LED Lumens Explained: Understanding Brightness, Efficiency, and Light Quality

LED Lumens – There is No Comparison

LED lighting has become the dominant technology across residential, commercial, and industrial applications due to measurable improvements in efficiency, controllability, and light quality. Compared to legacy lighting technologies, LEDs typically deliver higher usable light output with lower energy consumption, longer service life, and greater compatibility with controls.

They also provide significant energy-efficient benefits that save large amounts of money on energy costs. And their better quality light improves work morale and efficiency, making them perfect for LED industrial lighting and LED commercial lighting applications.

Whether you’re illuminating a large warehouse with a complex LED system or shopping for a ceiling light to install in your office, it all comes down to lumens. Business owners and other professionals upgrading their lighting to LED fixtures frequently ask us about lumens. There isn’t really a straightforward answer. Why? Read on, because we’re about to go over every aspect of lumens and how to use them to ensure that your LED conversion results in a prime product.

Important note: Lighting performance, energy savings, and lumen equivalency vary based on fixture design, optics, mounting height, spacing, operating hours, and application. The examples in this guide are provided for general education and comparison purposes only.

What are Watts?

Before diving into lumens, we need to quickly cover watts. It’s actually quite simple. A watt measures energy consumption, specifically the rate of power used when one amp flows through an electrical resistance of one volt. Watts remain the most common lighting measurement, and most people are generally familiar with what they represent in traditional lighting terms.

What are Lumens?

Now that we’ve covered watts, we can explore the ins and outs of lumens and LED lighting. But what are lumens, exactly?

The technical definition of a lumen is: “a unit of luminous flux in the International System of Units. It is equal to the amount of light detected through a solid angle by a source of one-candela intensity.” Simply put, lumens measure the amount of visible light that a bulb produces. Many people mistakenly believe that “watts” is the term to use here.

This confusion stems from decades of shopping for bulbs based on wattage for home lighting. Higher watts on traditional lightbulbs meant brighter light. Remember our definition of watts earlier-they measure energy consumption. While higher energy consumption once equaled brighter light, that’s certainly not the case today.

Old habits die hard. Even though an LED light can produce noticeably more powerful illumination than a traditional bulb while using less energy, the average person still relies on watts. Because LEDs are so much more energy-efficient than other types of lighting, we specifically use lumens to designate their light output.

More Light, Less Energy ( Watts ) with LED

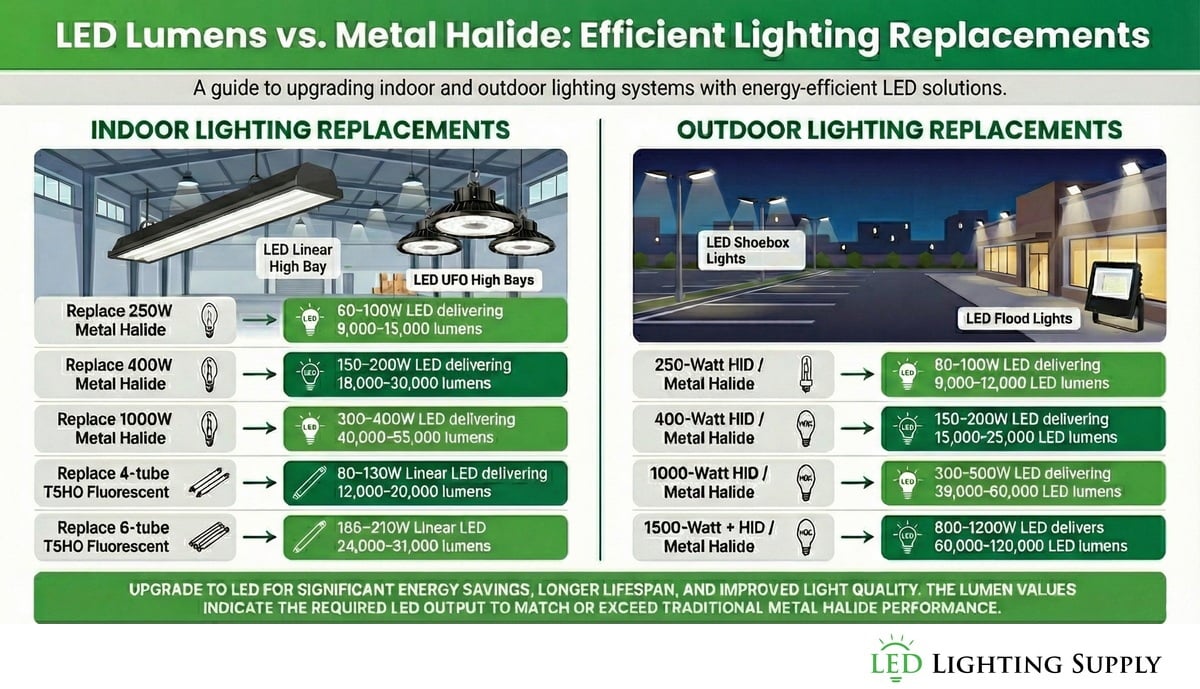

With low-energy LED lamps, more light output can be achieved with much less power consumption. In many commercial applications, a properly designed 150W LED fixture can deliver comparable usable illumination to a 400W metal halide system when optics, mounting height, and distribution are matched appropriately. Actual equivalency depends on fixture design and application conditions. That is 66% less energy (including the metal halide ballast draw) for the same light output.

LED lights produce very little heat when they convert electricity to light. This minimizes waste and gives us the efficient shine that we love LEDs for. As technology improves, this efficiency margin will become even larger. More and more lumens will be produced using fewer and fewer watts. While watts remain important for understanding energy consumption, lumens and efficacy have become the primary metrics for evaluating lighting performance in modern LED systems.

Lumens and Useful Lumens

With any type of bulb, some of the light emitted will be lost through reflections or diffusions. LED bulbs significantly limit the amount of light lost because they’re manufactured to be directional, but some loss is unavoidable. Because of this, the EU has recently introduced something called a “useful lumens” rating. This new measurement accounts for the useful light emitted by a bulb. The “useful lumen” rating is typically lower than the total lumen output but offers a slightly more accurate prediction of how bright the light will actually be in real-world applications.

Lumens & Directional Light Sources

With a directional light source, you need fewer lumens. LED light is an intrinsically directional light source. While there are LED bulbs that provide multi-directional lighting, they are specifically engineered to do so and account for any lost light. In other words, lighting engineers design fixtures or bulbs with LED chips in different positions to provide non-directional lighting and prevent excess loss of light. LED chips themselves provide one-directional lighting.

Conventional light sources, such as metal halide, high-pressure sodium, fluorescent bulbs, and incandescent bulbs, are all omnidirectional light sources. They produce light in every direction. So, as a general light source for home use, they work well.

However, specialized commercial and industrial environments like warehouses, factories, and other commercial facilities need reflectors to gather and ‘collect’ the light to focus it and direct it to where it’s usable. The problem with reflected light sources is that a large margin of the light produced becomes unusable, otherwise known as lost lumens. Any internal reflection that is over one bounce effectively loses the light of one lumen.

Consider metal halide bulbs as an example. Like LEDs, they’re popular for commercial lighting and industrial lighting applications. Unlike LEDs, they are not directional. Light particles produced by a metal halide bulb rarely reach the floor without being reflected by at least one surface. When a light particle is produced, it likely hits the fixture’s reflector, which then tries to direct it toward the floor. If unsuccessful, it sends the particle to another section of the fixture’s reflector to repeat the process.

In reflector-based omnidirectional systems, a meaningful portion of generated light may be lost through multiple internal reflections. Depending on fixture design and reflector efficiency, these losses can be significant compared to directional LED systems that deliver light directly toward the target area.

Lumens Quality over Quantity

You need fewer lumens when you have better lumens. The quality of light that any light source emits is measured by the Color Rendering Index or CRI. CRI is a scale measuring the accuracy of colors produced under a specific light source. The gold standard is, of course, the sun, which is given a score of 100.

Everything else is rated on a scale between 1 and 100. The best explanation of the quality of light is by performing a simple test. Compare an LED light to a High-Pressure Sodium (HPS) light. In our experience, it is not uncommon to have people tell you that 20,000 lumens of LED appear to be much brighter than 60,000 lumens of HPS.

LED CRI ratings are at least 70. For HPS, it’s 22. HPS lights are notoriously known for coloring anything that appears below them with a yellow and brown tinge. You can easily anticipate this if you look at the CRI value of light before you buy it. With a better quality of light, you need less of it. The higher a light’s CRI ratings, the fewer lumens it needs to create the ideal illumination. When shopping for LEDs, comparing lumens alone, apples to apples, is not valid unless you take the bulb’s CRI into account.

Photopic and Scotopic Lumens

Two ways to perceive lumens.

What are Photopic Lumens?

Humans have both cones and rods in their eyes, allowing them to perceive different levels of light and color. Photopic lumens can only be detected by light meters and the cones within an eye. This type of light is measured by standard lumens and foot-candles meters.

What are Scotopic Lumens?

Scotopic lumens represent the amount of light detected by both the rods and cones of the human eye. This light directly controls pupil size, which affects visual acuity when doing tasks. LED lights produce lumens that fall within the range of the spectrum visible to the human eye, meaning the light created by LEDs is usable. LED light does not produce infrared or UV spectrums unless specifically included in the LED package of the fixture.

These wavelengths are invisible to people, so they have no value from a vision perspective. Scotopic lumens use a factor to adjust the photopic value of light. In lighting terminology, these are called S/P Ratios (Scotopic/Photopic Ratios). S/P ratios give us a truer representation of how useful the lumens a light produces are.

This factor, developed by scientists, attempts to level the playing field. The factor adjusts the effective value of the lumen, which may move the photopic lumen up or down. HPS lights have a factor that reduces the effective scotopic lumen amount. LED has a factor greater than 1.7, which means the lumens it produces are far more effective for us. Fewer photopic LED lumens are needed to provide adequate lighting, whereas HPS fixtures require more lumens to effectively light up an area. To learn more about what S/P Ratios are for different light sources, click here.

Lumen Degradation of Metal Halide Versus LED

HID bulbs, like Metal Halides, commonly lose up to 50% of their initial lumens after only 5,000 hours of life. What’s even more concerning is that these bulbs are rated for 15,000 to 20,000 hours. The bulb has been performing poorly for almost 15,000 hours of its life. In addition to the degradation of lumens, the quality of the light (CRI) in HID fixtures also experiences significant losses.

Many sports organizations, which often use HID fixtures for stadium / sports field and gymnasium lighting, recommend replacing Metal Halide bulbs after only 3,000 hours of use. For a bulb rated for 15,000 hours of active life, the bulbs are only 20% used before they need replacing. This measurement gives you a good idea of just how quickly these bulbs degrade. LED light sources commonly have 50,000 to 100,000 hours of life, where they still maintain 70% of their initial lumens.

LED lumens degrade very slowly. The feedback we get often indicates that the lights appear much brighter than the ones they’re replacing, while saving money on energy costs. When you consider the quality of lumens from LEDs, their naturally higher CRI rating, and their longer usable lifespan, this is a natural conclusion.

Important: LED lumen maintenance is commonly referenced using industry standards such as L70, which indicates the point at which a light source maintains 70% of its initial output. Many commercial LED fixtures are designed for 50,000 hours or more to L70 under rated operating conditions.

LED Lumens – Seeing Things in a New Light

When we first entered the commercial and industrial lighting scene in 2008, there were many questions about LEDs, lumens, and fixtures in general. The most common question by far was “Why should I upgrade to LEDs?“

Today, LEDs are extremely common, and most people understand the many benefits that LED lighting offers. These questions get asked less and less. Instead, what we see most often now is business owners and facility managers reaching out to learn more about the process of converting their industrial and commercial lights to LED fixtures.

They know that LEDs are more energy-efficient and last much longer than other bulbs. LED lights are now the standard. They’re recognized all over the globe as money-saving, maintenance-free fixtures that can adapt to virtually any application, including underwater and in extreme temperatures.

People know that LEDs are better, but they want to know why. This can all be boiled down to LEDs and the lumens that they emit. They produce better, higher-quality lumens using less energy. This helps customers with electrical costs and increases employee productivity and satisfaction. LEDs, on average, maintain their initial lumen output for 50,000 hours.

This cuts down on maintenance costs because you rarely have to replace them. The lumens LEDs emit have a higher CRI rating, which creates a better atmosphere in your facilities. You could say that LED lumens are the reason for LED’s success.

How Many Lumens Do I Need?

- Step 1: Measure the square footage of the room you’ll be lighting. To do this, just multiply the length of the room by the width of the room.

- Step 2: Decide what foot candles are appropriate for your space. Lighting requirements vary greatly based on the room’s purpose. Office spaces require more foot candles than warehouses, for example.

- Step 3: Calculate how many lumens you need. As long as you’ve followed the first two steps, there’s a straightforward equation. To determine the number of lumens your space needs, multiply the square footage by the foot-candle requirements.

Design reminder: Target foot-candle levels should be based on recognized recommendations, such as IES guidelines, and verified through photometric analysis rather than estimated solely from square footage.

Professional Lighting Analysis and Custom Solutions

At LED Lighting Supply, our experienced lighting specialists provide complimentary custom lighting plans tailored specifically to your facility’s requirements. We analyze your current lighting setup and create detailed energy savings calculations that show your exact dollar savings and payback period. Our team has over 15 years of experience designing LED solutions for complex industrial and commercial applications.

We provide photometric analysis that ensures proper light distribution and foot-candle levels for your specific space. This professional analysis eliminates guesswork and guarantees you’ll achieve optimal lighting performance while maximizing your energy cost reductions.

Our recommendations are based on over 15 years of commercial and industrial LED lighting experience, supported by photometric modeling and real-world installation feedback across warehouses, factories, sports facilities, and outdoor environments.