LED Lighting Supply Blog

Welcome to LED Lighting Supply Blog. We tried to put together a collection of posts related to LED Education, Electrical Contractor Resources, and just good information related to topics similar to LED Lighting. So whether you are looking for information on Buyers Guides to High Bays or Parking Lot Fixtures, information on lumens, color temperature or color rendering index, or the path on how to become an electrician, our blog posts will hopefully help and educate you.

Correctional Facility LED Lighting: What to Consider for Every Indoor and Outdoor Area

Lighting in a prison or correctional facility is not a typical commercial project. Every fixture...

What to Consider When Installing LED Lighting for Pickleball and Padel Courts

Proper lighting is one of the most critical factors in the performance, safety, and long-term...

LED Sports Field Lighting Guide for Schools, Parks, and Community Facilities

This guide is written for schools, park districts, municipalities, and community sports facilities...

LED Vapor Proof Lights vs NSF Certified Lights: Differences, Similarities, and How to Choose the Right One

Choosing the correct lighting for harsh or regulated environments is not just about brightness or...

Best Applications for HVLS Fans in Commercial and Industrial Facilities

High-volume, low-speed (HVLS) fans are no longer viewed as optional comfort accessories in large...

When to Use Vapor Proof Lights vs. Explosion Proof Lights (C1D1 / C1D2)

If you work in manufacturing, food processing, cold storage, wastewater, or chemical handling,...

The Buyers Guide to Outdoor Security Lighting (Commercial & Industrial)

Outdoor security lighting does more than "make things brighter." When it's selected and positioned...

Choosing the Right High Bay Fixture for a Gymnasium or Fitness Center

When you’re planning lighting for a school gym, athletic court, or a fitness facility, the...

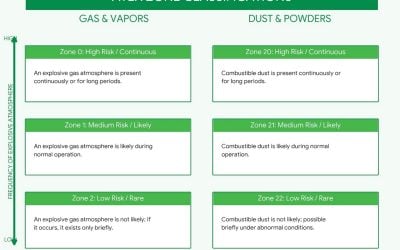

ATEX Lighting Guide: Understanding Hazardous Location Zones vs Divisions

ATEX and IECEx classifications are frequently misunderstood by North American engineers,...

Hazardous Location Lighting Classifications Explained: Class I vs Class II, Division 1 vs Division 2, and Groups

Explosion-proof and hazardous location lighting is a code-driven safety decision. In North...

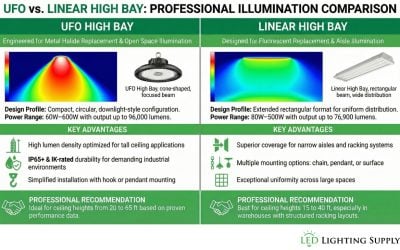

UFO vs Linear High Bay Lights: How to Choose the Right Fixture for Your Facility

Electricians and facility managers typically choose between UFO high bays and linear high bays for...

Why LED Conversion Makes More Financial Sense in 2026 Than It Did in 2010

LED Lighting Supply has completed over 25,000 commercial lighting projects since 2010, helping...

What Is the Difference Between Wood Pilings and Composite Pilings?

Match Point Pickleball Club Announces Strategic Lighting Partnership With LED Lighting Supply

Completed Project Photos

Green Business Podcast

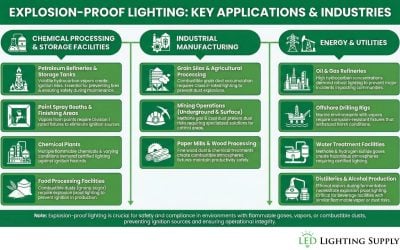

An Expert Q and A with CEO Neil Peterson: The Importance of Explosion Proof Lights In Industrial Facilities

In a recent interview, our Digital Marketing Manager sat with Neil Peterson, CEO of LED Lighting...

Disaster Recovery Following Hurricane Maria

From September 19 to 21, 2017, Hurricane Maria impacted Puerto Rico as a major hurricane, causing...

The Complete Guide to Wood Pole Standards

Utility poles form the backbone of our electrical and telecommunications infrastructure, carrying...

Incorporating Bollard Lights into Your Landscape

Bollard lights enhance landscape appeal while providing functional illumination for pathways,...

How to Enhance Real Estate Investments with LED Lighting

When it comes to selling properties, lighting makes a huge difference. Whether it's residential or...

Commercial Ceiling Fans Buyers Guide

Since 2000, the average cost of electricity in the United States has more than doubled. For...

HVLS Fans: A Comprehensive Buyers Guide

High temperatures, humidity, and inadequate ventilation present significant challenges for...

Buyers Guide to Composite Fiberglass Poles

Light and utility poles face extreme weather conditions, mechanical stress, and environmental...

Steel Distribution Pole Maintenance: A Complete Guide

Important Safety Notice: All electrical work and utility pole inspections must be performed by...

Comparing Utility Wood Pole Treatments: CCA vs DCOI vs PENTA

Wood poles serve as the backbone of our electrical infrastructure, requiring specialized...

Buyers Guide to Light Poles: How to Choose the Right Height, Material, and Design

Light poles serve as the backbone of effective outdoor illumination systems, supporting fixtures...

How Much Amp Load Can You Reduce by Replacing Metal Halide with LED?

Quick Answer: Replacing metal halide lighting with LED typically reduces amperage draw by 65-75%....

2700K vs 3000K vs 4000K vs 5000K vs 6500K: Best Color Temperature For Your Space

When lighting your commercial, industrial, or sports space, the choice of color temperature is not...

Lighting Consumer: Watts, Lumens, or Foot Candles – Which is Most Important?

When selecting LED lighting for your facility, three fundamental measurements drive performance...

Best Practices for Electrical Contractors Installing Warehouse Lighting

Warehouse lighting projects present unique challenges for electrical contractors, including...

Tunable LED Lighting Guide: Wattage, Color Temperature & Applications

LED lighting technology has evolved dramatically over the past decade, bringing unprecedented...

Who Actually Invented the Lightbulb: The History of Modern Lighting

LED Lighting Supply explores the fascinating evolution of electric lighting technology, from early...

Lighting Codes and Standards: A Comprehensive Guide

State and local governments establish building codes as regulations for buildings and other...

EPA Wind Rating Map: Everything You Need to Know

High-powered flood lights and LED area lights are essential fixtures for illuminating outdoor...

How LEDs Pay for Themselves

One of the most common hurdles for large lighting projects is securing adequate funding. Sports...

Light Pole Components: A Comprehensive Guide

Light poles are essential infrastructure found in virtually every outdoor lighting application....

The Complete Guide to Light Pole Installation

Street and parking lot lights deliver powerful illumination across extensive outdoor areas where...

Light Pole Maintenance: The Complete Guide

Important: This guide provides general information only. For structural assessments, safety...

How to Replace 1500 Watt and 2000 Watt Metal Halide Fixtures with LED

What Does it Take to Replace 1500 Watt and 2000 Watt Metal Halide with LED?Quick Answer: A...

Microwave vs PIR Motion Sensors: Which is Better?

Lighting controls extend beyond basic dimmers and timers to include sophisticated sensor...

How to Reduce Heat from LED Lights

LED lighting has gained widespread adoption due to its energy efficiency, extended lifespan, and...

The Complete Guide to How LED Lights are Made

LED lights are currently among the most energy-efficient lighting systems available. Many...

Tax Credits for LED Lights: The 179D Tax Deduction

Tax Disclaimer: This content is for general informational purposes only and should not be...

LED Lighting Upgrades for Facility Managers

As a facility manager, you're responsible for all aspects of the physical infrastructure of an...

Maintained vs Non-maintained Emergency Lights: Explained

Whether it's a power outage, fire, or natural disaster, people in any facility need properly...

The History of LED Lights

As a leading LED lighting supplier, we've seen firsthand how LED technology has transformed the...

LED Binning: Guaranteeing Lighting Standards

LED binning is a quality control process that sorts LED chips by color temperature and brightness...

The Difference Between Clear vs Frosted LED Bulbs

Important: LED fixture installation should be performed by qualified electricians in accordance...

LED Lighting Environmental Impact: 10 Ways LEDs Help the Planet

LED lighting technology has transformed how businesses and facilities approach energy efficiency...

ESG: Enhancing Your Company’s Strategy with LED

What is ESG?ESG stands for "Environmental, Social, and Governance" - a framework that evaluates...

LED Lighting Statistics to Know in 2025

Note: The following statistics are compiled from various industry sources and represent general...

The Best Lighting Audit Software

A successful LED lighting retrofit doesn’t start with choosing fixtures-it starts with...

High Temperature LED Fixtures Engineering: The Science of Managing Heat in LED Lights

Electronic components face significant challenges when exposed to excessive heat, with standard...

Reduce Light Pollution: Top 9 Strategies

What is Light Pollution?We've all heard about different kinds of pollution-air pollution from...

Buyers Guide to LED Baseball and Softball Lighting

Buying Tips for Choosing the Perfect Baseball and Softball LightsBaseball and softball field...

How to Eliminate Lighting Shadows and Achieve Even Illumination with Commercial LED Lights

Lighting shadows, also called tunneling, occurs when uneven light distribution creates noticeably...

Case Study: FUPC of Dale City’s Parking Lot Retrofit Project Increased Efficiency & Reduced Maintenance

Understanding Watts, Volts, and Amps When It Comes to LED Lighting

Most electrical terminology is related in some way, and understanding the basics makes it easier...

Indoor Natatorium Case Study: Wayne’s Electric Service Upgrade

Indoor Gym Case Study: TBCS’s Gym Lighting Upgrade

LED Lighting Standards Testing and Certification: a Comprehensive Guide

Understanding lighting standards, testing, and certifications is essential for making informed...

Nema Beam Spread: Understanding Lighting Distribution

Understanding NEMA Lighting ClassificationsNEMA (National Electrical Manufacturers Association)...

Lighting Certifications Explained: What They Mean for Commercial & Industrial Projects

When you're planning a lighting upgrade, whether it's a warehouse, a high bay application, a...

Parking Lot Case Study: Healthy Living Technology Boosts LED Upgrades for Cost Reduction & Fixture Longevity

Buyer Beware – LED Purchases Gone Wrong

Throughout my 15+ years in commercial lighting, we've helped hundreds of customers resolve...

What is Dark Sky Compliance and Why it Matters

Dark sky compliance has emerged as a crucial standard in outdoor lighting, driven by the dark-sky...

Softball Case Study: Conyers Electrical Boosts Light Levels by 87%

Warehouse Lighting Upgrade Results in Energy Savings Improvement of 73%

Spartan Sports Park Case Study: 65% Energy Cost Savings & Enhanced Light Levels

Buyers Guide to Commercial LED Shop Lighting

Workshop environments demand precise, reliable lighting that supports both safety and...

Commercial LED Flood Lighting Buyers Guide: Selection, Optics, and Applications

Selecting and purchasing flood lights to illuminate outdoor areas can be a tricky endeavor. Why is...

Buyers Guide to LED Stadium and Sports Field Lighting

Helpful Tips Before Purchasing LED Sports Field LightingOutdoor athletic events draw massive...

Buyers Guide to LED Warehouse Lighting

Commercial and industrial warehouses across the nation are discovering substantial energy savings...

How to Choose LED High Bay Lights

Industrial and commercial facilities struggling with outdated metal halide and high-pressure...

LED Wall Pack Lights: A Practical Guide to Types, Controls, and Performance

LED wall pack lights serve as the backbone of commercial exterior lighting, transforming how...

Metal Halide to LED Conversion Guide: Retrofit Kits vs Full Fixture Replacement

Upgrading metal halide (MH) lighting to LED is one of the fastest ways to reduce energy use,...

Buyers Guide to LED Parking Lot Lights

Commercial property owners understand that proper parking lot illumination goes beyond basic...

Modern Electrician Podcast

Let There Be Photometrics: Podcast TranscriptNeil Peterson from LED Lighting Supply recently...

LED Canopy Lights for Replacing Metal Halide & HPS Fixtures

Looking to convert your existing metal halide or high-pressure sodium lighting to LED? Are you...

Damp Location Lighting vs Wet Location Lighting

When selecting lighting for commercial and industrial applications, you'll encounter fixtures...

LED Equivalent Chart

LED lighting is widely recognized for energy efficiency and cost savings in commercial and...

Buyers Guide to LED Low Bays

What are Low Bays?Low Bay fixtures serve as primary illumination for indoor commercial spaces with...

Guide to Exit Sign Requirements

LED Exit Signs and Emergency Lighting provide reliable illumination when you need it most while...

Design Guide for Lighting a Sports Field

From soccer fields and baseball fields to tennis courts and basketball courts, field and stadium...

Office Lighting Design Guide

Upgrade Your Office with LED LightingOffice lighting design involves more complexity than simply...

Food Processing LED Lighting Requirements: NSF Certification, IP Ratings, and Compliance

Everything in the food and beverage manufacturing industry must be tested and approved for safe...

LED Factory Lighting Buyers Guide: Standards, Foot Candles, and Fixture Selection

Manufacturing facilities, factories, and industrial spaces demand precision lighting solutions...

Buyers Guide to Commercial LED Natatorium Lighting

Navigating Swimming Pool LightingCommercial natatoriums and indoor swimming pools demand...

Title 20 Compliant Guide: California Lighting Regulations

The California Energy Commission (CEC) was established by the Warren-Alquist Act in 1974. At the...

What Is a Foot Candle and a Practical Guide to Lighting Levels by Application

What is a Foot Candle?A foot-candle measures light intensity, equivalent to one lumen of light per...

Guide to Industrial Lighting Design

Industrial facilities present unique lighting challenges that demand specialized solutions. From...

Hazardous Location Lighting Requirements for Explosive Environments

Lighting requirements in explosion-proof environments are governed by the National Electrical Code...

LED Vapor Proof Lighting: What It Is, Where to Use It, and How to Choose the Right Fixture

Vapor proof lights are luminaires that are shock-proof, waterproof, and dustproof. They come in...

Lighting Audit Checklist

If you're a facilities manager, you likely perform periodic checkups of the heavy machinery and...

Guide to Lighting in Airports

Airport lighting systems are critical infrastructure that enable safe 24/7 aviation operations....

LED Highway Lighting Guide

Highway Lighting: Safety and Visibility SolutionsHighway lighting plays a crucial role in ensuring...

Buyers Guide to LED Lights and Color Temperature

Although often overlooked, color temperature deserves careful consideration when installing new...

High Bays vs Low Bays: How to Choose the Best Option

Before we discuss the differences between LED high bays and low bays, it is essential to...

How to Convert Fluorescent to LED: 5 Cost Effective Ways

When fluorescent lighting first became available, it offered improved efficiency compared to...

Color Rendering Index (CRI) Explained

Things to Know About CRIUnderstanding Color Rendering Index (CRI) helps you choose LED lighting...

Why Upgrade to LED Lighting?

Modern technology has transformed efficiency across industries, from smartphones to fuel-efficient...

Converting Fluorescent Tube Light to LED – Upgrade Your Shop Lights

If you’re still using fluorescent fixtures in your facility or workshop, you’re not...

Buyers Guide to LED Street Lighting

LEDs Make Streets BrighterStreet lights serve a critical function in illuminating walkways,...

Metal Halide vs LED Lighting: Energy Savings, Efficiency, and Cost Comparison

Converting from Metal Halide Lamp (HID) lighting to LED lighting typically saves money on energy...

LED Lumens Explained: Understanding Brightness, Efficiency, and Light Quality

LED Lumens - There is No ComparisonLED lighting has become the dominant technology across...

Pitfalls of Buying LED: Avoid Bad Purchases

Many commercial and industrial facility owners are considering replacing their Metal Halide...

The Cost of Not Converting to LED Lights

Converting to LED delivers quantifiable returns that many facility managers underestimate. After...

250W Metal Halide LED Replacement

What Does it Take to Replace a 250-Watt Metal Halide?Too bright is as bad as too dim. Trying to...

LED Frequently Asked Questions

Commercial Indoor & Outdoor LED Lighting FAQsWhat is commercial LED lighting?Commercial LED...

LED vs Fluorescent Office Lighting

What's the Best Lighting for an Office Environment?Office lighting requires balancing multiple...

IK Impact Rating Chart for LED Light Fixtures

LED lights are commonly used in commercial lighting, industrial lighting, and sports lighting...

What is an LED? Complete Guide to LED Technology

LEDs, or Light-Emitting Diodes, are semiconductor electronic devices that produce visible light...

IP Rating and LED Light Fixtures

Shopping for LED commercial and industrial lighting can be confusing. There are many factors to...

Metal Halide Fixtures: Components, Applications, and LED Conversion Guide

A metal halide fixture is a commercial or industrial lighting system with five essential...

LED Lighting Tips: Color Temperature, Retrofits, Wattage, Rebates & More

We compiled a comprehensive collection of LED lighting insights based on 15+ years of commercial...

Lighting Guide for Education Institutions

Professional lighting design is critical for educational institutions, where proper illumination...

Selecting the Best LED Lighting for Different Types of Sports Venues

Many professional teams across major American sports leagues (NHL, NBA, MLB, and NFL) have...

LED Lighting Controls: Motion Sensors, Dimmers, and Smart Systems for Energy Savings

LED lighting technology paired with automated controls can significantly reduce energy consumption...

Replacing a 400 Watt Metal Halide with LED: Wattage, Lumens, and Real-World Savings

What Does it Take to Replace 400 Watts Metal Halide Bulb with LED?Converting from 400-watt metal...

LED Active Cooling vs Passive Cooling

LED lights achieve efficiency rates of up to 80% energy savings compared to traditional...

Lumens to Watts Conversion – Never Buy Based on Watts

This is a common message we try to impart to our customers when they call us. For example, it is...

Recycle Fluorescent Tubes: Proper Steps & Tips

You'll find tube lights in many applications, such as office buildings, hallways, garages, and...

LED Replacement for 1000W Metal Halide: Power Requirements and Specifications

A 1000-watt metal halide fixture typically requires a 300 to 400 watt LED replacement producing...

Lumen Depreciation and LED Lighting

When replacing lighting systems, the goal is to reduce operating costs while maintaining or...

Using S/P Ratios to Convert HPS and Metal Halide to LED

After 15+ years of helping customers convert from traditional lighting, one of the most common...

Do Dimmer Switches Save Power?

What is a Dimmer Switch?Dimmer switches allow you to adjust the light output of fixtures, giving...

How to Calculate Lumens Per Watt

LED Wattage for Replacing Existing LightingThis question comes up constantly in our lighting...

How To Read LED Light Specifications: Lumens, Watts, & Other Metrics Explained

Selecting the right LED lighting requires understanding key specifications that determine...

Lighting Maintenance Factor Explained

What Does Maintenance Factor Mean?The Maintenance Factor (MF) is a critical calculation for LED...

Lighting Terminology Glossary

Professional lighting terminology guide: This comprehensive glossary defines key lighting industry...

Understanding Pupil Lumens: Why LED Lights Appear Brighter Than Their Lumen Rating Suggests

Pupil Lumens is a concept that is not well-known outside of the lighting industry, but it is an...

Energy Efficient Lights for Warehouse Applications

Efficient warehousing is an integral component of modern supply chain strategy. As facilities...

How to Reduce Your Carbon Footprint

Carbon footprint measures the total greenhouse gas emissions generated by a facility's energy...