Showing all 9 results

- SKU:MLLG-WG-POLE-CP-15-4SQ-DB | Web ID:2363Minimum Order: 4+Availability: 45 In Stock Ships 2-3 weeks

- Total Height: 18.5 Feet

- Height Above Grade: 15 Feet

- Buried Depth Below Grade: 3.5 Feet

- Material: Fiberglass

- Pole Weight: 51 lbs

- Pole Width: 4 Inches

- Pole Finish: Fluoropolymer Coating

- Pole Color: Bronze | Black | White | Gray | Custom

- Pole Gauge: .205 in

- Pole Installation: Direct Burial

- Includes: Top Cap

- Warranty: 7 years

Starting At$698.56 - SKU:MLLG-WL-POLE-20FT-6-TRD-BZ-TN | Web ID:2169Minimum Order: 2+Availability: 12 In Stock Ships 7-14 Days

- Total Height: 20 Feet

- Material: Steel

- Pole Weight: 123 lbs

- Pole Width: 6 In at Base / 3 In

- Pole Bolt Circle: 9 to 11 Inches

- Pole Finish: Hot Dip Galvanized and Powder Coated

- Pole Color: Bronze

- Pole Gauge: 11

- Bolt Projection: 3.15 in

- Pole Installation: Anchor Base

- Warranty: 1 year

Starting At$767.31 - SKU:LLS-LP-POLE-FG163-20-AB-BZ | Web ID:2342Minimum Order: 4+Built to Order 8 Weeks

- Total Height: 20 Feet

- Material: Fiberglass

- Pole Weight: 85 lbs

- Pole Diameter: 6 in Base | 5.3 in Tip

- Pole Bolt Circle: 8 to 9.5 Inches

- Pole Finish: Acrylic Enamel

- Pole Color: Bronze | Custom

- Bolt Projection: 2.75 in

- Pole Installation: Anchor Base

- Bolt Size: 3/4 in x 24 in w / 3 in leg | 4 in thread

- Warranty: 15 years

Starting At$1,487.93 - SKU:LLS-LP-POLE-FG163-20-DB-BZ | Web ID:2344Minimum Order: 4+Built to Order 8 Weeks

- Total Height: 25 Feet

- Height Above Grade: 20 Feet

- Buried Depth Below Grade: 5 Feet

- Material: Fiberglass

- Pole Weight: 80 lbs

- Pole Diameter: 6 in Base | 5.3 in Tip

- Pole Finish: Acrylic Enamel

- Pole Color: Bronze | Custom

- Pole Installation: Direct Burial

- Warranty: 15 years

Starting At$1,224.14 25 Foot Round Tapered Steel Light Pole | 6.5 Inch Base Diameter | Anchor Base | High Wind Zone Rated

SKU:MLLG-WL-POLE-25FT-65-TRD-BZ-T | Web ID:2170Minimum Order: 2+Availability: 29 In Stock Ships 7-14 Days- Total Height: 25 Feet

- Material: Steel

- Pole Weight: 163 lbs

- Pole Diameter: 6.5 In Base | 3 In Tip

- Pole Bolt Circle: 9 to 11 Inches

- Pole Finish: Hot Dip Galvanized and Powder Coated

- Pole Color: Bronze

- Pole Gauge: 11

- Bolt Projection: 3.15 in

- Pole Installation: Anchor Base

- Warranty: 1 year

Starting At$1,008.00- SKU:LLS-LP-POLE-FG163-25-DB-BZ | Web ID:2345Minimum Order: 4+Built to Order 8 Weeks

- Total Height: 30 Feet

- Height Above Grade: 25 Feet

- Buried Depth Below Grade: 5 Feet

- Material: Fiberglass

- Pole Weight: 90 lbs

- Pole Diameter: 6 in Base | 5.3 in Tip

- Pole Finish: Acrylic Enamel

- Pole Color: Bronze | Custom

- Pole Installation: Direct Burial

- Warranty: 15 years

Starting At$1,805.17 - SKU:LLS-LP-POLE-FG163-25-AB-BZ | Web ID:2343Minimum Order: 4+Built to Order 8 Weeks

- Total Height: 25 Feet

- Material: Fiberglass

- Pole Weight: 104 lbs

- Pole Diameter: 6 in Base | 5.3 in Tip

- Pole Bolt Circle: 8 to 9.5 Inches

- Pole Finish: Acrylic Enamel

- Pole Color: Bronze | Black | White | Gray | Custom

- Bolt Projection: 2.75 in

- Pole Installation: Anchor Base

- Warranty: 15 years

Starting At$1,939.66 - SKU:MLLG-WL-POLE-30FT-7-TRD-BZ-TN | Web ID:2171Minimum Order: 2+Out of Stock

- Total Height: 30 Feet

- Material: Steel

- Pole Weight: 300 lbs

- Pole Diameter: 7 in Base | 3 in Tip

- Pole Bolt Circle: 9.8 to 11.4 Inches

- Pole Finish: Hot Dip Galvanized and Powder Coated

- Pole Color: Bronze

- Pole Gauge: 7

- Bolt Projection: 3.15

- Pole Installation: Anchor Base

- Warranty: 1 year

Starting At$1,498.00 - SKU:LLS-WG-POLE-CP-45-12RD-[color]-DB | Web ID:2210Minimum Order: 4+Availability: 66 In Stock Ships 2-3 weeks

- Total Height: 45 Feet

- Height Above Grade: 38 Feet

- Buried Depth Below Grade: 7 Feet

- ANSI Class: Class 2

- Material: Fiberglass

- Pole Weight: 760 lbs

- Pole Diameter: 11.85 inches

- Pole Finish: Fluoropolymer Coating

- Pole Color: Bronze | Black | White | Gray | Custom

- Pole Gauge: .532 in

- Pole Installation: Direct Burial

- Warranty: 7 years

Starting At$4,916.67

What is a High-Wind Light Pole?

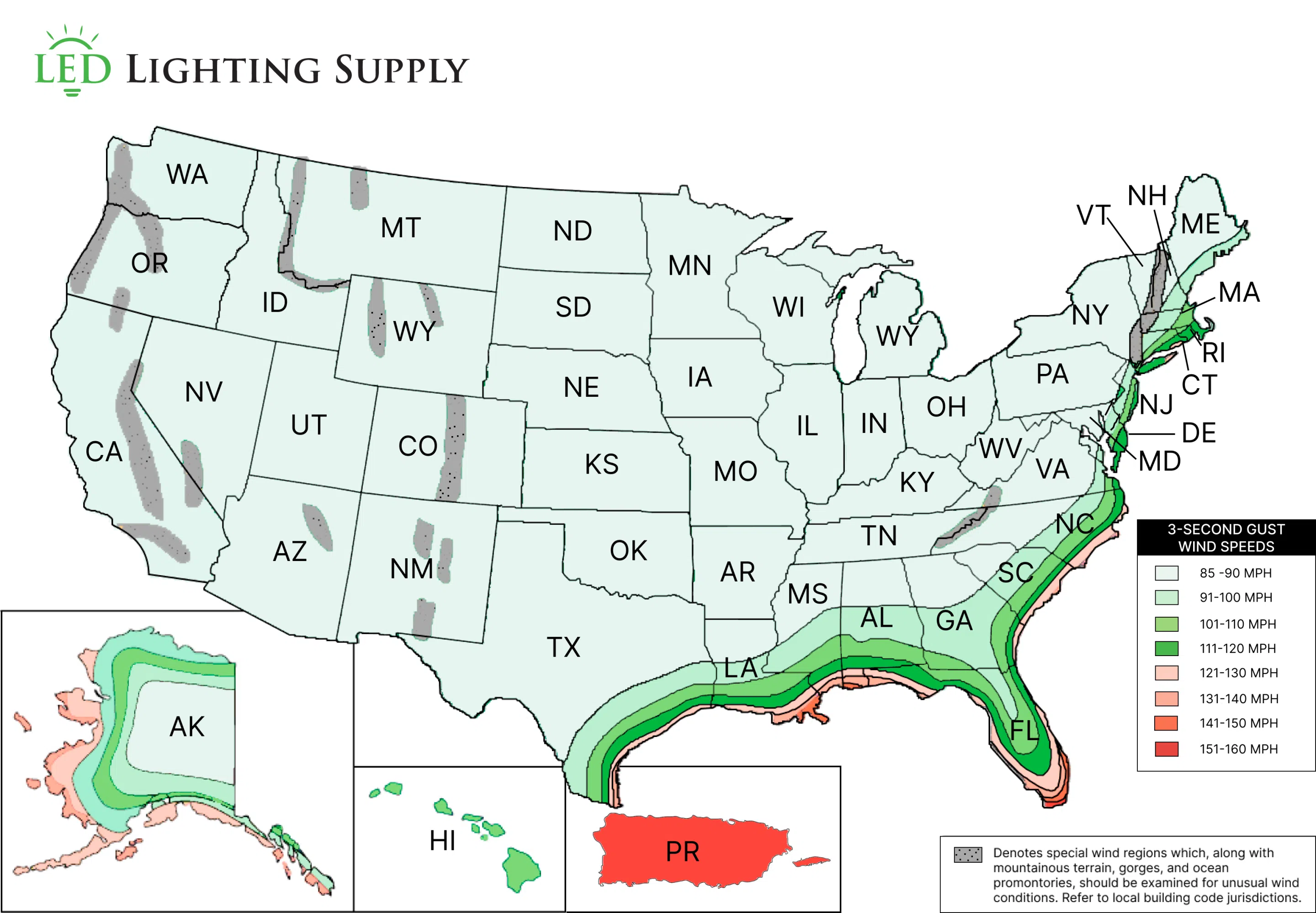

High-wind-rated light poles are engineered to withstand extreme wind forces that can damage or destroy standard poles. After 15+ years of outdoor lighting installations, we know proper wind rating is critical in coastal, plains, and hurricane-prone areas. Our high-wind poles feature reinforced construction and strong EPA ratings of 150+ mph, maintaining structural integrity when specified for severe weather. The engineering focuses on wind resistance while keeping your lighting system functional.

What Are EPA Wind Speed Ratings?

A light pole's Effective Project Area (EPA) measures wind resistance by calculating the surface area exposed to wind at specific speeds. EPA ratings account for the total wind load on the pole and all mounted components, including fixtures, arms, and hardware. Most commercial projects require EPA ratings between 6-12 square feet, with coastal sites often needing higher ratings. EPA requirements depend on pole height, fixture quantity, arm extensions, and local wind conditions.

Consult regional building codes since wind zones vary significantly by location - verify requirements with your local authority. Taller poles have higher EPA ratings due to more surface exposure, while tapered designs reduce wind resistance compared to straight poles. Proper EPA selection helps prevent failure and protects property and people when poles are engineered and installed correctly.

What Materials Are Best for High-Wind Light Poles?

Fiberglass composite poles often perform well in high-wind coastal environments compared to steel alternatives. Composite construction allows natural flex during wind events, reducing stress fractures depending on model and site. Fiberglass is recommended for saltwater areas, industrial zones with chemical exposure, and regions with frequent severe weather.

Steel poles with hot-dip galvanizing offer strength for inland high-wind sites when specified correctly. The galvanized coating resists corrosion and maintains structural integrity under heavy loads. Fiberglass poles resist rot, rust, corrosion, and fire, extending service life in challenging environments, though results vary by installation.

Can I Mount Multiple Fixtures on a High-Wind Rated Pole?

Multiple fixtures can be mounted on EPA-rated poles, but each fixture increases total wind load. Street lights, area floods, and decorative fixtures all add to the EPA requirement. Multi-fixture installations often use shorter arm extensions and strategic positioning to minimize wind exposure.

Balance fixture quantity with pole height and local wind conditions. Most high-wind installations support 2-4 fixtures, depending on fixture size and mounting configuration. Compact LED fixtures create less wind resistance than traditional shoebox designs, allowing more fixtures per pole when properly calculated.

How Do I Calculate High Wind Loads for a Light Pole?

Our calculator determines wind loads and fixture capacity for your installation. Enter your pole height, fixture specs, and local wind zone data to get EPA requirements. This calculation is essential for coastal parking lots, airports, and highway lighting where wind exposure is severe.

How Can I Prevent High-Wind Poles From Falling or Bending?

Proper foundation design is crucial for high-wind installations and must be engineered for the site. We recommend anchor bolt foundations extending 6-8 feet deep for most applications, though soil and pole height may require deeper foundations. The foundation must handle both vertical loads and overturning moments from wind.

Material selection impacts wind resistance. Tapered poles distribute wind loads better than straight poles, and breakaway bases add safety in extreme conditions. Regular inspection of anchor bolts, base connections, and structure helps identify issues before failure. Installing poles with EPA ratings above local requirements adds safety margin for unexpected weather.

Why Choose LED Lighting Supply for High-Wind Light Poles?

Our engineering team provides custom lighting layouts to optimize pole placement and minimize wind exposure while maximizing coverage. We calculate energy savings based on your current fixtures and utility rates, showing projected ROI timelines - results vary by installation.

Our product specialists have specified high-wind poles for hundreds of coastal facilities, airports, and hurricane-zone sites. We work directly with pole manufacturers to ensure you receive the EPA ratings and certifications required for your wind zone. We verify all calculations and specifications before shipping to help prevent costly field modifications or structural failures.

High Wind Rated Light Poles Frequently Asked Questions

What is a High-Wind Light Pole?

High-wind-rated light poles are engineered to withstand extreme wind forces that would damage standard poles, featuring reinforced construction and EPA ratings of 150+ mph. These poles are specified for coastal areas, plains regions, and hurricane-prone zones where structural integrity under severe weather is required.

What Are EPA Wind Speed Ratings?

Effective Project Area (EPA) quantifies wind resistance by measuring surface area exposed to wind forces, calculating total wind load on the pole and all mounted components including fixtures, arms, and hardware. Most commercial projects require EPA ratings between 6-12 square feet, though coastal installations often demand higher ratings - verify requirements with your local government authority since wind zones vary significantly across geographic areas.

How Do I Calculate High Wind Loads for a Light Pole?

Use our maximum wind speed calculator to determine exact wind loads and fixture capacity by inputting your pole height, fixture specifications, and local wind zone data. This calculation is essential for coastal parking lots, airport lighting, and highway applications where wind exposure is severe.

What Materials Are Best for High-Wind Light Poles?

Fiberglass composite poles offer natural flex during wind events and provide rot, rust, corrosion, and fire resistance for saltwater exposure areas and regions with frequent severe weather. Steel poles with hot-dip galvanizing provide excellent strength for inland high-wind applications while resisting corrosion under extreme loads.

Can I Mount Multiple Fixtures on a High-Wind Rated Pole?

Multiple fixtures increase total wind load calculation, with most high-wind installations accommodating 2-4 fixtures depending on fixture size and mounting configuration. Compact LED fixtures create less wind resistance than traditional shoebox designs, and shorter arm extensions help minimize wind exposure.

How Can I Prevent High-Wind Poles From Falling or Bending?

Anchor bolt foundations extending 6-8 feet deep are recommended for most high-wind applications, though soil conditions and pole height may require deeper installations. Tapered poles distribute wind loads more effectively than straight poles, and installing poles with EPA ratings exceeding local requirements provides additional safety margins.

Why Choose LED Lighting Supply for High-Wind Light Poles?

Our engineering team provides complimentary custom lighting layouts that optimize pole placement for coverage efficiency, and we verify all calculations and specifications before shipping. We maintain direct relationships with pole manufacturers to ensure you receive the exact EPA ratings and certifications required for your project''s wind zone.