How to Choose LED High Bay Lights

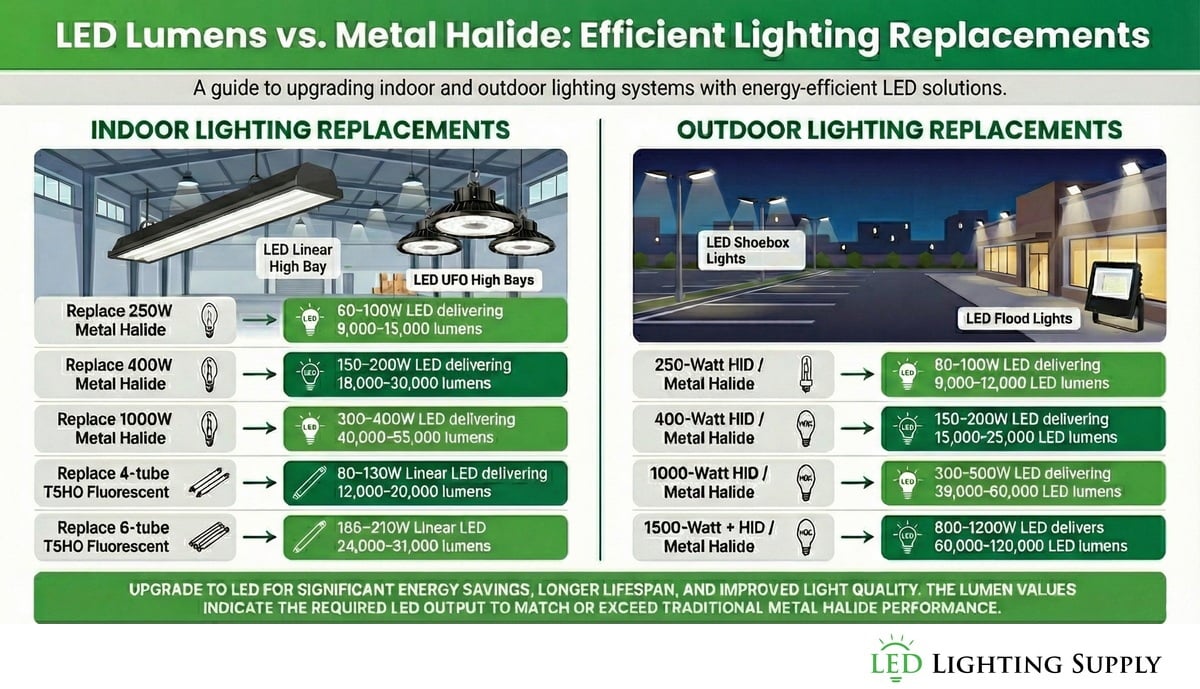

Industrial and commercial facilities struggling with outdated metal halide and high-pressure sodium lighting now have access to proven LED high bay technology that delivers consistent performance while reducing energy consumption by up to 70%. After over 15 years in the commercial lighting industry, LED Lighting Supply has witnessed this transformation across thousands of installations, from manufacturing plants to aircraft hangars.

The U.S. Department of Energy’s comprehensive analysis of LED lighting in industrial applications confirms that LED high bay systems can reduce energy consumption by 50-70% compared to conventional metal halide and high-pressure sodium fixtures, while providing superior light quality and significantly longer operational life in demanding industrial environments.

Our customers frequently report the immediate impact they notice after upgrading to modern LED high bay fixtures, which deliver 130-180 lumens per watt, compared to traditional metal halide systems that typically struggle to reach 90 lumens per watt. LED Lighting Supply’s expertise ensures you receive maximum efficiency and performance from every fixture installation.

Who Is this Guide For?

This guide is intended for facility managers, engineers, contractors, and operations teams responsible for specifying or upgrading LED high bay lighting in warehouses and industrial facilities.

High Bay Lighting Selection Checklist

Choosing the correct LED high bay fixture requires more than simply selecting a wattage or matching an existing metal halide fixture. After designing thousands of high bay lighting layouts, we use the checklist below to ensure proper light levels, uniformity, and long-term performance in warehouses and industrial facilities.

- Target Foot-Candle Levels by Application: Required light levels vary by task.

- Lumens Required (Not Wattage): LED high bay selection should always be based on delivered lumens.

- Ceiling Height & Mounting Height: Determine the mounting height before selecting lumens or optics.

- Beam Angle & Optic Selection: Proper optic selection prevents light loss and improves uniformity.

- Fixture Type: UFO vs Linear High Bays: Fixture form factor impacts durability and distribution.

- Voltage, Dimming & Control Compatibility: Confirm voltage and control requirements early.

- Color Temperature & CRI Requirements: Color temperature affects visibility and comfort.

- Environmental & Impact Ratings: IP and IK ratings prevent premature failure.

- Special Application Requirements: Identify high-temp, food-safe (NSF), and hazardous location needs before selecting fixtures.

Important: Skipping any of these steps is the leading cause of uneven lighting, glare, and costly retrofits.

Case Study: Replacement of 1500 Watt Metal Halide Lighting with 480 Watt LED UFO High Bays in Lagos, Nigeria

| After: 480 Watt LED UFO High Bay Light | 76800 Lumens |

|

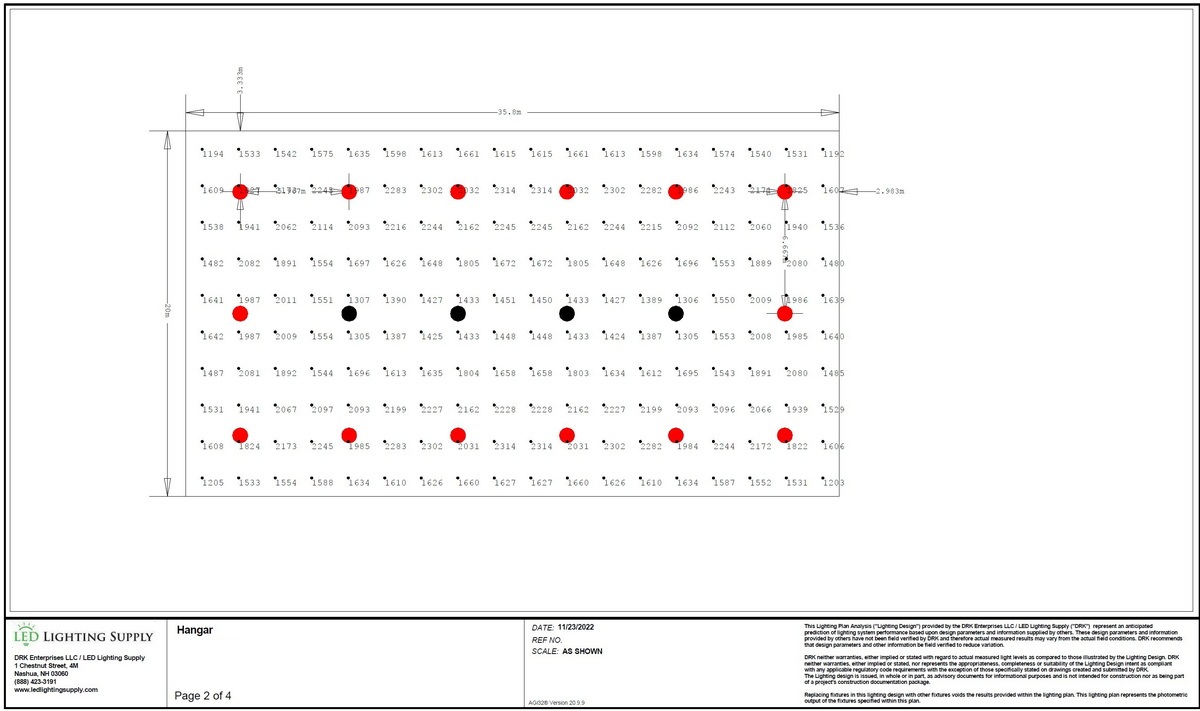

Lighting Plan We Created for the Customer

|

Lighting Plan |

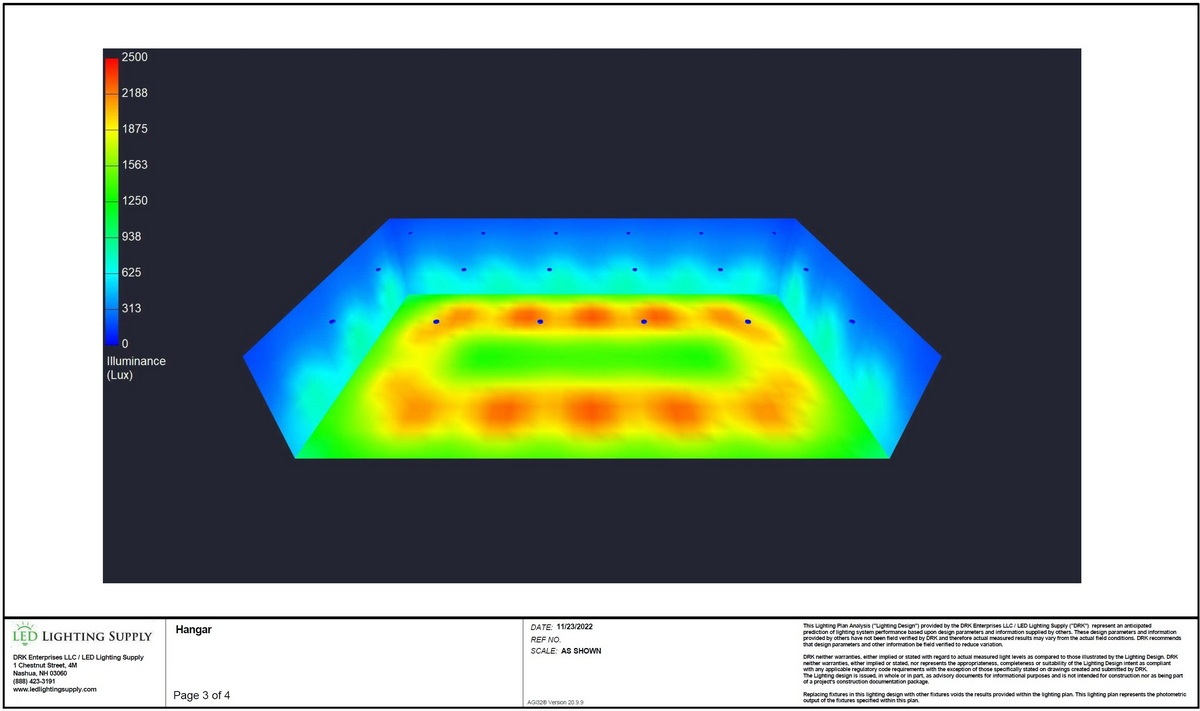

Heat Map |

|

|

Aircraft Hangar Lighting Installation Plan Metrics

- Mounting height: 35 ft ft

- Fixtures Used: MLLG-LED-HB5-480-5-60: 480 Watt LED UFO High Bay | 76800 Lumens | 5000K | 100-277V

- FC achieved: 167 FC average

- Uniformity (Avg/Min): 1.51

Case Study: Conversion of (72) T5 6 tube fixtures to LED Lighting Supply 200 Watt LED UFO Fixtures (one-for-one replacement) in Williston, ND

|

Before: T5 54W HO Fluorescent Fixtures |

After: 200 W LED UFO Fixtures |

|

|

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

LED High Bays Warehouse Installation Lighting Plan Metrics

- Mounting height: 20 ft

- Fixture Used: MLLG-LED-HBC-200-5-120: 100 / 120 / 150 / 200 Watt Adjustable LED UFO High Bay | 15000 to 30000 Lumens | 5000K | 100-277V | White Housing

- FC achieved: 60.33 FC average

- Uniformity (Avg/Min): 1.42

Case Study LED High Bays Warehouse Installation Energy Savings: 200W LED vs 324W Fluorescent Replacement (with ballast)

Assumptions: Based on 18 hours/day, 300 days/year at $0.08/kWh

| Fluorescent (373W) | Annual Energy Cost: $160.96 5 Year Energy Cost: $804.82 5 Year Savings: $0.00 |

| LED UFO Fixture (200W) | Annual Energy Cost: $86.40 5 Year Energy Cost: $432.00 5 Year Savings: $26,842.75 |

| Savings & Payback | Single Fixture Annual Savings: $74.56 72 Fixture Annual Savings: $5369 ROI Timeline: Under 19 months |

| Performance Summary | Energy Reduction: 46% 5-Year ROI: 22,648% Lamp Life: 50,000+ (LED) vs 30,000 (fluorescent) |

Professional Lighting Design Eliminates Project Risk

Our Product Specialists understand that successful high bay installations begin with comprehensive lighting plans that eliminate costly guesswork. We’ve found that facilities utilizing proper lighting design achieve optimal results while avoiding common pitfalls, such as inadequate illumination or energy waste. Storage areas typically require 30 foot-candles, while warehouses need 50 foot-candles and assembly zones demand 70+ foot-candles for safe, productive operations.

The Illuminating Engineering Society (IES) provides detailed guidance on workplace illumination levels through its recommended practices, which specify minimum lighting requirements for different industrial and commercial applications. IES recommended practices for industrial lighting help ensure optimal visibility and safety while maintaining energy efficiency in high bay installations.

Determining Precise Fixture Requirements

With over 15 years of experience completing lighting assessments across diverse industrial applications, our team provides complementary lighting design services that calculate exact fixture quantities, positioning, and performance metrics for your specific space. We map light distribution patterns and identify precise wattage requirements for uniform illumination, from aircraft hangars requiring 100+ foot-candles to cold storage facilities with unique mounting challenges.

Recommended Foot-Candle Levels for High Bay Applications

Target foot-candle levels are one of the most critical inputs when designing an LED high bay lighting system. Foot-candles measure the amount of usable light reaching the working surface, not just what the fixture produces. Selecting the correct target ensures safety, productivity, and long-term visual comfort.

The recommended ranges below reflect common industry practices and align with Illuminating Engineering Society (IES) guidelines. Final requirements may vary based on task complexity, ceiling height, surface reflectivity, and local codes.

Common High Bay Foot-Candle Targets by Application

- Bulk storage / inactive warehouse areas: 20-30 foot-candles

- General warehouse operations: 40-50 foot-candles

- Picking and packing areas: 50-70 foot-candles

- Assembly lines (general): 60-80 foot-candles

- Assembly lines (fine detail): 80-100+ foot-candles

- Manufacturing floors: 50-75 foot-candles

- Machine shops: 70-100 foot-candles

- Quality control & inspection stations: 100+ foot-candles

- Aircraft hangars (general service): 75-100 foot-candles

- Aircraft hangars (maintenance & inspection): 100-150 foot-candles

- Automotive service bays: 80-100 foot-candles

- Fabrication and welding areas: 70-90 foot-candles

- Cold storage facilities: 40-60 foot-candles

- Food processing facilities: 70-100 foot-candles

- Packaging and labeling areas: 60-80 foot-candles

- Gymnasiums and indoor sports courts: 50-75 foot-candles

- Distribution centers: 40-60 foot-candles

- Loading docks: 30-50 foot-candles

- Equipment maintenance areas: 70-100 foot-candles

- High-bay retail (warehouse-style stores): 50-75 foot-candles

- Paint booths and finishing areas: 100+ foot-candles

Important: Higher foot-candle targets do not automatically mean higher wattage fixtures. Proper beam angle selection, fixture spacing, mounting height, and surface reflectivity all play a significant role in achieving these targets efficiently.

Because foot-candle requirements vary widely by application, a photometric lighting plan is the most reliable way to confirm that your space meets recommended illumination levels without over-lighting, glare, or wasted energy.

Focus on Light Output Performance Over Input Wattage

Our customers frequently tell us they initially approach projects thinking about wattage requirements, but LED Lighting Supply’s expertise ensures you focus on delivered lumens for optimal results. Understanding your required illumination levels drives every subsequent decision about beam angles, fixture spacing, and mounting heights.

Never begin this process by assuming you need a high bay fixture with a specific wattage.

We’ve found that facilities using proper lumen calculations achieve better uniformity and energy efficiency. Ceiling height directly correlates to lumen requirements, but building layout and reflective surfaces also influence these calculations.

Ceiling Height & Mounting Height Considerations

Ceiling height and mounting height are the foundation of selecting the proper LED high bay. Before determining lumens, beam angles, or fixture type, you must first confirm how high the fixtures will be installed above the working surface.

LED high bay lights are typically used in spaces with ceilings ranging from 20 to 60 feet. As mounting height increases, higher lumen output and narrower beam angles are required to ensure sufficient light reaches the floor without excessive loss or glare.

As a general guideline, fixture spacing should closely align with mounting height. For example, fixtures mounted at 25 feet are often spaced approximately 25 feet apart. While these rules of thumb are helpful, a photometric lighting plan is the most reliable way to confirm proper spacing, uniformity, and target foot-candle levels.

If your ceiling height is below 20 feet, LED low bay lights may be more appropriate. For a detailed comparison, see our guide on LED High Bays vs LED Low Bay Lighting.

Select the Optimal Form Factor for Your Application

Two primary fixture designs address different installation requirements and environmental conditions. Our Product Specialists understand that linear panel fixtures excel for fluorescent system replacements, while UFO Round fixtures provide superior performance for challenging industrial environments previously served by metal halide systems.

- Linear high bays deliver exceptional results for fluorescent retrofits in spaces up to 30 feet high, offering broad light distribution without requiring optical accessories.

- UFO Round fixtures excel in demanding environments up to 100 feet high, featuring robust construction, precise beam control through interchangeable optics, and IP65+ weatherproof ratings.

UFO LED High Bay Lights

UFO fixtures provide exceptional durability for demanding industrial environments where traditional lighting fails. Their compact, circular design houses high-performance LEDs behind precise optical systems, delivering controlled beam patterns from 30 to 120 degrees. We engineer solutions that withstand impact, moisture, and temperature extremes while maintaining consistent performance.

Most customers choose LED warehouse lights and LED gymnasium lights where durability and performance are non-negotiable.

- Wattage Options: 100 Watts to 600 Watts

- Lumens: 13,000 to 96,000

- Efficiency Ratings: 130 to 180 lumens per watt

- Replaces: 250-Watt to 2000-Watt Metal Halide

- Optimal Color Temperatures: 4000K or 5000K

- CRI: 70+

- IP Rating (Wet): IP65

- Voltages: Standard = 100V-277V. High = 277V-480V (on select models only)

- Impact Ratings: IK08 or above

- Mounting Options: Eye hook (most common) and Pendant

- Surge Protection: Available

- Motion Sensors: Available

Linear LED High Bay Lights

Linear fixtures excel in controlled indoor environments where wide, even light distribution takes priority over focused beam control. These panel-style units replace multiple T5 or T8 fluorescent fixtures while delivering superior light quality and energy efficiency. LED Lighting Supply’s expertise ensures optimal results in clean, dry facilities with moderate ceiling heights where uniform illumination is the primary objective.

- Wattage Options: 80 Watts to 500 Watts

- Lumens Range: 11,000 to 42,000

- Efficiency Ratings: 135 to 140 lumens per watt

- Replaces: 4 to 8 tube T5 54-Watt HO

- Optimal Color Temperatures: 4000K or 5000K

- CRI: 70+

- IP Rating (Wet): On select models only.

- Voltages: Standard = 100V-277V. High = 277V-480V (on select models only)

- Rating for Impact: On select models only.

- Mounting Options: Pendant, Cable Mount, and Ceiling Mount

- Surge Protection: Available

- Motion Sensors: Available

Understanding Light Distribution Differences

Physical design differences create distinct light distribution characteristics that impact installation success. Linear fixtures distribute LEDs across rectangular surfaces measuring several feet in length, naturally producing broad, even illumination patterns ideal for lower mounting heights. UFO fixtures concentrate high-power LEDs within 12-15 inch diameter housings, enabling precise optical control through interchangeable lenses for challenging applications.

Our Product Specialists understand that installations above 30 feet require focused beam angles from UFO fixtures to maintain light intensity at working levels more effectively than the dispersed output from linear fixtures. Conversely, linear fixtures provide superior uniformity for lower mounting heights where broad coverage enhances workplace safety and productivity.

Maximize Long-Term Savings Through High-Efficacy Technology

Efficacy measures how effectively fixtures convert electrical input into visible light output, expressed as lumens per watt. We’ve found that facilities using high-efficacy fixtures generate substantial energy savings over their 50,000+ hour lifespan that quickly justify any additional upfront investment through reduced operating costs. LED Lighting Supply’s expertise ensures you understand this crucial comparison between two fixtures producing identical illumination:

- A 100-Watt fixture at 150 lumens/watt produces 15,000 lumens.

- A 150-Watt fixture at 100 lumens/watt also produces 15,000 lumens.

- The more efficient fixture saves 50 watts per hour of operation, translating to thousands in reduced energy costs.

Premium fixtures typically offer 150-180 lumens per watt efficacy, while budget options may only achieve 100-120 lumens per watt. With over 15 years of experience, we’ve consistently seen the energy savings from higher-efficacy fixtures easily justify their modest price premium.

Electrical Compatibility Made Simple

Commercial and industrial facilities typically operate on electrical systems ranging from 100 to 480 volts. Modern LED drivers automatically detect and adapt to incoming voltage within their specified range, eliminating installation complexity and ensuring reliable performance. Standard driver configurations accommodate most applications:

- 100V-277V (Standard – included in the cost of the fixture)

- 277V-480V (High Voltage Option)

- 347V-480V (Another less common high-voltage option)

Optimize Visual Performance Through Proper Color Temperature Selection

Color temperature selection impacts both visual comfort and task performance in ways that directly affect productivity and safety. Our customers frequently tell us about improved worker alertness and reduced eye strain after upgrading to properly selected color temperature solutions. These measurements use the Kelvin scale, where higher numbers indicate cooler, bluer light and lower numbers represent warmer, yellower illumination.

- 4000K provides a balanced white light ideal for commercial spaces and fluorescent retrofit applications

- 5000K delivers crisp, daylight-quality illumination perfect for industrial environments and metal halide replacement projects

LED Lighting Supply’s expertise shows that over 90% of our industrial customers choose 5000K for its superior visibility and alertness benefits, with the remaining 10% selecting 4000K for softer commercial environments where visual comfort takes priority.

Enhance Color Accuracy with Appropriate CRI Selection

Color Rendering Index quantifies how accurately light sources reveal true colors compared to natural sunlight, directly impacting visual performance and worker effectiveness. Higher CRI values enable better color discrimination and reduced eye strain during detailed work, improving both safety and productivity.

- Commercial LED lighting and industrial LED lighting perform exceptionally well with CRI 70+ fixtures

- Precision work areas, quality control stations, and finishing operations benefit from CRI 80+ for enhanced color accuracy and improved inspection capabilities

Our Product Specialists understand that better light quality reduces the quantity of fixtures needed for adequate visibility. We’ve found that facilities using proper CRI specifications achieve excellent results with CRI 70 for general applications, while specialized tasks may warrant higher color rendering performance for critical visual tasks.

Reduce Operating Costs with Intelligent Motion Control

Occupancy sensors and lighting controls can reduce energy consumption by 30-50 percent in facilities with intermittent use patterns, creating substantial savings that compound over years of operation. Two primary sensor technologies address different detection requirements based on your facility’s specific usage patterns:

- Microwave sensors excel at detecting movement across large areas, making them ideal for warehouses and manufacturing floors with diverse activity patterns

- PIR (Passive Infrared) sensors respond to heat signatures within smaller detection zones, suitable for offices and break rooms with predictable occupancy

Motion sensor integration requires fixtures equipped with 0-10V dimmable drivers that enable smooth dimming transitions from full brightness to reduced standby levels. Without dimmable capability, sensors can only provide basic on/off switching functionality that may cause premature LED degradation. LED Lighting Supply’s expertise ensures you specify dimmable drivers during initial installation to future-proof your lighting system for advanced control integration and maximum energy savings potential

.

Flexible Mounting Solutions for Diverse Applications

Mounting flexibility accommodates diverse structural configurations and installation preferences while ensuring secure, long-lasting performance. We engineer solutions that work with existing infrastructure to minimize installation complexity and costs. Most high bay fixtures support multiple mounting methods:

- Eye hook mounting provides secure pendant installation from structural beams and existing mounting points

- Pendant systems offer adjustable height positioning for optimal light distribution

- Ceiling mount options work for direct attachment to solid surfaces and drop ceiling systems

- Suspended wire/cable mounting allows flexible positioning in challenging architectural spaces

Trunnion mounts, commonly associated with floodlighting, also work effectively for high bay installations requiring precise aiming adjustment for specialized applications.

Protect Your Investment with Proper Impact Ratings

Manufacturing environments, warehouses, and sports facilities face ongoing risks from flying objects, equipment contact, and accidental impacts that can damage standard fixtures and create safety hazards. Impact ratings, designated by IK codes from IK01 to IK10, indicate mechanical protection levels against physical impacts based on standardized testing protocols. Our Product Specialists understand that IK08+ ratings provide sufficient protection for most industrial applications, while IK10 represents maximum impact resistance for extreme environments with heavy machinery or high-velocity objects. Gymnasiums, loading docks, and material handling areas typically require these enhanced protection levels to prevent costly damage and safety incidents. UFO fixtures generally offer superior impact ratings compared to linear panels due to their robust construction and compact design, making them the preferred choice when physical durability is a priority.

High Bays for Special Applications

- If you have applications where the ambient temperature exceeds 150°F, then check out our product line of LED high temperature lights.

- If you need food-safe lighting, check out our LED NSF Certified Lights.

- If you are in a hazardous location where there is a risk of explosion from either gases, vapors, or dust, check out our product line of LED explosion-proof lights.

OSHA’s comprehensive guidance on electrical equipment in hazardous locations emphasizes the critical importance of proper fixture selection and installation. OSHA standards for hazardous (classified) locations require that lighting equipment be specifically designed and certified for the particular hazard classification to prevent ignition sources and maintain workplace safety.

Understand Your Electrical Load Reduction Benefits

Electrical load reduction represents one of LED conversion’s most significant long-term benefits beyond energy savings. Lower amperage requirements can defer costly electrical upgrades and free capacity for additional equipment or expansion projects.

Converting from 400 Watt Metal Halide to 150 Watt LED

Including ballast consumption, metal halide systems draw approximately 15% additional power beyond lamp rating, creating substantial load differences:

- Metal Halide: 460 Watts / 277 Volts = 1.66 Amps per fixture

- LED: 150 Watts / 277 Volts = 0.54 Amps per fixture

- Net reduction per fixture: 1.12 amps

Converting from 1000 Watt Metal Halide to 300 Watt LED

High-wattage metal halide conversions generate even more dramatic load reductions that can significantly impact electrical infrastructure requirements:

- Metal Halide: 1150 Watts / 277 Volts = 4.15 Amps per fixture

- LED: 300 Watts / 277 Volts = 1.08 Amps per fixture

- Net reduction per fixture: 3.07 amps

Quality Certifications and Compliance

All our fixtures carry essential certifications, including DLC Premium, UL Listed, and ETL Listed approvals that ensure safety, performance, and energy efficiency while qualifying your project for utility rebates and tax incentives. DLC Premium certification guarantees the highest efficiency standards and maximum rebate eligibility for cost-effective project implementation.

The Design Lights Consortium (DLC) sets rigorous performance standards for energy-efficient commercial lighting products, while Underwriters Laboratories (UL) provides critical safety testing and certification. DLC qualification ensures maximum utility rebate eligibility and energy efficiency performance, and UL Listed certification provides comprehensive safety assurance for electrical and fire safety compliance in commercial and industrial lighting installations.

Comprehensive USA-Based Warranty Support

All our lights come with at least a 5-year warranty, with all warranty support based in the USA for responsive service when you need it most. LED Lighting Supply’s expertise includes comprehensive customer support – we take warranty claims seriously and understand the importance of keeping your lighting operational. Our experienced support team works quickly to resolve any warranty issues and minimize downtime for your facility. Ready to transform your facility with proven LED high bay technology?

Request a free lighting plan from our specialists today and discover how modern LED solutions can reduce your energy costs while improving workplace safety and productivity.

Maximize Savings with Detailed Energy Analysis and Expert Guidance

Before purchasing LED high bay fixtures, understanding your projected energy savings eliminates guesswork and validates your investment decision. Our Product Specialists provide comprehensive energy savings calculations that detail exact consumption reductions, payback periods, and long-term cost benefits based on your current lighting system and utility rates. These calculations demonstrate how fixture selection affects annual operating costs, helping you choose the most cost-effective solution for your specific application. Additionally, our team delivers technical guidance on optimal fixture placement, beam angles, and control integration to ensure maximum performance from your new lighting system. Unlike suppliers that simply process orders, we combine decades of field experience with detailed photometric analysis to eliminate installation problems before they occur.