Metal Halide to LED Conversion Guide: Retrofit Kits vs Full Fixture Replacement

Upgrading metal halide (MH) lighting to LED is one of the fastest ways to reduce energy use, improve light quality, and cut maintenance in commercial and industrial spaces. In many facilities, the bigger problem isn’t just high wattage-it’s that metal halide systems lose light output over time, require frequent lamp/ballast service, and can’t use modern controls effectively.

This guide covers two upgrade paths:

- Complete fixture replacement (new LED fixtures)

- LED retrofit kits (convert the existing housing)

Metal Halide vs LED: Quick Comparison

| Category | Metal Halide (HID) | LED |

|---|---|---|

| Energy use | Higher wattage for similar maintained light levels | Typically 50-75% lower energy for comparable results (project-dependent) |

| Warm-up / restrike | Warm-up time and restrike delay after power interruption | Instant on and instant restart |

| Light depreciation | Significant lumen loss over life; color shift over time | Gradual depreciation; more stable color and output |

| Maintenance | Lamp + ballast service; lift rental and downtime add cost | Minimal scheduled maintenance; long service life |

| Controls | Poor fit for motion sensors due to warm-up/restrike | Excellent with photocells, motion sensors, and dimming |

| Environmental | Many HID lamps require special disposal | No mercury like HID/fluorescent; recycling options vary by product |

The Biggest Benefits LEDs Have Over Metal Halide Bulbs

1) Energy Savings

LEDs deliver more usable light per watt by combining efficient LED sources with optics that direct light where you need it. In many projects, switching from metal halide to LED reduces lighting energy consumption by 50-75%, depending on mounting height, layout, and target light levels.

2) Reduced Maintenance Costs

Metal halide systems require ongoing lamp and ballast maintenance-and those costs multiply when you factor in lifts, labor, downtime, and safety procedures. Quality LED systems are designed for long operating life (often 50,000+ hours), helping reduce service calls and relamping cycles.

Note: Metal halide also experiences substantial lumen depreciation over time-many systems deliver far less light at mid-life than they did when new.

3) Better Light Quality (CRI + Visibility)

CRI (Color Rendering Index) measures how accurately a light source reveals colors. Many metal halide systems start with fair-to-good CRI but can shift color as they age. LED options commonly include:

- Standard commercial LEDs: CRI 70-80 (common for basic industrial lighting)

- Premium LEDs: CRI 80-90+ (better color accuracy and visual comfort)

In task-oriented environments (like factories and maintenance bays), improved color rendering can support safety and accuracy.

4) Safety and Environmental Advantages

Many HID and fluorescent lamps contain materials that require special handling and disposal. LED systems contain no mercury, like many HID / fluorescent lamps, and are typically more impact-resistant than glass HID lamps, reducing breakage risk.

5) Instant On and Instant Restart

Metal halide systems require a warm-up period to reach full output and often have a restrike delay after a power interruption while the lamp cools and stabilizes. LEDs reach full brightness immediately and restart instantly-important for safety lighting and control strategies.

6) LEDs Work Well With Controls

LEDs pair well with photocells, motion sensors, timers, and dimming controls. Because LEDs switch instantly and can dim smoothly (when the driver supports it), controls can deliver additional savings beyond fixture efficiency alone.

Retrofit Kits vs Complete Fixture Replacement

There are two common ways to upgrade metal halide lighting:

Option A: Complete Fixture Replacement

Full replacement means removing the existing metal halide fixture (lamp, ballast, reflector, and housing) and installing a new LED fixture. This typically delivers the best performance, optics, sealing, and warranty coverage as a complete system.

Option B: LED Retrofit Kits (Convert the Existing Housing)

LED retrofit kits replace the internal light engine (and typically bypass/remove the ballast) while keeping the existing housing. Retrofit kits can be a good choice when the fixture body is in good condition, and you want to reduce material cost or simplify mechanical changes.

Should I Retrofit or Replace My Metal Halide Fixtures?

Both LED retrofit kits and full fixture replacements can be effective, but the right choice depends on the condition of your existing fixtures, performance requirements, and long-term goals. The table below outlines common decision factors we use when evaluating projects.

| Consideration | LED Retrofit Kit | Full LED Fixture Replacement |

|---|---|---|

| Existing housing condition | Good option if housing is structurally sound and weather-tight | Preferred if housings are corroded, cracked, or yellowed |

| Optical performance | Limited by original fixture geometry | Optimized optics designed specifically for LED |

| Upfront cost | Maybe as much as the new fixture costs | Similar upfront cost, often better long-term value |

| Installation scope | Internal rewiring and ballast bypass required | Remove and replace the entire fixture |

| Sealing & environmental rating | Depends on the existing housing condition | New IP/NEMA-rated enclosure |

| Warranty coverage | Applies to LED components only | Applies to the entire fixture as a system |

General guidance: Retrofit kits can work well when the existing fixture body is in good condition, and budget or access constraints favor reuse. Full replacement is often the better choice when you need improved optics, better environmental sealing, or a clean long-term solution.

Important Safety & Compliance Notice: Retrofit kits can require rewiring and ballast bypass. Final compatibility, wiring method, grounding, and code compliance must be verified by a licensed electrician and the authority having jurisdiction (AHJ). Always follow the retrofit kit’s installation instructions and safety labeling.

Which One Should You Choose?

- Choose retrofit kits when the housing is structurally sound, weather sealing is intact, and the fixture form factor still fits your needs.

- Choose full replacement when housings are corroded, lenses are yellowed/cracked, sealing is compromised, optics are poor, or you need better distribution/control options.

What Are Metal Halide Fixtures Used For?

Metal halide fixtures are common in commercial and industrial spaces. They can easily be upgraded and updated using:

- LED parking lot lights for area lighting

- LED flood lights for security lighting

- LED wall packs for exterior perimeter lighting

- High mast lighting for large area lighting

- Street and roadway lighting

Why Are Metal Halide Lights Sometimes Referred to as HID?

HID (High-Intensity Discharge) refers to a family of lamps that includes metal halide, high-pressure sodium, and mercury vapor. These systems typically use a lamp + ballast to operate. So while all metal halide lamps are HID, not all HID lamps are metal halide.

5 Practical Tips for Replacing Metal Halide With LED

1) 1-for-1 Replacement Is Often Possible (But Verify)

In many projects, a single LED fixture can replace a single metal halide fixture, sometimes with fewer fixtures overall, because LED optics deliver more controlled light distribution. However, the correct solution depends on mounting height, spacing, and target light levels. A photometric plan is the best way to verify results before purchasing.

2) Don’t Replace Watt-for-Watt

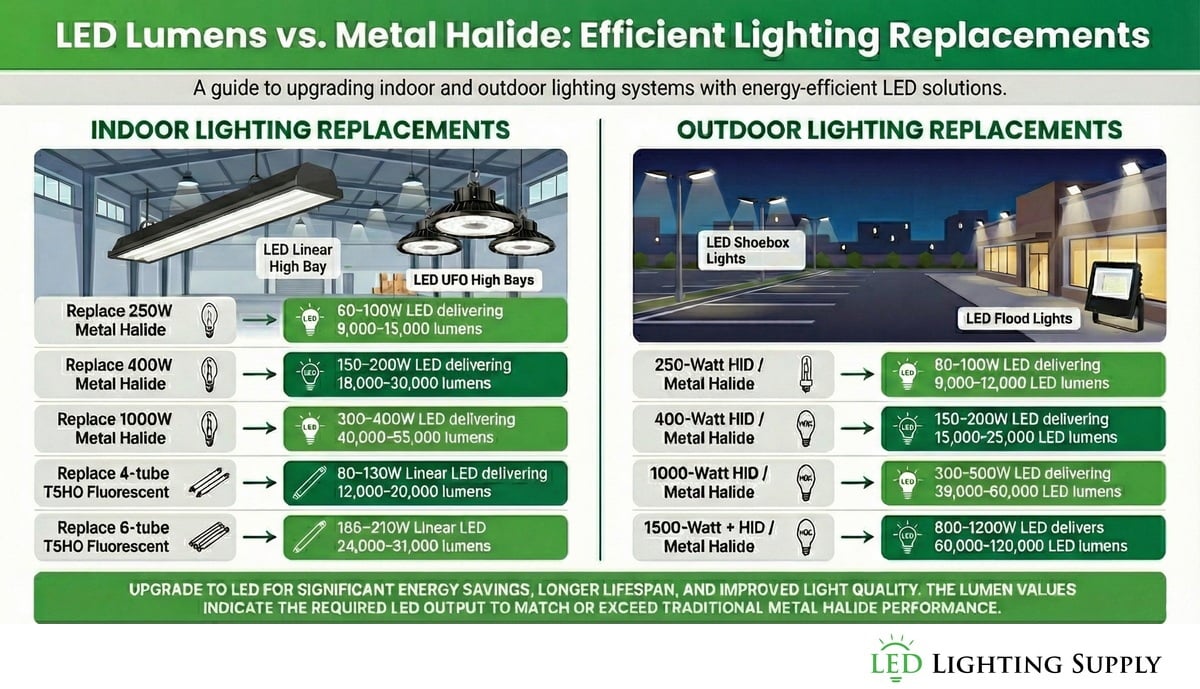

Never choose an LED by matching the old metal halide wattage. Select by lumens, optics, and required light levels. It’s common to replace:

- 400W metal halide with 100-200W LED (depending on fixture, layout, and goals)

- 1000W metal halide with 300-500W LED (application-dependent)

3) Confirm Voltage (and Driver Range)

Many LED fixtures support 120-277V input, with 277-480V options available on many commercial products. Confirm your site voltage before ordering, especially on commercial panels where 277V and 480V are common.

4) Controls and Dimming: Verify Driver Compatibility

Dimmers

- To dim, you typically need a 0-10V dimmable driver.

- Most 0-10V drivers use purple (+) and gray (-) control wires.

- Controls such as motion sensors can provide bi-level dimming or full shutoff strategies.

Motion Sensors & Photocells

- LEDs switch instantly and handle frequent on/off cycling well.

- That makes LED an excellent match for energy-saving controls in warehouses, yards, and exterior sites.

5) Understand LED Efficiency (Lumens per Watt)

Lumens per watt (lm/W) helps you compare efficiency. If two fixtures output the same lumens, the one using fewer watts costs less to operate.

Example: A 15,000-lumen fixture at 150W delivers 100 lm/W. A 15,000-lumen fixture at 100W delivers 150 lm/W. Both provide the same output, but the more efficient option reduces operating costs long-term.

Want Help Selecting the Right LED Replacement?

If you want to eliminate guesswork, we can recommend the right LED fixture or retrofit kit based on:

- Mounting height and fixture spacing

- Target light levels (foot-candles/lux) and uniformity goals

- Optic/distribution needs (narrow, wide, Type patterns)

- Voltage, controls, and environmental conditions

Tip: If this is a larger space or outdoor site, request a photometric plan to verify coverage and avoid costly rework.

What We Need to Recommend the Right LED Replacement

To accurately recommend an LED fixture or retrofit kit that meets your performance, safety, and efficiency goals, we typically review the following information. Providing these details helps avoid under-lighting, over-lighting, and unnecessary fixture count.

- Mounting height and spacing of existing fixtures

- Application type (warehouse, parking lot, yard, sports, roadway, etc.)

- Target light levels (foot-candles or lux, if known)

- Existing fixture details (metal halide wattage, quantity, housing type)

- Voltage (120V, 277V, 480V, or mixed)

- Environmental exposure (outdoor, wet location, corrosion risk)

- Control requirements (photocells, motion sensors, dimming)

For larger or outdoor projects: We strongly recommend a photometric lighting plan to confirm coverage, uniformity, and fixture quantity before ordering. This helps eliminate guesswork and reduces the risk of costly changes after installation.