LED Replacement for 1000W Metal Halide: Power Requirements and Specifications

A 1000-watt metal halide fixture typically requires a 300 to 400 watt LED replacement producing approximately 45,000-65,000 lumens. This can deliver up to 70% energy savings while improving light quality and reducing maintenance requirements.

Metal halide fixtures have been widely used in commercial and industrial applications due to their high light output. However, these systems consume significant energy and require regular maintenance for bulb and ballast replacements.

LED conversions can benefit facilities, including using these light types:

- LED warehouse lights,

- LED factory lights

- LED stadium lights

- LED sports field lights

- LED parking lot lights

The conversion eliminates frequent bulb replacements and ballast maintenance while providing consistent light output over time.

Important Safety Notice: All fixture replacements must be performed by a licensed electrician and comply with local electrical codes. Voltage compatibility, mounting requirements, and proper installation methods must be verified before proceeding.

Power Consumption Comparison: Metal Halide vs LED

Understanding the total system power draw helps calculate potential energy savings:

Metal Halide System Total Consumption

- Lamp Power: 1000W

- Ballast Power: 100-150W additional

- Total System Draw: 1100-1150W

LED System Consumption

- Total Power Draw: 300-400W

- Net Energy Reduction: 700-850 watts per fixture

To calculate potential savings, multiply the per-fixture reduction by your total fixture count and operating hours. Actual savings depend on local energy rates and usage patterns.

Key Factors for LED Replacement Selection

Lumen Output vs Power Consumption

Focus on delivered lumens rather than matching wattage numbers. Modern LED fixtures typically produce 120-160 lumens per watt, significantly higher than metal halide systems at 70-90 lumens per watt.

A 300-watt LED fixture producing 45,000 lumens often provides equivalent or superior illumination compared to a 1000W metal halide system, depending on application requirements.

Light Quality Considerations

LED technology offers superior color rendering compared to many traditional sources:

- LED CRI: Typically 70-90+ (higher values available)

- Metal Halide CRI: Usually 65-90

- High Pressure Sodium CRI: Approximately 22

Higher CRI values improve visual clarity and can reduce the total lumens needed for effective illumination.

Technical Considerations for Metal Halide to LED Conversion

Optical Efficiency Differences

Metal halide lamps emit light in all directions, requiring reflectors to redirect illumination. This process can reduce effective light output by 20-40%, depending on reflector design and condition.

LED fixtures produce directional light, eliminating many reflector losses. When secondary optics are used for specific beam patterns, efficiency losses are typically much lower thanthose of traditional reflector systems.

Lumen Maintenance Over Time

Metal halide lamps experience significant lumen depreciation:

- Initial output: 70,000-110,000 lumens for 1000W systems

- Output after 40% of rated life: Often 70-80% of initial lumens

- Typical lamp life: 15,000-20,000 hours

Quality LED fixtures maintain 90% or more of their initial output at 50,000+ hours of operation.

Case Study: Conversion of existing lighting in Baseball / Softball Field to LED Lighting Supply 600 Watt LED Sports Lights at Gainesville High school in Gainseville, MO

|

After: 600 Watt LED Area Sports Flood Light | 84000 Lumens |

After: 600 Watt LED Area Sports Flood Light | 84000 Lumens |

|

|

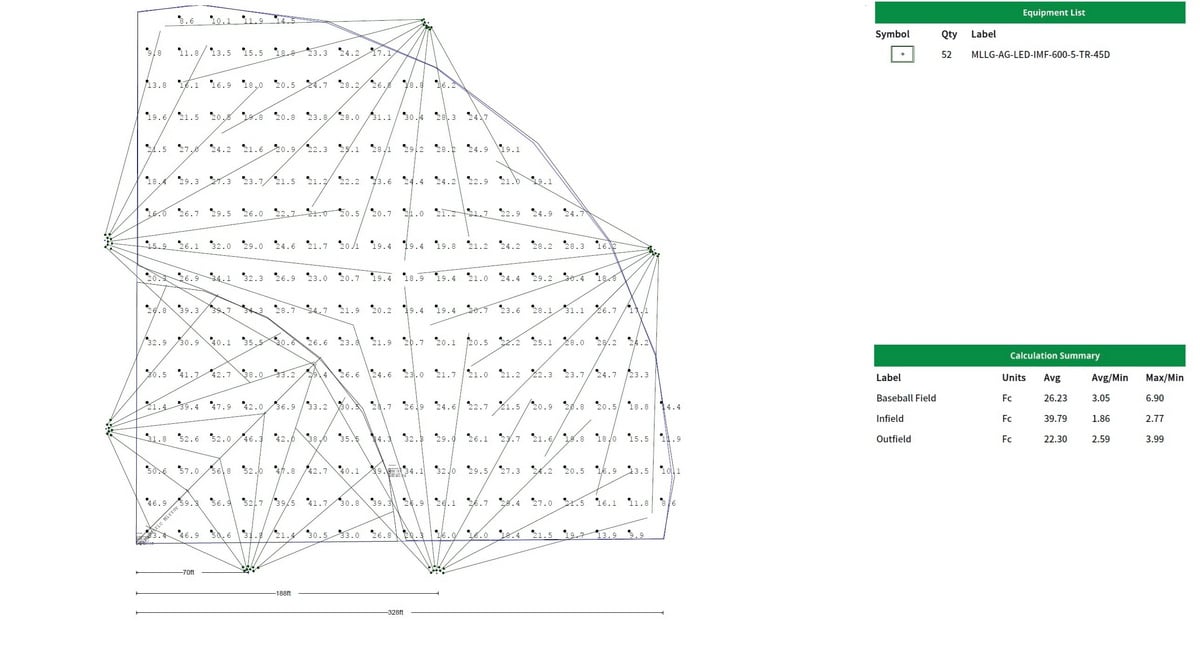

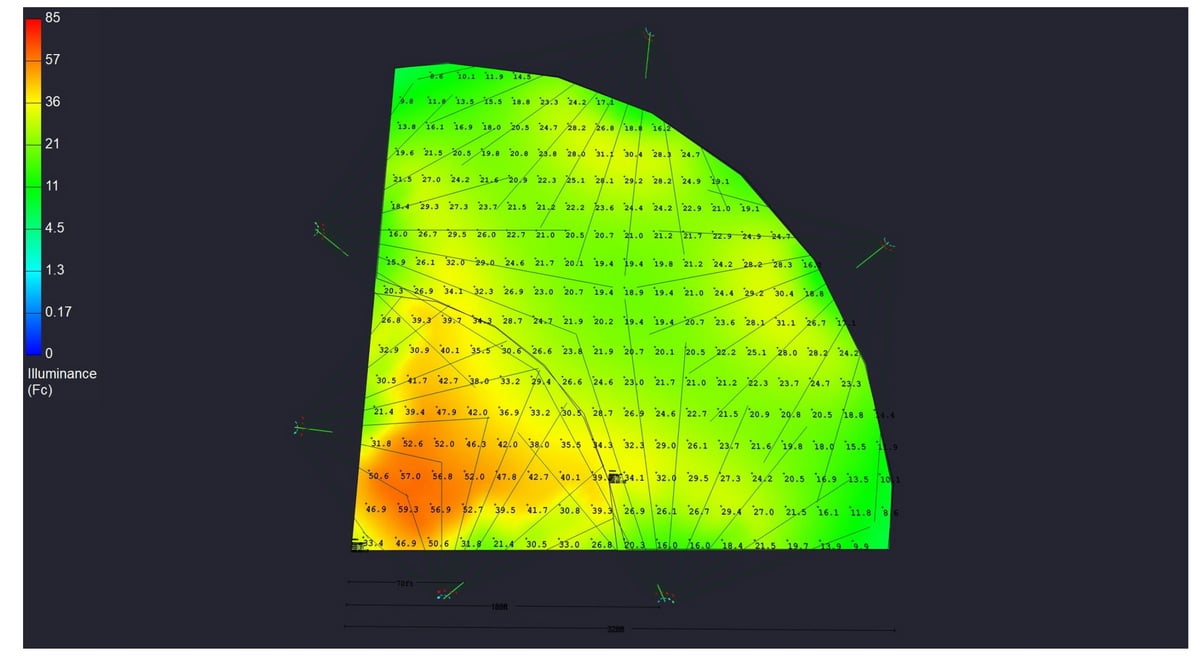

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

Baseball / Softball Field Lighting Installation Plan Metrics

- Mounting height: 47 and 50 ft

- Fixture Used: MLLG-AG-LED-IMF-600-5-[Optic]-TR-[V]: 600 Watt LED Flood Light | 84000 Lumens | 5000K | 100V-277V or 277V-480V

- FC achieved: 39.79 FC (infield), 22.30 FC (outfield) average

- Uniformity (Avg/Min): 2.35

Information Needed for Proper LED Replacement Selection

The correct LED replacement depends on specific application requirements. Key factors include:

- Application type: High bay, sports lighting, parking lot, flood lighting

- Mounting height: Critical for optics and beam angle selection

- Fixture spacing: Existing layout and coverage area

- Voltage requirements: 120V, 277V, 480V compatibility

- Target light levels: Required foot-candles or lux

- Light distribution needs: Beam angles, cutoff requirements

- Control compatibility: Sensors, dimming, or photocells

Common LED Replacement Categories

- High Bays: 1000W High Bay LED Replacements

- Sports Lighting: 1000W Sports Light LED Replacements

- High Mast: 1000W Equivalent LED High Mast Lights

- Flood Lights: 1000W Equivalent LED Flood Lights

- Parking Lots: 1000W Equivalent LED Parking Lot Lights

Professional Recommendation: For critical applications requiring specific uniformity or light levels, photometric analysis should be performed to verify fixture count and placement before installation.

Frequently Asked Questions

How Many Lumens Does a 1000W Metal Halide Produce?

New 1000W metal halide lamps typically produce 70,000 to 110,000 initial lumens, depending on lamp type and manufacturer. However, this output degrades over time, with most lamps losing 20-30% of their initial output by mid-life.

For replacement calculations, focus on the lumens required for your specific application rather than trying to match initial lamp ratings.

What LED Wattage Replaces 1000W Metal Halide?

Most applications use 300 to 400 watt LED fixtures to replace 1000W metal halide systems. The exact wattage depends on:

- Required light levels

- Mounting height

- Beam angle requirements

- Application type

Quality LED fixtures operating at 120-160 lumens per watt provide the efficiency needed for significant energy savings.

What LED Replaces 1000W High Pressure Sodium?

A 300 to 400 watt LED system typically provides equivalent or superior illumination compared to 1000W HPS fixtures. The LED system offers much better color rendering (CRI 70+ vs 22 for HPS) and more even light distribution.

How Long Do 1000W Metal Halide Lamps Last?

Metal halide lamps are typically rated for 15,000-20,000 hours of operation. However, light output degrades continuously during this period, with a significant reduction noticeable by mid-life.

LED fixtures often maintain 90%+ of initial output at 50,000+ hours, providing both longer life and more consistent performance.

Professional LED Conversion Services

LED Lighting Supply provides photometric lighting plans designed for specific facility requirements. Our lighting specialists use professional software to calculate fixture placement and verify performance before installation.

These custom plans include energy savings calculations and ensure optimal coverage while avoiding over-lighting. Contact our technical team to discuss your specific metal halide conversion project.

Next Steps: For professional guidance on your 1000W metal halide conversion, contact our lighting specialists for a consultation and custom photometric analysis.