Replacing a 400 Watt Metal Halide with LED: Wattage, Lumens, and Real-World Savings

What Does it Take to Replace 400 Watts Metal Halide Bulb with LED?

Converting from 400-watt metal halide to LED involves more than simply matching wattage numbers. After 15+ years in commercial lighting, we have seen countless customers make costly mistakes by focusing on watts instead of actual light output. The reality is that a properly selected 150 watt LED can easily replace your 400-watt metal halide while delivering superior light quality and 67% energy savings.

Metal halide replacement requires understanding lumens, not watts. Your existing 400-watt metal halide consumes approximately 460 total watts (including ballast overhead) while producing around 30,000 initial lumens. However, that output degrades rapidly, losing nearly half its brightness by mid-life. Most customers are surprised to learn that our LED replacements maintain consistent output for 100,000+ hours (L70, model-dependent) while using significantly less energy.

Whether you’re upgrading lighting in a warehouse, parking lot, gym, manufacturing facility, workshop, or tennis court, the conversion process follows the same principles. Smart facility managers rely on professional lighting plans rather than guesswork. We’ve guided thousands of successful conversions across indoor and outdoor applications.

Important: Final fixture selection, wiring method, voltage compatibility, and code compliance must be verified by a licensed electrician and your local authority.

Replacing 400W Metal Halide with LED

- High Bay Lighting: High Bay LED Light Replacement

- NSF Food Processing: 400 Watt Equivalent LED NSF Fixtures

- Shop Lighting: 400 Watt Equivalent LED Shop Lights

- Flood Lighting: 400 Watt Equivalent LED Flood Lights

- Shoebox Parking: 400 Watt Equivalent LED Parking Lot Lights

- Wall Pack Lighting: 400 Watt Equivalent LED Wall Packs

- Sports Lighting: 400 Watt Equivalent LED Sport Lights

How Many LED Watts Replace a 400 Watt Metal Halide?

Purchasing LED fixtures based on wattage alone leads to oversized, inefficient installations. A 400-watt LED would produce excessive light output, roughly 60,000+ lumens, creating uncomfortable glare while wasting energy. Even comparing LED watts to other LED watts proves unreliable since efficacy varies dramatically between manufacturers and models.

Modern LED technology achieves 130 to 160 lumens per watt, compared to metal halide’s 65-75 lumens per watt when accounting for ballast losses and lumen depreciation. This efficiency gap explains why significantly lower LED wattage delivers equivalent or superior illumination.

Focus on lumens-the actual light output your space requires. We typically recommend analyzing your current foot-candle levels and designing around those measurements rather than arbitrary wattage matching.

We helped this customer light up his sport court with LED pickleball court lights

Understanding Lumens vs Traditional Wattage Measurements

Traditional lighting systems like metal halide and HPS were sized purely by wattage consumption because their efficacy remained relatively constant across manufacturers. LEDs changed everything by dramatically improving the light-per-watt ratio while introducing significant variation between products.

Defining Lumens for LED Selection

Lumens measure total visible light output from any source. When electricity converts to light within an LED fixture, the resulting lumens represent useful illumination reaching your workspace. Unlike wattage, which only indicates energy consumption, lumen output directly correlates with perceived brightness and task visibility.

LED fixtures excel at converting electrical input into visible light with minimal heat waste. Where your 400-watt metal halide generates substantial infrared radiation and heat, LED fixtures channel 85-90% of input energy directly into usable lumens.

Foot Candles: Measuring Light Distribution

One foot candle equals one lumen distributed over one square foot of surface area. This measurement determines whether your lighting meets industry standards for specific applications. Office spaces typically require 30-50 foot candles, while manufacturing areas need 50-100 foot candles for detailed work.

Professional lighting software calculates foot candle distribution by analyzing fixture placement, mounting height, beam angles, and lumen output. The software accounts for how multiple fixtures interact to create uniform illumination patterns.

Professional Lighting Plans Eliminate Guesswork

A comprehensive lighting plan transforms your conversion from estimation to precise engineering. Our photometric analysis determines exact fixture requirements based on your space dimensions, ceiling height, task requirements, and existing mounting locations.

The plan reveals hot spots, dark areas, and optimal fixture spacing before installation begins. Most customers discover they need fewer fixtures than anticipated, often reducing project costs by 20-30% compared to one-for-one replacement approaches.

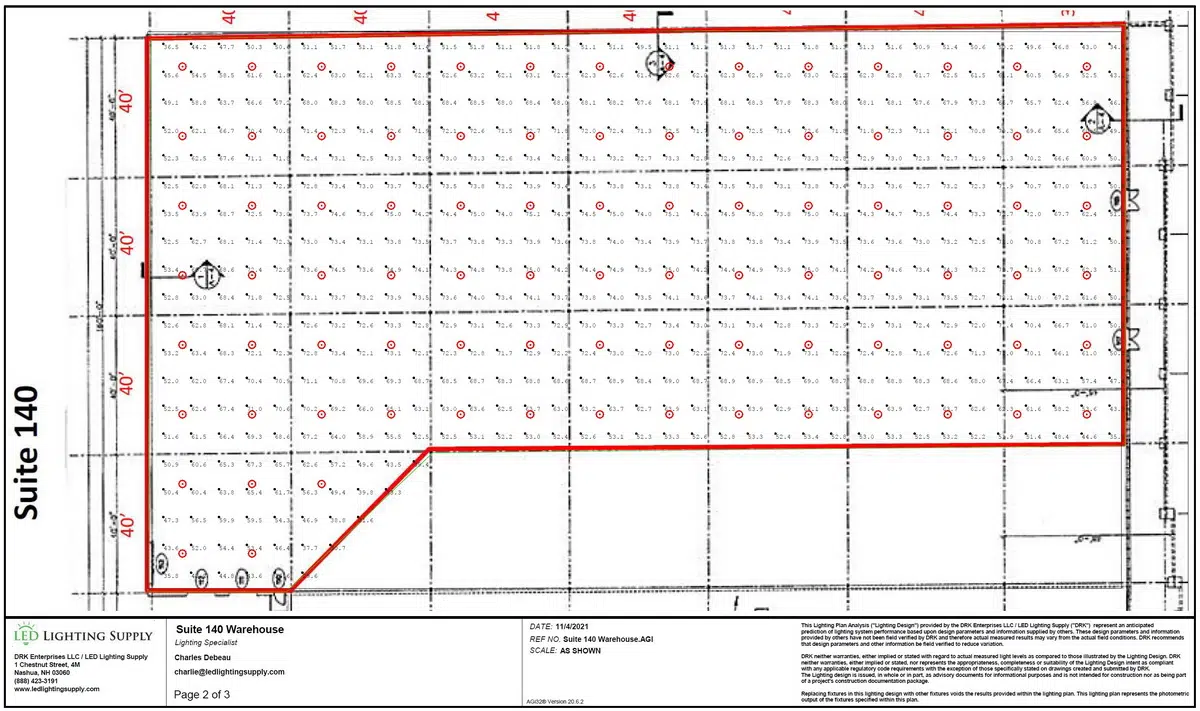

Case Study: Installation of new LED Lighting for Stone Basyx in Charlotte, NC

|

After: 150 Watt High Output UFO High Bay | 24000 Lumens |

|

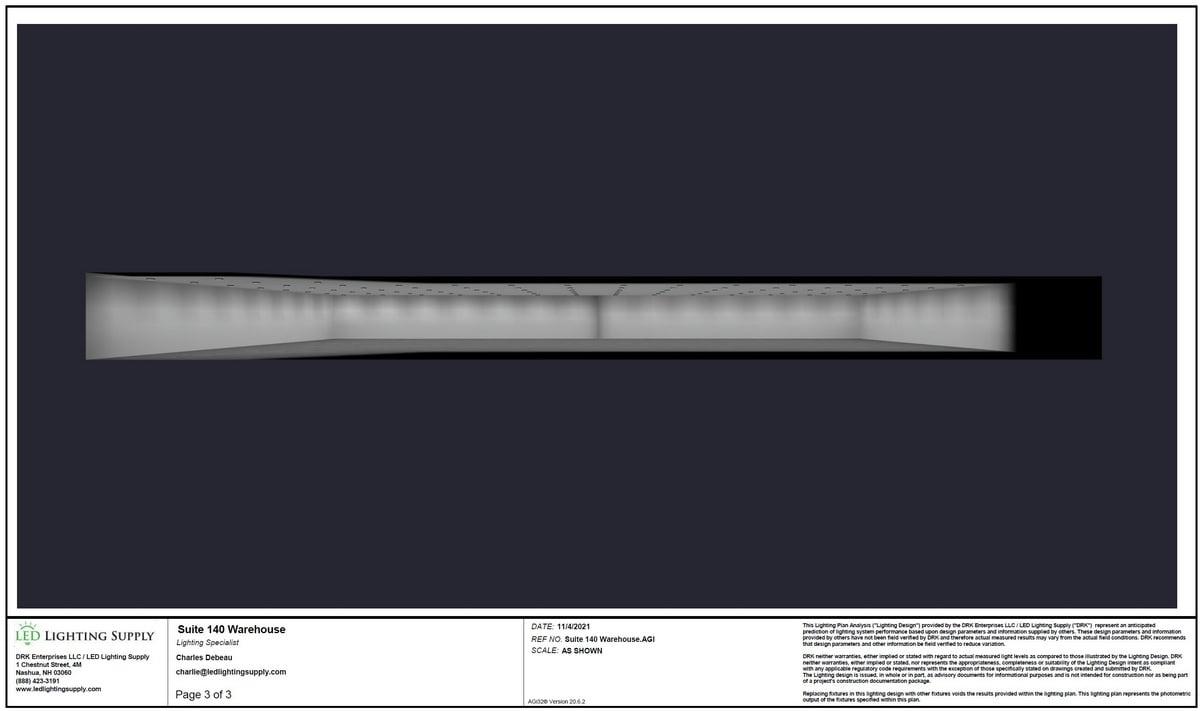

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

Warehouse / Retail Lighting Installation Plan Metrics

- Mounting height: 23 ft

- Fixture Used: MLLG-LED-HBHO-150-5-120: 80 / 100 / 120 / 150 Watt Adjustable UFO High Bay | 16000 to 30000 Lumens | 5000K | 100-277V | High Performance

- FC achieved: 65.36 FC average

- Uniformity (Avg/Min): 2.21

What are the Cost Savings and ROI When You Convert from Metal Halide to LED?

150W LED UFO High Bay vs 400W Metal Halide Replacement (with ballast)

Assumptions: Based on 16 hours/day, 220 days/year at $0.20/kWh,

50 fixture(s), and a 15% ballast factor applied to the metal halide wattage

(400W lamp + 15% ballast = ~ 460W input).

•

Energy cost and ROI calculations are based on energy savings only and assume an LED fixture cost of

$100.00 per fixture.

• Maintenance savings from reduced bulb and ballast replacements are not included

in these calculations.

| Metal Halide (460W per fixture) |

Annual Energy Cost (per fixture): $323.84 Annual Energy Cost (all 50 fixtures): $16,192.00 5 Year Energy Cost (all fixtures): $80,960.00 5 Year Savings (all fixtures): $0.00 |

| LED UFO High Bay (150W per fixture) |

Annual Energy Cost (per fixture): $105.60 Annual Energy Cost (all 50 fixtures): $5,280.00 5 Year Energy Cost (all fixtures): $26,400.00 5 Year Savings (all fixtures): $54,560.00 |

| Savings & Payback |

Single Fixture Annual Savings (energy only): $218.24 50 Fixture Annual Savings (energy only): $10,912.00 LED Fixture Project Cost (50 fixtures): $5,000.00 Simple Payback from Energy Savings Only: under 6 months |

| Performance Summary |

Energy Reduction: 67% 5-Year ROI (All Fixtures, Energy Only): 991% Lamp Life: 50,000+ (LED) vs 15,000 (MH) |

In this example with 50 fixture(s), total LED fixture investment is approximately $5,000.00, and estimated annual energy-only savings are $10,912.00. Simple payback based on energy savings alone is under 6 months. Maintenance savings from eliminating metal halide bulb and ballast replacements provide additional value throughout the fixture's 50,000-hour lifespan, but are not included in this ROI calculation.

Maintenance Cost Elimination

LED conversion eliminates the ongoing expense cycle inherent with metal halide systems. Traditional fixtures require ballast replacement every 3-5 years at $80 to 120 per unit, plus bulb changes every 12-18 months at $40-60 each.

Our LED fixtures operate maintenance-free for 10-15 years under typical usage. No ballasts to fail, no bulbs to replace, no lift rentals for high-bay maintenance. Facilities with 100+ fixtures often save $5,000 to 8,000 annually in maintenance labor and materials alone.

Light Quality: Why CRI Matters for LED Selection

Superior light quality allows LED fixtures to provide better visibility with fewer lumens than metal halide equivalents. The Color Rendering Index (CRI) measures how accurately colors appear under artificial light compared to natural sunlight.

Standard metal halides produce CRI 65-75, while quality LED fixtures achieve CRI 80-90+. This improvement means tasks requiring color differentiation-reading labels, identifying wire colors, and quality inspection-become noticeably easier under LED illumination.

We regularly specify LED fixtures with 20% fewer lumens than the metal halides they replace, yet customers report dramatically improved visibility. Higher CRI reduces eye strain and increases productivity, particularly in detailed work environments.

Metal Halide Lumen Depreciation vs LED L70 Performance

New 400-watt metal halide lamps generate approximately 30,000 initial lumens. However, rapid depreciation begins immediately, losing 20% output within 6 months and 50% by mid-life at 7,500 hours. By replacement time, most metal halides deliver only 15,000-18,000 usable lumens.

The L70 rating indicates when fixtures drop to 70% of their initial output. Metal halide L70 occurs around 5,000 hours, while our LED fixtures maintain L70 performance for 100,000+ hours. This consistency means LED installations actually become relatively brighter over time as they maintain steady output.

Facilities often discover their existing lighting feels inadequate, not due to insufficient initial design, but because aging metal halides have lost substantial output. Fresh LED installations frequently appear dramatically brighter simply by restoring intended illumination levels.

Directional LED Light vs Omnidirectional Losses

LED fixtures emit directional light that efficiently targets work surfaces without requiring reflectors. Metal halide lamps produce omnidirectional light-radiating in all directions, necessitating reflectors to redirect useful illumination downward.

Each reflection within traditional fixtures causes 5-8% lumen loss. Multiple bounces compound these losses, resulting in 25 to 35% total reduction from lamp rating to actual delivered light. A 30,000-lumen metal halide typically delivers only 21,000 effective lumens to the workspace.

LED fixtures eliminate reflection losses. Their directional output, combined with precisely engineered optics, delivers 90 to 95% of rated lumens directly to intended surfaces. This efficiency advantage further reduces the LED wattage required for equivalent illumination.

Photopic vs Scotopic Vision: How Eyes Perceive LED Light

Human vision responds differently to various light spectrums, affecting how bright fixtures appear, regardless of measured lumen output. Understanding photopic and scotopic vision explains why LED fixtures often seem brighter than their lumen ratings suggest.

Cone Cells and Photopic Response

Cone cells concentrated in the eye’s central fovea region handle color vision and bright light conditions. These cells respond optimally to the 4000K to 5000K color temperature range common in quality LED fixtures. Standard light meters calibrate to cone cell response, measuring photopic lumens.

Rod Cells and Low-Light Sensitivity

Rod cells distributed throughout the retina manage peripheral and low-light vision. Rods cannot distinguish colors but show enhanced sensitivity to the blue-rich spectrum produced by LED fixtures. This creates the scotopic advantage-LEDs appear brighter to peripheral vision than light meters indicate.

Spectral Distribution Advantages

Metal halide lamps produce significant infrared and ultraviolet radiation invisible to human vision but registered by light meters as lumens. LED fixtures concentrate output in the 400-700 nanometer visible spectrum, maximizing useful illumination per measured lumen.

Professional LED Conversion Planning Process

LED Lighting Supply has completed thousands of successful metal halide conversions across warehouse, manufacturing, retail, and outdoor applications. Our proven methodology eliminates guesswork while ensuring optimal performance and maximum energy savings.

Every project begins with a detailed facility assessment, including current fixture inventory, mounting heights, electrical infrastructure, and usage patterns. We then create customized photometric plans showing foot candle distribution, uniformity ratios, and fixture specifications tailored to your operational requirements.

Whether you’re upgrading a small shop or a million-square-foot distribution center, our lighting specialists provide the technical expertise needed for successful LED conversion. We handle everything from initial consultation through product specification and installation support.

Contact us for your complimentary lighting plan and discover how much you can save with professional LED conversion.

Why Choose LED Lighting Supply for Your Metal Halide Conversion

Our experienced product specialists have guided thousands of successful conversions with detailed energy savings calculations customized to your exact electrical rates and usage patterns. We track actual customer results showing average savings of $275-425 annually per fixture based on real-world data from completed projects. Our complimentary custom lighting plans use professional-grade photometric software to determine precise fixture requirements, often reducing initial project costs by 20-30% compared to generic one-for-one replacements. Unlike general electrical distributors, our team focuses exclusively on commercial LED conversions and understands the technical nuances that separate successful installations from costly mistakes.