Microwave vs PIR Motion Sensors: Which is Better?

Lighting controls extend beyond basic dimmers and timers to include sophisticated sensor technologies that automate lighting operations. Two primary sensor types dominate commercial and residential applications: photo sensors that respond to ambient light levels, and motion sensors that detect occupancy or movement.

Photo sensors automatically control outdoor lighting by detecting ambient light levels, turning fixtures on at dusk and off at dawn. This automation reduces energy consumption and maintenance while ensuring consistent nighttime illumination.

Motion sensors detect movement within a specified detection zone to control LED high bays, low bays, and other fixtures. These electronic devices primarily detect human movement to automate lighting operations and connected building systems.

Modern lighting fixtures can integrate motion sensors directly, improving energy efficiency by 30-50% in typical applications. These sensors reduce energy costs by dimming or switching off lights in unoccupied areas while enhancing security through automatic activation when movement is detected.

Two motion sensor technologies dominate occupancy detection applications: PIR (Passive Infrared) sensors and microwave sensors. Each technology offers distinct advantages for different installation environments and requirements.

How Microwave Motion Sensors Work

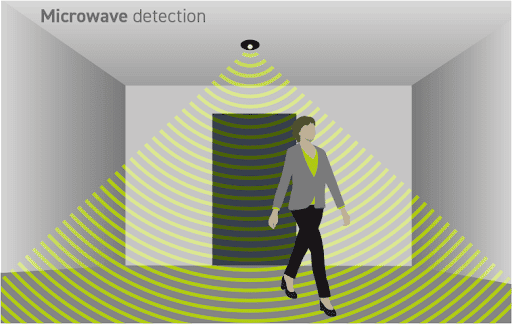

Microwave sensors operate by emitting high-frequency electromagnetic waves (typically 5.8 GHz) and analyzing the reflected signals. The sensor’s transmitter generates continuous microwaves that bounce off stationary objects in the detection zone. The receiver analyzes the echo time-the duration between signal transmission and return-to establish a baseline pattern of the monitored area.

When a person enters the detection zone, their movement creates a Doppler shift in the reflected microwave pattern. This disturbance changes the echo time and frequency characteristics, triggering the sensor to activate connected lighting or security systems. Advanced microwave sensors can determine movement direction and speed by analyzing these frequency shifts.

The sensor processes two distinct wave patterns:

- Normal Wave Pattern: Consistent echo times from stationary objects create a stable baseline. No changes indicate an unoccupied space.

- Altered Wave Pattern: Movement disrupts the baseline pattern, changing echo times and triggering sensor activation. The magnitude of change can indicate object size and movement speed.

Professional-grade microwave sensors can distinguish between approaching and receding movement, filter out small animals, and provide adjustable sensitivity settings for different applications.

How PIR Motion Sensors Work

PIR (Passive Infrared) sensors detect infrared radiation emitted by warm objects, particularly humans and animals. The core component is a pyroelectric sensor that converts thermal radiation into electrical signals.

PIR sensors contain two pyroelectric elements positioned to detect temperature differentials across the monitored area. A specialized Fresnel lens focuses infrared radiation onto these sensors, creating multiple detection zones or “beams” throughout the coverage area.

When a warm object moves across these detection beams, it creates temperature variations that generate electrical signals. The sensor triggers when movement is detected across multiple beams, reducing false activations from air currents or small temperature fluctuations.

PIR sensors operate in cycles to prevent interference from the controlled lighting itself. After activation, the sensor enters a brief reset period before resuming detection, ensuring reliable operation in integrated lighting systems.

Comparative Analysis: Microwave vs PIR Motion Sensors

Microwave Motion Sensor Advantages and Limitations

- Environmental Reliability: Consistent performance across temperature extremes since detection doesn’t rely on thermal signatures

- High Sensitivity: Detects subtle movements with adjustable sensitivity settings, reducing false negatives

- Penetration Capability: Can detect movement through glass, thin walls, and partitions, suitable for complex architectural layouts

- Wide Coverage: Provides 360-degree detection with ranges up to 40 feet diameter

- Limitation – Over-Sensitivity: May trigger from movement outside intended areas, requiring careful positioning and sensitivity adjustment

- Limitation – Higher Cost: More expensive than PIR sensors but offers advanced features and programming options

PIR Motion Sensor Advantages and Limitations

- Energy Efficiency: Passive operation consumes minimal power, ideal for battery-powered applications

- No Electromagnetic Interference: Doesn’t emit signals that could interfere with sensitive electronic equipment

- Cost-Effective: Lower initial cost with reliable performance for standard applications

- Precise Detection: Requires line-of-sight, providing targeted coverage for specific areas

- Limitation – Temperature Sensitivity: Performance varies with ambient temperature; less effective when room temperature approaches body temperature

- Limitation – Directional Coverage: Requires clear line-of-sight; cannot detect through barriers

Application Guidelines for Sensor Selection

Optimal Microwave Sensor Applications

- Warehouses and Industrial Facilities: Wide coverage areas with high ceilings (15-40 feet) and obstacles

- Parking Structures: Multi-level detection through concrete barriers and vehicle coverage

- Security Lighting: Perimeter detection with adjustable range and sensitivity

- Irregularly Shaped Spaces: Areas where line-of-sight limitations make PIR sensors impractical

- Recommended for: Gas stations, loading docks, outdoor areas, conference halls with moveable partitions

Optimal PIR Sensor Applications

- Office Spaces: Individual rooms, cubicles, and defined work areas with clear boundaries

- Corridors and Hallways: Linear spaces with predictable traffic patterns

- Restrooms and Small Rooms: Enclosed spaces where precise activation is required

- Stairwells: Vertical applications with clear detection zones

- Recommended for: Private offices, conference rooms, storage closets, residential applications

Selection Criteria and Installation Considerations

Choose sensors based on ceiling height, coverage area, and environmental factors. Microwave sensors work effectively at 10-40 feet mounting heights, while PIR sensors perform optimally at 8-20 feet. Consider local building codes that may specify sensor requirements for energy compliance.

Professional installation ensures optimal placement, proper electrical connections, and compliance with local codes. Lighting controls integration may require additional programming and commissioning for multi-zone applications.

Safety Notice: Motion sensor installation involves electrical connections that should be performed by qualified electricians in accordance with local electrical codes. Always disconnect power before installation and verify proper operation after completion.

Conclusion

Motion sensors provide significant energy savings and operational benefits for both residential and commercial lighting applications. PIR sensors offer cost-effective solutions for defined spaces, while microwave sensors excel in challenging environments with complex layouts or extreme temperatures.

Proper sensor selection depends on application requirements, environmental conditions, and budget considerations. Professional installation ensures optimal performance and code compliance, making motion-controlled lighting a practical upgrade for new construction and retrofit projects.