Showing 13–24 of 36 results

- SKU:LLS-X-HB8-310/270/240-CC | Web ID:2211Availability: 659 In Stock Ships 3-5 Days

- Watts: 240 | 270 | 310

- Lumens: 34800 | 39150 | 45000

- Lumens/Watt: 145

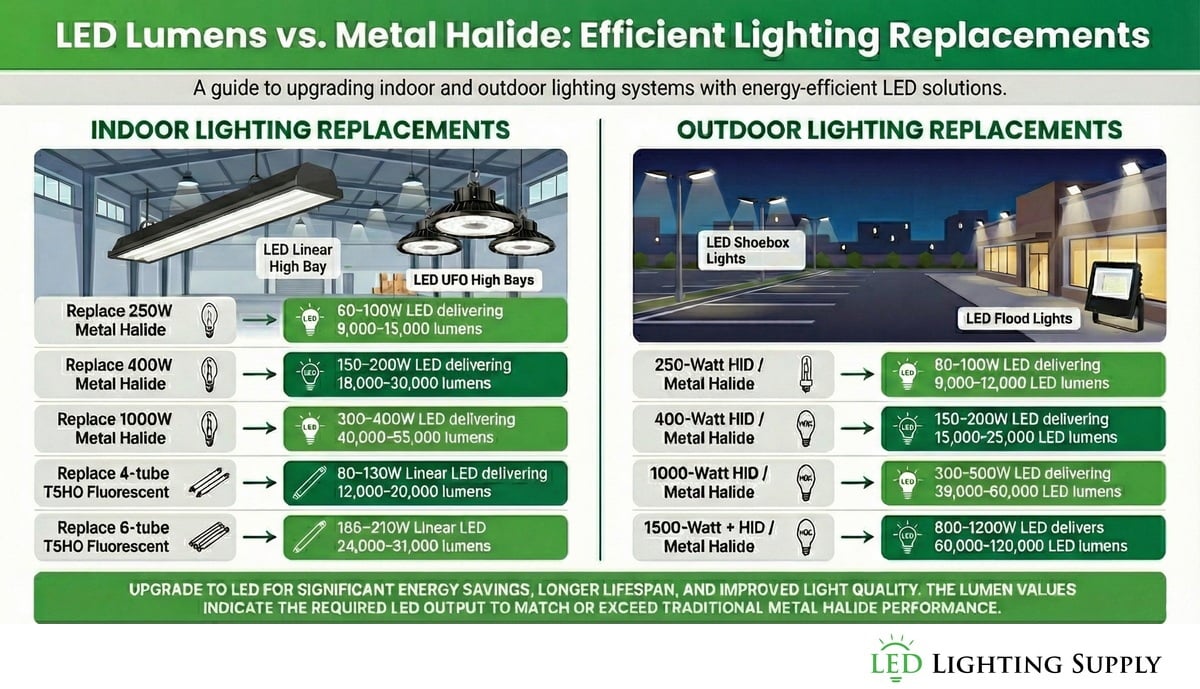

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 110°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Hook | Pendant

- Mount (Opt): Surface

- Dimensions: 14 x 11 Inches

- Cord Length: 5 Feet

- Weight: 11 lbs

Starting At$189.44 - SKU:LLS-X-HB9-320A-CC-[C] | Web ID:2594Black:627 In StockShips 3-5 DaysWhite:1074 In StockShips 3-5 Days

- Watts: 200 | 240 | 320

- Lumens: 30000 | 36000 | 48000

- Lumens/Watt: 150

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 110°

- Optics: Polycarbonate Lens

- Fixture Color: Black | White

- Mount: Hook

- Mount (Opt): Pendant | Surface

- Dimensions: 13.8 X 9.5 Inches

- Cord Length: 5 Feet

- Weight: 13 lbs

Starting At$196.00 - SKU:LLS-X-HB8-310-5-HV | Web ID:2214Availability: 121 In Stock Ships 3-5 Days

- Watts: 310

- Lumens: 45000

- Lumens/Watt: 145

- Replaces: 1000 | 1500 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 277V-480V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Hook

- Mount (Opt): Pendant | Surface

- Dimensions: 13.8 X 10.9 Inches

- Cord Length: 5 Feet

- Weight: 13 lbs

Starting At$246.15 - SKU:LLS-HB-500A-CC | Web ID:2663Availability: 83 In Stock Ships 2-3 Days

- Watts: 300 | 400 | 500

- Lumens: 44900 | 62000 | 79100

- Lumens/Watt: 155

- Replaces: 1500 | 2000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -22°F to 122°F

- Rated Life: 170,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook

- Dimensions: 17.7 D x 10.6 H

- Weight: 14.5 lbs

Starting At$475.73 - SKU:LLS-HB-500A-CC-HV | Web ID:2664Availability: 72 In Stock Ships 2-3 Days

- Watts: 250 | 375 | 500

- Lumens: 38700 | 58000 | 76800

- Lumens/Watt: 155

- Replaces: 1500 | 2000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 277V-480V

- Surge Protection: 10kV

- Operating Temp: -22°F to 122°F

- Rated Life: 150,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook | Yoke

- Dimensions: 19 D x 17 H

- Weight: 28 lbs

Starting At$644.84 - SKU:MLLG-LED-HB5-480-5-60 | Web ID:2025Availability: 96 In Stock Ships 2-3 Days

- Watts: 480

- Lumens: 76800

- Lumens/Watt: 160

- Replaces: 1500 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -22°F to 122°F 120-277V

- Rated Life: 244,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 60°

- Beam Angle (Opt): 10° | 30°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook

- Dimensions: 17.7 X 9.5 Inches

- Cord Length: 5 Feet

- Weight: 24 lbs

Starting At$399.42 - SKU:MLLG-LED-HB5-600-5-60 | Web ID:2027Availability: 45 In Stock Ships 2-3 Days

- Watts: 600

- Lumens: 96000

- Lumens/Watt: 160

- Replaces: 2000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -22°F to 113°F

- Rated Life: 244,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 60°

- Beam Angle (Opt): 10° | 30°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook

- Dimensions: 17.7 X 10.2 Inches

- Cord Length: 5 Feet

- Weight: 28.4 lbs

Starting At$472.85 - SKU:LLS-X-HBLIN8-2-105/90/80-CC | Web ID:2270Availability: 316 In Stock Ships 3-5 Days

- Watts: 80 | 90 | 105

- Lumens: 12000 | 13500 | 15750

- Lumens/Watt: 150

- Replaces: 150 | 250 | 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 113°F

- Rated Life: 100,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Frosted Lens

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 23.2 X 12.6 X 3 in

- Cord Length: No Cord

- Weight: 6.75 lbs

Starting At$143.27 - SKU:LLS-X-HBLIN8-2-165/140/130-CC | Web ID:2271Availability: 2750 In Stock Ships 2-3 Days

- Watts: 130 | 140 | 165

- Lumens: 19500 | 21000 | 24750

- Lumens/Watt: 150

- Replaces: 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 113°F

- Rated Life: 100,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Frosted Lens

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 23.2 X 12.6 X 3 in

- Cord Length: No Cord

- Weight: 6.75 lbs

Starting At$155.19 - SKU:LLS-X-HBLIN8-4-225/195/175-CC | Web ID:2272Availability: 2159 In Stock Ships 3-5 Days

- Watts: 175 | 195 | 225

- Lumens: 26250 | 29250 | 33750

- Lumens/Watt: 150

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 113°F

- Rated Life: 100,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Frosted Lens

- Fixture Color: White

- Dimensions: 44.3 X 12.6 X 3 in

- Cord Length: No Cord

- Weight: 11 lbs

Starting At$202.78 - SKU:LLS-X-HBLIN8-4-300/260/230-CC | Web ID:2273Availability: 2619 In Stock Ships 2-3 Days

- Watts: 230 | 260 | 300

- Lumens: 34500 | 39000 | 45000

- Lumens/Watt: 150

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 113°F

- Rated Life: 100,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Frosted Lens

- Fixture Color: White

- Mount: Chain-Cable

- Dimensions: 44.3 X 12.6 x 3 in

- Cord Length: No Cord

- Weight: 11 lbs

Starting At$213.64 - SKU:MLLG-X-LED-HBLIN6-90/105/130-CC | Web ID:2067Availability: 3343 In Stock Ships 3-5 Days

- Watts: 90 | 105 | 130

- Lumens: 13860 | 16170 | 20020

- Lumens/Watt: 150

- Replaces: 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 10kV

- Operating Temp: -40°F to 122°F

- Rated Life: 50,000 hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Polycarbonate Lens

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 14 X 11.5 X 2.1 in

- Cord Length: No Cord

- Weight: 6 lbs

Starting At$114.91

What Are LED High Bay Lights?

LED high bay lights are commercial fixtures designed for large indoor spaces with ceilings typically 20 feet or higher. They deliver high lumen output with engineered optics to provide bright, even illumination in warehouses, factories, gyms, aircraft hangars, and distribution centers. High bay lights are the most common LED commercial lights for indoor applications.

LED Lighting Supply Commercial and Industrial LED High Bay Lights

Facility upgrades from metal halide and fluorescent systems demand precise matching of ceiling height, lumen requirements, and beam patterns to avoid costly mistakes. Drawing from 15+ years of lighting experience in industrial and commercial settings, LED Lighting Supply's Product Specialists have developed proven methodologies that eliminate guesswork and deliver optimal performance for each unique application.

The U.S. Department of Energy reports that LED technology can reduce energy consumption by 75% compared to traditional lighting in commercial and industrial applications. Their research shows that proper LED high bay selection and installation techniques are critical factors in achieving maximum energy savings and operational efficiency in large indoor spaces.

Large Indoor Spaces-Warehouses & Distribution Centers. The customer selected our 300 Watt UFO Warehouse Light | 45,000 Lumens to achieve the required foot candle levels with balanced lighting distribution across the entire floor

Need help choosing? Read our Buyers Guide to LED High Bays (foot-candle targets, lumen planning, optics, and fixture selection).

Quick Selection Guide

- Fixture type: Use UFO high bays for open areas and HID replacement; use linear high bays for aisles, racking, and fluorescent replacement

- Ceiling height match: Verify lumen output and beam angle match your mounting height (general guidance: 120 deg for under 25 ft, 90 deg for 25-35 ft, 60 deg for 35+ ft)

- Foot-candle targets: Start with 20-30 fc for warehouse storage, 30-50 fc for aisles/distribution, 50-80 fc for manufacturing - confirm with photometric plan

- Voltage compatibility: Verify building electrical service (120-277V or 277-480V) and select a matching driver or universal option

- Environmental ratings: Check datasheet for IP/IK ratings, temperature range, and certifications required for your application

- Controls integration: Consider 0-10V dimming with motion sensors for an additional 30% energy savings in task-based zones

Tip: Improper fixture spacing leads to uneven distribution - plan spacing at roughly 1.2 to 1.5 times mounting height, then verify with photometric layout for larger projects.

Use When / Don't Use When

Use LED High Bays When

- Ceiling heights are 20 feet or higher - designed for large indoor spaces with adequate mounting height

- You need wide-area coverage - warehouses, distribution centers, manufacturing, gymnasiums, and aircraft hangars

- Replacing HID or fluorescent systems - direct retrofits can achieve 50-75% energy reduction with improved light quality

- Long operating hours justify LED investment - 50,000-100,000 hour life vs ~15,000 hours for metal halide reduces maintenance cycles

- Environmental conditions require durability - IP65-IP69K and IK08-IK10 ratings available for harsh conditions (model dependent)

Don't Use LED High Bays When

- Ceiling height is under 20 feet - consider low bay or architectural fixtures for lower mounting heights

- You need specialized beam control - sports lighting, outdoor flood applications, or precise accent lighting may require different fixture types

- Temperature extremes exceed fixture ratings - verify operating temperature range on datasheet for unconditioned or extreme environments

- Voltage doesn't match available drivers - confirm 120-277V or 277-480V compatibility before ordering

- Code requires specific emergency features - verify emergency backup integration and egress lighting compliance with a licensed professional

What We Verify Before You Order

We confirm

- Ceiling height and mounting method compatibility

- Required foot-candle levels for your application

- Building voltage (120-277V or 277-480V)

- Environmental requirements (temperature, IP/IK ratings)

- Controls integration needs (dimming, sensors, emergency backup)

If we provide a lighting plan, you will get

- Fixture count and spacing layout validated for your space

- Expected foot-candle distribution across work areas

- Energy savings calculations based on your operating hours and rates

Note: Guidance is general planning information. Final selection should be validated with a photometric plan and confirmed by a licensed professional when required for code- or safety-critical areas.

1. UFO vs Linear High Bay Lights: Choosing the Right Fixture Type for Your Project

UFO and linear high bays can both meet the same foot-candle targets, but they distribute light differently. Use the guide below to select the fixture style that matches your layout, glare requirements, and racking/aisle conditions.

UFO High Bay Lights

Best for open areas and strong downward throw. UFO fixtures are a common choice for general-purpose high bay lighting, especially when replacing metal halide in warehouses, gyms, and broad production spaces.

- Point-source distribution: Compact circular design concentrates light for strong downward delivery

- Great for open floor plans: Warehouses, distribution centers, gyms, and general manufacturing

- Common for HID retrofits: Frequently used for metal halide replacement projects

- Wide output range: 60-600W models available, up to 96,000 lumens (model dependent)

- Rugged options: Often available with IP65 and IK08-IK10 ratings (verify on datasheet)

- Optics flexibility: Field-adjustable 60 deg/90 deg/120 deg beam angles on select models (model dependent)

Linear High Bay Lights

Best for aisles, rows, and uniform coverage. Linear fixtures spread light across a longer source, which helps reduce striping and improve consistency over racks, production lines, and fluorescent-style layouts.

- Wide, even coverage: Rectangular profile distributes light across broader zones

- Ideal for aisles & racking: Often preferred for long rows and high-rack storage layouts

- Fluorescent-style replacements: Strong fit for strip/linear retrofit projects

- Output range: 80-500W options up to 76,900 lumens (model dependent)

- Consistent work-plane lighting: Great for production lines, assembly areas, and task-heavy zones

UFO vs Linear High Bays: Quick Decision Guide

| Choose UFO when ... | You're lighting open areas, replacing metal halide, or you need strong downward throw and flexible placement. UFOs are also a good fit when layouts change over time, and you want a versatile distribution pattern. |

| Choose Linear when ... | You're lighting aisles, racks, or production lines, replacing fluorescent-style fixtures, or you want smoother uniformity across rows. Linear fixtures are often easier to aim for long rectangular spaces. |

| Aisles & high racks | For narrow aisles and high-rack storage, linear is often preferred for consistent aisle coverage. UFOs can still work with the right optics and spacing, but are more likely to create brighter pools if not planned carefully. |

| Glare management | UFOs can feel glarier in open areas if mounted low or overpowered. Consider diffusers, reflectors, lower-watt packages, or adjusted optics when glare is a concern. Linear fixtures often appear visually softer because the light source is spread over a longer surface. |

| Environment & durability | Both styles can be built for demanding sites, but availability varies by model. Always verify the exact fixture's IP/IK ratings, temperature range, and mounting hardware on the datasheet for your environment. |

| Controls & sensors | Both styles commonly support 0-10V dimming, motion sensors, and photocells (model dependent). In aisle/racking layouts, occupancy sensors can be especially effective because traffic patterns are predictable. |

Best practice: Many facilities use a hybrid approach: UFO fixtures for open floor areas and linear fixtures for aisles and production lines. A photometric plan confirms spacing, optics, and expected foot-candles before ordering large quantities.

High Bay vs Low Bay Selector

Choose feet or meters: Leave blank if you just want bay type.Recommended Foot-Candle Levels and Lighting Requirements by High Bay Application

Use these general planning ranges to estimate target light levels by application. Final fixture selection and layout should be verified with a photometric plan, especially for safety- or code-critical areas.

Most Common High Bay LED Lighting Applications

| Application and Recommended High Bay Fixture | Recommended Foot-Candles | Typical Mounting Height |

|---|---|---|

Warehouse and Logistics Facilities |

||

Open Warehouse Storage - UFO High Bay LED |

20-30 fc | 25-40 ft |

High-Rack Warehouse Aisles - Linear High Bay LED |

30-50 fc | 25-40 ft |

Distribution Centers and Fulfillment Hubs - UFO or Linear High Bay |

30-50 fc | 25-40 ft |

Logistics Cross-Dock Facilities - UFO High Bay |

30-50 fc | 25-40 ft |

Industrial Warehouses with Mezzanines - UFO High Bay |

30-50 fc | 18-35 ft |

Big Box Retail and Warehouse Clubs - UFO or Linear High Bay |

30-50 fc | 20-35 ft |

Wholesale Cash and Carry Stores - UFO or Linear High Bay |

30-50 fc | 18-30 ft |

E-Commerce Fulfillment Warehouses - UFO or Linear High Bay |

30-50 fc | 25-40 ft |

Manufacturing and Industrial Facilities |

||

Manufacturing General Production Areas - UFO or Linear High Bay LED |

30-70 fc | 20-35 ft |

Precision Assembly Manufacturing Areas - UFO or Linear High Bay |

70-125 fc | 18-30 ft |

Industrial Inspection and Quality Control Areas - UFO or Linear High Bay |

100-150 fc | 18-28 ft |

Production Line Aisles - Linear High Bay |

50-80 fc | 20-35 ft |

Sports and Recreational Facilities |

||

Gymnasiums and School Sports Facilities - UFO High Bay |

50-80 fc | 25-40 ft |

Indoor Sports Arenas and Field Houses - UFO High Bay |

50-100 fc | 30-50 ft |

Fitness Centers and Training Facilities - UFO or Linear High Bay |

30-60 fc | 16-30 ft |

Indoor Horse Arenas and Riding Arenas - UFO High Bay |

20-40 fc | 20-35 ft |

Transportation and Service Facilities |

||

Aircraft Hangars - UFO High Bay |

30-80 fc | 35-60 ft |

Bus Garages and Fleet Maintenance Bays - UFO High Bay |

30-60 fc | 20-35 ft |

Auto Repair Shops and Service Bays - UFO High Bay |

50-100 fc | 14-25 ft |

Cold Storage and Food Processing Facilities |

||

Cold Storage Warehouses - UFO High Bay LED or Vapor Tight |

20-30 fc | 20-35 ft |

Freezer Rooms and Low Temperature Storage - UFO High Bay or Vapor Tight |

10-20 fc | 18-30 ft |

Food Processing and Packaging Areas - Vapor Tight High Bay LED |

50-100 fc | 18-30 ft |

Large Volume and Specialty Facilities |

||

Bulk Material Handling and Tall Silos - UFO High Bay |

20-40 fc | 40-80 ft |

Convention Centers and Exhibition Halls - UFO or Linear High Bay |

30-70 fc | 30-50 ft |

Harsh Industrial Non Classified Environments |

||

Recycling and Waste Processing Facilities - UFO High Bay with IK Rated Option |

20-40 fc | 25-45 ft |

Water and Wastewater Treatment Plants - UFO or Linear High Bay with IP Rated Option |

20-50 fc | 20-40 ft |

Paper Mills and Pulp Processing Facilities - UFO High Bay with IP Rated Option |

30-60 fc | 25-50 ft |

Steel Mills and Heavy Industrial Plants - UFO High Bay with IK Rated Option |

30-60 fc | 30-60 ft |

Oil and Gas Facilities Non Classified Areas - UFO High Bay |

30-60 fc | 30-60 ft |

2. Voltage and Adjustable Technology

Adjustable technology delivers maximum flexibility for post-installation optimization without fixture replacement:

- CCT selectable: 3000K / 4000K / 5000K via onboard switch (model dependent)

- Wattage selectable: adjust output post-install to fine-tune light levels (model dependent)

- Optics options: 60 deg / 90 deg / 120 deg for distribution control (model dependent)

- Voltage options: 120-277V and 277-480V drivers available (verify on spec sheet)

Based on customer feedback, adjustable high bay LED lights provide facilities with the greatest flexibility for achieving optimal conditions after installation completion.

Metal halide replacements typically benefit from 5000K for enhanced visibility, while fluorescent upgrades achieve the closest color matching with 4000K. Color-adjustable fixtures with onboard switches allow facilities to change temperature post-installation as needs evolve.

Gymnasiums & Sports Facilities-Even distribution for athletic activities using our wattage-adjustable LED gymnasium light with high impact IK08 ratings for ball strike protection

3. Integrated Controls, Backup, and Mounting Options

Advanced control integration addresses both performance optimization and safety compliance requirements:

- Motion-sensor compatibility with 0-10V or 1-10V dimming typically achieves an additional 30% energy savings in task-based zones

- Emergency battery backup (EMB) can support egress and emergency illumination requirements when properly specified and installed (requirements vary by facility and local code)

- Multiple mounting styles, including eye hook, pendant, surface, and chain/cable suspension, work with existing infrastructure

- Direct replacement capability maintains identical mounting patterns while reducing amp loads that avoid electrical panel upgrades

- Photocell integration delivers up to 25% additional energy savings, depending on facility conditions

OSHA standards for workplace lighting establish minimum illumination requirements to ensure worker safety and productivity. The agency's construction industry lighting standards specify that adequate emergency lighting systems must be available to provide safe egress during power outages, making battery backup systems a critical safety consideration for industrial facilities when properly specified.

4. Certifications and Warranties

Certifications and reliable warranty support provide facility managers with confidence in long-term performance:

- Safety certifications include UL Listed and ETL Listed approvals. DLC or DLC Premium listed models may qualify for utility rebates where available (rebate amounts vary by utility, region, and product listing)

- Standard 5-year warranties backed by US-based support, with responsive warranty handling and clear documentation requirements

The Design Lights Consortium (DLC) serves as the leading authority for commercial LED lighting quality and efficiency standards. Their Qualified Products List certification program ensures that LED fixtures meet performance criteria for energy efficiency, photometric performance, and reliability. Many utility rebate programs reference DLC listings (often DLC Premium), but requirements vary by program, region, and application. Always confirm rebate rules and match the fixture listing accordingly.

Our dedicated, US-based warranty team resolves issues promptly when they arise. Customer feedback consistently highlights our warranty response time as exceeding industry standards.

Why our LED High Bay Lights Outperform Traditional High Bays like Metal Halide and Fluorescent Lights

Performance Benefits & Certified Reliability

Upgrading from HID or fluorescent to LED high bays can improve efficiency, light quality, and maintenance cycles (results vary by operating hours and facility conditions):

- Energy reduction: commonly 50-75% vs HID; higher with controls (results vary by operating hours and facility conditions)

- Long life: 50,000-100,000 hours typical vs ~15,000 hours for metal halide

- Instant-on: full brightness immediately (no warm-up)

- Light quality: flicker-free, 80+ CRI options common (varies by model)

- Durability: IP65-IP69K and IK08-IK10 options for harsh environments (model dependent)

- Lower maintenance: fewer lamp/ballast replacements over service life

What are the Cost Savings and ROI When You Convert from Metal Halide to LED?

150W LED UFO High Bay vs 400W Metal Halide Replacement (with ballast)

Assumptions: Based on 24 hours/day, 365 days/year at $0.16/kWh,

100 fixture(s), and a 15% ballast factor applied to the metal halide wattage

(400W lamp + 15% ballast = ~ 460W input).

•

Energy cost and ROI calculations are based on energy savings only and assume an LED fixture cost of

$100.00 per fixture.

• Maintenance savings from reduced bulb and ballast replacements are not included

in these calculations.

| Metal Halide (460W per fixture) |

Annual Energy Cost (per fixture): $644.74 Annual Energy Cost (all 100 fixtures): $64,473.60 5 Year Energy Cost (all fixtures): $322,368.00 5 Year Savings (all fixtures): $0.00 |

| LED UFO High Bay (150W per fixture) |

Annual Energy Cost (per fixture): $210.24 Annual Energy Cost (all 100 fixtures): $21,024.00 5 Year Energy Cost (all fixtures): $105,120.00 5 Year Savings (all fixtures): $217,248.00 |

| Savings & Payback |

Single Fixture Annual Savings (energy only): $434.50 100 Fixture Annual Savings (energy only): $43,449.60 LED Fixture Project Cost (100 fixtures): $10,000.00 Simple Payback from Energy Savings Only: under 3 months |

| Performance Summary |

Energy Reduction: 67% 5-Year ROI (All Fixtures, Energy Only): 2,072% Lamp Life: 50,000+ (LED) vs 15,000 (MH) |

In this example with 100 fixture(s), total LED fixture investment is approximately $10,000.00, and estimated annual energy-only savings are $43,449.60. Simple payback based on energy savings alone is under 3 months. Maintenance savings from eliminating metal halide bulb and ballast replacements provide additional value throughout the fixture's 50,000-hour lifespan, but are not included in this ROI calculation.

Case Study: Conversion of (72) T5 6 tube fixtures to LED Lighting Supply 200 Watt LED UFO Fixtures (one-for-one replacement) in Williston, ND

|

Before: T5 54W HO Fluorescent Fixtures |

After: 200 W LED UFO Fixtures |

|

|

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

LED High Bays Warehouse Installation Lighting Plan Metrics

- Mounting height: 20 ft

- Fixture Used: MLLG-LED-HBC-200-5-120: 100 / 120 / 150 / 200 Watt Adjustable LED UFO High Bay | 15000 to 30000 Lumens | 5000K | 100-277V | White Housing

- FC achieved: 60.33 FC average

- Uniformity (Avg/Min): 1.42

Case Study LED High Bays Warehouse Installation Energy Savings: 200W LED vs 324W Fluorescent Replacement (with ballast)

Assumptions: Based on 18 hours/day, 300 days/year at $0.08/kWh

| Fluorescent (373W) | Annual Energy Cost: $160.96 5 Year Energy Cost: $804.82 5 Year Savings: $0.00 |

| LED UFO Fixture (200W) | Annual Energy Cost: $86.40 5 Year Energy Cost: $432.00 5 Year Savings: $26,842.75 |

| Savings & Payback | Single Fixture Annual Savings: $74.56 72 Fixture Annual Savings: $5369 ROI Timeline: Under 19 months |

| Performance Summary | Energy Reduction: 46% 5-Year ROI: 22,648% Lamp Life: 50,000+ (LED) vs 30,000 (fluorescent) |

Case Study: Conversion of 400 Watt metal halide lighting to LED Lighting Supply 160 Watt LED UFO High Bay at Tri-City College Prep in Prescott, AZ

|

Before: 400 Watt Metal Halide High Bays |

After: 160 Watt LED UFO High Bay | 26400 Lumens |

|

|

Lighting Plan We Created for the Customer

|

Lighting Plan |

|

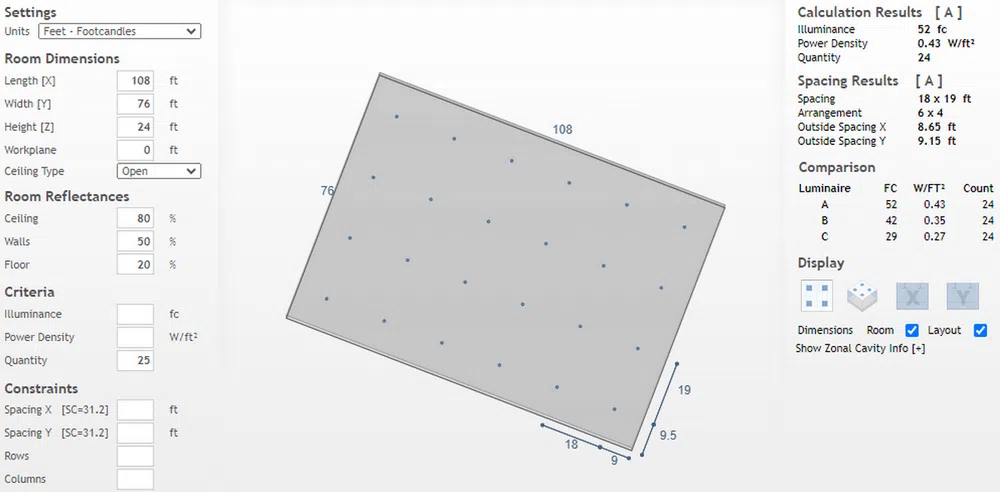

Gymnasium Lighting Installation Plan Metrics

- Mounting height: 24 ft

- Fixture Used: LLS-HB-200A-CC-[C]: 120 / 160 / 200 Watt Adjustable UFO High Bay | 19800 to 33000 Lumens | 4000K / 5000K | 100-277V | White or Black Housing

- FC achieved: 52 FC

- Uniformity (Avg/Min): 2.25

Case Study: Creekside Stables Outdoor Covered Arena using LED Lighting Supply 200 Watt LED UFO High Bay Lights in Franklin, TN

|

After: 200 Watt LED UFO High Bay | 30000 Lumens |

After: 200 Watt LED UFO High Bay | 30000 Lumens |

|

|

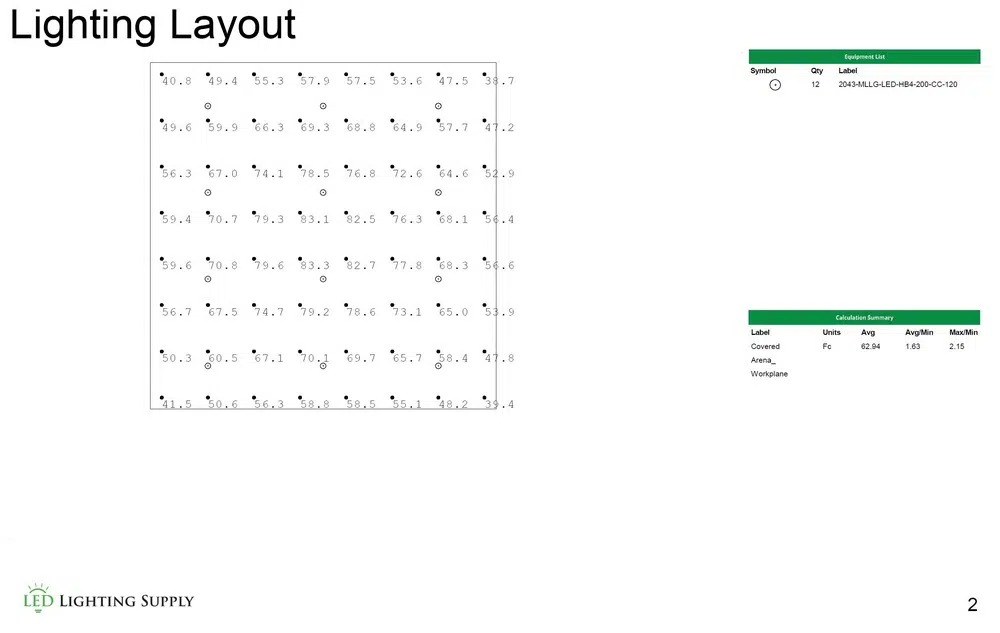

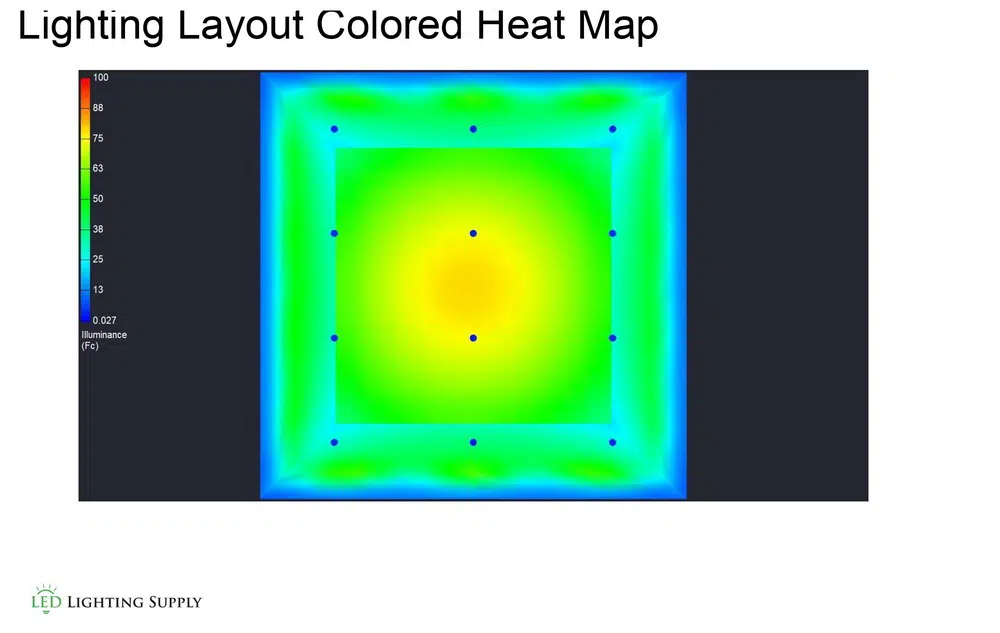

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

Covered Riding Arena Lighting Installation Plan Metrics

- Mounting height: 40 ft

- Fixture Used: (12) MLLG-LED-HB4-200-[Color]-[Beam]: 200 Watt White LED UFO High Bay | 25000 lumens | Replaces 400 Watt Metal Halide

- FC achieved: 62.94 fc average

- Uniformity (Avg/Min): 1.63

Aircraft Hangars see Superior lighting for detailed aircraft maintenance using our powerful LED aircraft hangar lights to achieve brightness requirements for precision work

Professional Support That Delivers Results Before and After Your Purchase

- Photometric planning: We can provide a layout to validate fixture count, spacing, and expected foot-candles for your facility when requested.

- Energy savings calculations: Complimentary ROI-style estimates based on operating hours, utility rates, and current system wattage (inputs and results vary by facility).

- Specification support: Help verifying key datasheet requirements (voltage, environment ratings, temperature range, and applicable listings).

- Warranty & long-term support: US-based support with clear documentation and responsive warranty handling.

Request your free custom lighting plan today and let our Product Specialists help match the right optics, output, and configuration to your application.

Planning & Compliance Notes

- Energy savings vary: Savings depend on operating hours, existing system wattage, controls strategy, and utility rates. On-site results may differ from examples.

- Foot-candle targets are application-specific: Recommended light levels vary by task type, safety requirements, and facility conditions. Verify with a photometric plan.

- Compliance depends on proper specification & installation: Emergency lighting and egress requirements vary by facility and local government authorities. Confirm requirements with your licensed professional and local authority.

- Certifications must match the use case: Always verify UL/ETL/DLC listings and markings on the fixture datasheet for your application (including environment and temperature range)

Common Mistakes and How to Avoid Them

After many years of high bay installations across commercial and industrial facilities, these are the issues that most frequently impact lighting performance, project cost, and long-term reliability.

- Using lumen packages that do not match the mounting height results in insufficient light levels. Use the Ceiling Height Match guidelines in the Quick Selection Guide as a starting point, then verify with photometrics for larger projects, racking, or safety-critical areas.

- Specifying non-DLC-qualified fixtures in projects where rebates are expected. Some utility rebate programs require DLC qualification (often DLC Premium, but requirements vary by program). Always verify the rebate rules and match the fixture's DLC listing to your application.

- Overlooking the need for emergency battery backup units along egress paths. Some facilities require emergency illumination along egress paths for code compliance. Confirm requirements with your licensed professional and local authority.

- Installing motion sensors without adjusting the timeout values to the application. Set occupancy sensor timeouts to match the space. As a starting point, production zones often employ longer delays than storage areas, which are then adjusted during commissioning based on traffic patterns and safety needs.

- Ignoring ambient temperature requirements when selecting fixtures for unconditioned or high-heat spaces. Always check operating temperature ratings, especially for warehouses, foundries, and cold storage facilities.

Commercial and Industrial LED High Bays Frequently Asked Questions

What are LED high bay lights?

LED high bay lights are commercial fixtures designed for large indoor spaces with ceilings 20 feet or higher, delivering high lumen output with engineered optics for warehouses, factories, gyms, aircraft hangars, and distribution centers.

What is the difference between UFO and linear high bay lights?

UFO fixtures provide point-source distribution for open areas and HID replacement, while linear fixtures spread light across a longer source for aisles, racking, and fluorescent replacement with smoother uniformity across rows.

How do I choose the right beam angle for my ceiling height?

Select 120 degrees for under 25 ft, 90 degrees for 25-35 ft, and 60 degrees for 35+ ft mounting heights - verify on datasheet as field-adjustable optics are available on select models.

What foot-candle levels do I need for my application?

Start with 20-30 fc for warehouse storage, 30-50 fc for aisles and distribution, and 50-80 fc for manufacturing - confirm with a photometric plan for your specific facility.

What voltage options are available for LED high bays?

Drivers are available in 120-277V or 277-480V configurations with universal options - verify building electrical service and select a matching driver before ordering.

What energy savings can I expect from LED high bays?

Direct retrofits from HID or fluorescent systems can achieve 50-75% energy reduction, with an additional 30% savings possible through 0-10V dimming with motion sensors in task-based zones.

What is the lifespan of LED high bay lights?

LED high bays deliver 50,000-100,000 hour rated life compared to approximately 15,000 hours for metal halide, reducing maintenance cycles over the service life.

What environmental ratings are available for harsh conditions?

Ratings of IP65-IP69K for dust and water protection and IK08-IK10 for impact resistance are available - verify operating temperature range and specific ratings on the datasheet for your environment.

What certifications should I look for in LED high bays?

Look for UL Listed or ETL Listed for safety compliance and DLC or DLC Premium listings for utility rebate eligibility where available - rebate requirements vary by program and region.

When should I NOT use LED high bay lights?

Do not use high bays when ceiling height is under 20 feet, when you need specialized beam control for sports or outdoor flood applications, when temperature extremes exceed fixture ratings, or when voltage does not match available drivers.

What controls and dimming options are available?

Most models support 0-10V dimming with motion sensor and photocell compatibility - photocell integration can deliver up to 25% additional energy savings depending on facility conditions.

What adjustable features are available on LED high bays?

CCT selectable switches offer 3000K, 4000K, or 5000K options, wattage selectable models allow output adjustment post-install, and optics choices of 60, 90, or 120 degrees are available - features are model dependent.

How do I determine proper fixture spacing?

Plan spacing at roughly 1.2 to 1.5 times mounting height as a starting point, then verify with a photometric layout for larger projects to avoid uneven distribution.

What mounting options are available for high bay lights?

Multiple mounting styles include eye hook, pendant, surface, and chain or cable suspension that work with existing infrastructure for direct replacement capability.

What warranty coverage is provided?

Standard 5-year warranties are backed by US-based support with responsive warranty handling and clear documentation requirements.