbs

Starting At$956.37 - SKU:MLLG-LS-LED-HB-150-[Color]-HT-[V] | Web ID:1324100V-277V:Built to Order 6 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 150

- Lumens: 19500

- Lumens/Watt: 130

- Replaces: 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 14.17 X 13.77 X 8.65 in

- Weight: 19 lbs

Starting At$1,442.00 - SKU:MLLG-LS-LED-HB-200-[Color]-HT-[V] | Web ID:1325100V-277V:Built to Order 6 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 200

- Lumens: 26000

- Lumens/Watt: 130

- Replaces: 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 18.11 X 14.17 X 8.65 in

- Weight: 24.6 lbs

Starting At$1,959.92 - SKU:MLLG-LS-LED-HB-300-[Color]-HT-[V] | Web ID:1326100V-277V:Built to Order 8 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 300

- Lumens: 39000

- Lumens/Watt: 130

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 19.6 X 16.53 X 8.65 in

- Weight: 38.3 lbs

Starting At$2,837.92 - SKU:MLLG-LS-LED-HB-400-[Color]-HT-[V] | Web ID:1327100V-277V:Built to Order 8 Weeks347V-480V:Built to Order 8 Weeks

- Watts: 400

- Lumens: 52000

- Lumens/Watt: 130

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- Voltage: 100V-277V | 347V-480V

- Operating Temp: -40°F to 194°F

- Rated Life: 70,000 hours

- Dimmable: No

- Beam Angle (Opt): 10° | 25° | 40° | 90° | 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Eye-Hook | Pendant

- Dimensions: 22 X 20.86 X 8.65 in

- Weight: 45.8 lbs

Starting At$3,662.64

What are LED Lights for a Power Plant?

Power plant facilities require specialized LED light fixtures that combine indoor LED lighting and outdoor LED lighting systems engineered for extreme conditions. Outdoor areas demand robust LED perimeter security lighting alongside general illumination, with LED parking lot lights providing reliable coverage across expansive parking zones.

Indoor environments present unique challenges, especially in steam generation areas where high temperature LED lights must withstand ambient conditions reaching 392°F. Our specialized fixtures handle these harsh environments while maintaining optimal performance and generating minimal heat. Standard areas benefit from our general-purpose industrial LED lighting solutions that deliver significant energy savings, typically reducing consumption by 50 to 75% compared to traditional systems.

The U.S. Department of Energy recognizes LED technology as the most energy-efficient lighting solution for industrial facilities, often delivering energy savings of 50% or more compared to conventional lighting systems. Their comprehensive LED lighting guidance emphasizes the operational cost reductions and improved performance that make LEDs valuable in demanding industrial applications like power generation facilities.

All fixtures feature durable aluminum construction - no steel or iron components that could corrode in power plant environments. When selecting LED power generation lighting, we focus on three critical performance categories:

- Environmental protection with high impact ratings (IK08+) and wet location certification (IP65+)

- High-temperature capability for fixtures operating in ambient temperatures up to 392°F, model dependent

- LED explosion proof lights with hazardous location compliance with UL844 certifications

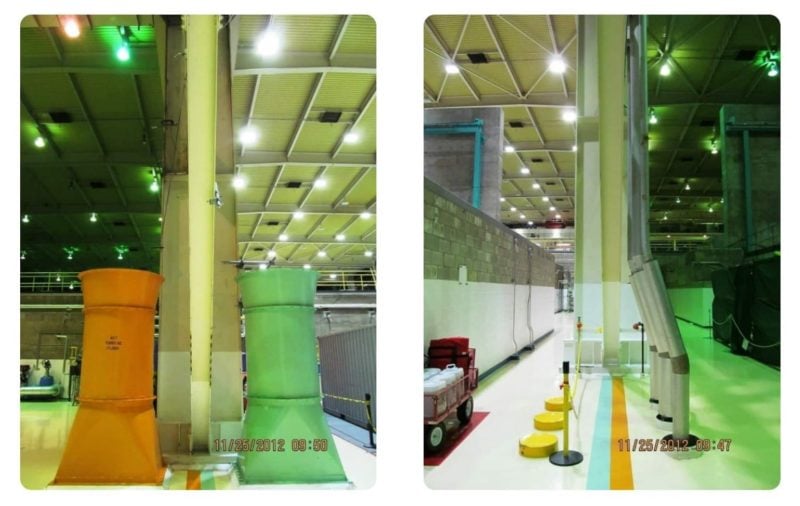

We have supplied radiation-tolerant LED fixtures that have undergone rigorous EMC testing for nuclear facilities nationwide. Many installations include refueling floor applications directly above reactors where extreme heat and radiation exposure occur continuously. These mission-critical fixtures provide 24/7 operation in the most demanding power generation environments. Drawing from over 15 years of power plant lighting experience, our specialists recommend solutions tailored to your facility's specific operational requirements.

Our fixtures illuminate a nuclear facility in Alabama, where bright white LED lighting replaced the legacy mercury vapor systems shown in green.

What are Nuclear Grade LED Lighting Systems?

Nuclear-grade LED systems represent the highest tier of industrial lighting, engineered to exceed the rigorous safety, reliability, and durability standards mandated for nuclear power plant operations.

Key Features of LED Lighting Supply Nuclear Grade LED Lighting Systems

- Radiation Resistance - Components maintain performance integrity under continuous radiation exposure without material degradation.

- Seismic and Impact Resistance - Robust construction withstands vibrations, mechanical shocks, and seismic events inherent to nuclear facility operations.

- High Temperature Performance - Specialized models operate reliably in extreme heat environments with ratings up to 392°F, model dependent.

- Extended Service Life - Nuclear-grade fixtures deliver 50,000+ hours of maintenance-free operation, minimizing costly shutdowns.

- EMC Compliance - Rigorously tested to prevent electromagnetic interference with sensitive nuclear monitoring and control systems.

- Explosion-Proof & Environmental Ratings - Available with hazardous-location certifications when properly specified and IP65 wet-location protection for demanding environments.

Nuclear facilities must comply with stringent safety and performance standards established by regulatory authorities. The Nuclear Regulatory Commission provides comprehensive guidance on equipment qualification requirements, including lighting systems that must demonstrate reliable performance under extreme conditions. These federal safety regulations mandate rigorous testing protocols for all components operating in nuclear environments to ensure continuous safe operation.

High-output bay fixtures provide superior illumination throughout this Michigan nuclear facility's critical operational areas.

Applications of Nuclear Grade LED Lighting

- Reactor containment areas

- Turbine halls and generator rooms

- Control rooms and monitoring stations

- Emergency egress and safety lighting

- Spent fuel storage facilities

- Decontamination chambers

- Security perimeters and checkpoints

What are the Benefits of LED Lights in a Power Plant / Nuclear Power Facility?

- Superior Light Quality - Advanced LED technology produces consistent, flicker-free illumination that enhances visibility for precision maintenance work and accurate control panel readings during extended operations.

- Extended Operational Life - Fixtures deliver 50,000+ hours of reliable service, reducing maintenance shutdowns and eliminating dangerous bulb replacement procedures in radioactive zones.

- Extreme Temperature Capability - Purpose-built fixtures maintain peak performance in ambient conditions reaching 302°F, engineered for steam generation environments where conventional lighting fails rapidly.

- Substantial Energy Reduction - Facilities typically achieve 50-75% lower electricity consumption versus legacy metal halide or fluorescent installations, with additional savings through integrated occupancy sensing.

- Smart Controls Integration - Compatible with motion sensors and facility management systems, enabling automatic full-brightness response when personnel enter work areas while maintaining energy efficiency when unoccupied.

- Zero Hazardous Materials - Mercury-free construction eliminates special disposal requirements and reduces environmental compliance costs associated with fluorescent tube replacement programs.

- Enhanced Safety Performance - Uniform, high-output illumination minimizes accident risk in critical operational zones while maintaining consistent brightness throughout the fixture's life.

- Immediate Full Output - Instant-on capability provides 100% brightness without warm-up delays, ensuring optimal visibility during emergency procedures and scheduled maintenance activities.

Safety and Performance Certifications

Our fixtures carry essential certifications, including DLC Premium for energy efficiency and rebate eligibility, UL Listed for electrical safety, and ETL Listed for product safety compliance. These certifications ensure safety, performance, and energy efficiency while qualifying your project for utility rebates and tax incentives. DLC Premium certification guarantees the highest efficiency standards and maximum rebate eligibility.

5-Year Warranty and Support

All our lights come with at least a 5-year warranty, and all warranty support is based in the USA. We take customer support seriously and will work quickly to resolve any warranty issues. Our experienced support team understands the importance of keeping your lighting operational.

Expert Support for Your Power Plant Lighting Project

Our power plant lighting specialists provide comprehensive support to ensure your facility receives optimal illumination solutions. We create custom lighting plans that calculate exact fixture placement and performance specifications for your unique facility layout. Our engineering team performs detailed energy savings calculations showing your projected annual and long-term cost reductions with specific ROI timelines.

With over 15 years of commercial lighting experience, our product specialists understand the critical operational challenges your facility faces. They provide expert guidance on fixture selection based on your specific environmental conditions, safety requirements, and maintenance constraints. This expertise ensures you receive lighting solutions that meet the demanding performance standards required for reliable power generation operations. These solutions can be integrated throughout your entire building.

Common Mistakes and How to Avoid Them

Power generation facilities present some of the harshest environments for lighting equipment. I've watched plenty of retrofits fail because someone didn't account for the real conditions these fixtures face daily.

- Installing standard industrial fixtures in steam areas where you need 392°F capability. Standard LED drivers fail fast in high heat zones, so spec fixtures are designed for those conditions from the start.

- Overlooking EMC testing requirements for nuclear plants. Control room interference from poorly shielded fixtures can shut down operations and cost millions in downtime.

- Using fixtures with steel components that corrode within months in power plant atmospheres. Aluminum construction costs more upfront but saves replacement headaches later.

- Underestimating seismic requirements and vibration resistance. Turbine areas shake constantly, and fixtures without proper mounting fail at connections.

- Selecting inadequate IP ratings for condensation and washdown areas. IP54 isn't enough when you have steam and cleaning protocols that require IP65 minimum.

- Ignoring radiation tolerance specs in reactor areas. Regular LED phosphors degrade under radiation exposure, and color shifts badly over time.

- Calculating light levels using office standards instead of maintenance task requirements. Precision work on generators needs 100+ foot candles, not 50.

LED Lighting for Power Generation Facilities Frequently Asked Questions

What are LED lights for a power plant?

Power plant LED fixtures include indoor and outdoor systems engineered for extreme conditions, including high temperature models rated up to 392°F for steam generation areas and explosion proof lights with UL844 certification for hazardous locations. All fixtures feature durable aluminum construction with no steel or iron components that could corrode in power plant environments.

What are nuclear grade LED lighting systems?

Nuclear-grade LED systems are engineered to exceed safety, reliability, and durability standards for nuclear power plant operations, featuring radiation resistance, seismic and impact resistance, and EMC compliance to prevent interference with sensitive monitoring and control systems. Specialized models operate reliably in extreme heat environments with ratings up to 302°F, model dependent.

What are the benefits of LED lights in a power plant or nuclear power facility?

LED fixtures deliver 50,000+ hours of reliable service, reducing maintenance shutdowns in radioactive zones, while achieving 50-75% lower electricity consumption versus legacy metal halide or fluorescent installations. Mercury-free construction eliminates special disposal requirements, and instant-on capability provides 100% brightness without warm-up delays during emergency procedures.

What safety and performance certifications do power plant LED fixtures carry?

Fixtures carry DLC Premium, UL Listed, and ETL Listed approvals, along with IP65 wet-location protection and IK08+ impact ratings. DLC Premium certification qualifies projects for utility rebates and tax incentives.

What warranty coverage is provided for power plant LED lighting?

All fixtures include at least a 5-year warranty with USA-based support.

What are common mistakes when selecting power plant LED lighting?

Common errors include installing standard fixtures in steam areas requiring 302°F capability, overlooking EMC testing requirements for nuclear plants where control room interference can shut down operations, and using fixtures with steel components that corrode in power plant atmospheres. Selecting inadequate IP ratings is also problematic - IP65 minimum is required for condensation and washdown areas.

![Mllg Led Ht80 100 50 110 [3]](https://www.ledlightingsupply.com/wp-content/uploads/2019/05/MLLG-LED-HT80-100-50-110-3-800x800.jpg)