Showing 13–24 of 29 results

- SKU:LLS-X-HBLIN8-2-105/90/80-CC | Web ID:2270Availability: 316 In Stock Ships 3-5 Days

- Watts: 80 | 90 | 105

- Lumens: 12000 | 13500 | 15750

- Lumens/Watt: 150

- Replaces: 150 | 250 | 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 113°F

- Rated Life: 100,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Frosted Lens

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 23.2 X 12.6 X 3 in

- Cord Length: No Cord

- Weight: 6.75 lbs

Starting At$143.27 - SKU:LLS-X-HBLIN8-2-165/140/130-CC | Web ID:2271Availability: 2750 In Stock Ships 2-3 Days

- Watts: 130 | 140 | 165

- Lumens: 19500 | 21000 | 24750

- Lumens/Watt: 150

- Replaces: 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 113°F

- Rated Life: 100,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Frosted Lens

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 23.2 X 12.6 X 3 in

- Cord Length: No Cord

- Weight: 6.75 lbs

Starting At$155.19 - SKU:LLS-X-HBLIN8-4-225/195/175-CC | Web ID:2272Availability: 2159 In Stock Ships 3-5 Days

- Watts: 175 | 195 | 225

- Lumens: 26250 | 29250 | 33750

- Lumens/Watt: 150

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 113°F

- Rated Life: 100,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Frosted Lens

- Fixture Color: White

- Dimensions: 44.3 X 12.6 X 3 in

- Cord Length: No Cord

- Weight: 11 lbs

Starting At$202.78 - SKU:LLS-X-HBLIN8-4-300/260/230-CC | Web ID:2273Availability: 2619 In Stock Ships 2-3 Days

- Watts: 230 | 260 | 300

- Lumens: 34500 | 39000 | 45000

- Lumens/Watt: 150

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -40°F to 113°F

- Rated Life: 100,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Frosted Lens

- Fixture Color: White

- Mount: Chain-Cable

- Dimensions: 44.3 X 12.6 x 3 in

- Cord Length: No Cord

- Weight: 11 lbs

Starting At$213.64 - SKU:MLLG-X-LED-HBLIN6-90/105/130-CC | Web ID:2067Availability: 3343 In Stock Ships 3-5 Days

- Watts: 90 | 105 | 130

- Lumens: 13860 | 16170 | 20020

- Lumens/Watt: 150

- Replaces: 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 10kV

- Operating Temp: -40°F to 122°F

- Rated Life: 50,000 hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Polycarbonate Lens

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 14 X 11.5 X 2.1 in

- Cord Length: No Cord

- Weight: 6 lbs

Starting At$114.91 - SKU:MLLG-X-LED-HBLIN6-115/130/155-CC | Web ID:2279Availability: 2111 In Stock Ships 3-5 Days

- Watts: 115 | 130 | 155

- Lumens: 17250 | 19500 | 23250

- Lumens/Watt: 150

- Replaces: 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 10kV

- Operating Temp: -40°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Polycarbonate Lens

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 14 X 11.5 X 2.1 in

- Cord Length: No Cord

- Weight: 7 lbs

Starting At$124.15 - SKU:MLLG-X-LED-HBLIN6-155/180/210-CC-[V] | Web ID:2068100V-277V:1125 In StockShips 3-5 Days277V-480V:691 In StockShips 3-5 Days

- Watts: 155 | 180 | 210

- Lumens: 22880 | 26570 | 31000

- Lumens/Watt: 150

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Polycarbonate Lens

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 14 X 11.5 X 2.1 in

- Cord Length: No Cord

- Weight: 7 lbs

Starting At$139.23 - SKU:MLLG-X-LED-HBLIN6-(240/270/310)-CC-[V] | Web ID:2082100V-277V:287 In StockShips 3-5 Days277V-480V:838 In StockShips 3-5 Days

- Watts: 240 | 270 | 310

- Lumens: 36000 | 40500 | 46500

- Lumens/Watt: 150

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Polycarbonate Lens

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 20.5 X 11.54 X 2.13 in

- Cord Length: No Cord

- Weight: 10 lbs

Starting At$170.00 - SKU:LLS-M-HBLINR-165A-CC | Web ID:2674Back in Stock 3/20

- Watts: 90 | 120 | 165

- Lumens: 13500 | 18000 | 24750

- Lumens/Watt: 150

- Replaces: 250 | 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Surge Protection: 6kV

- Rated Life: 50,000 hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Frosted Polycarbonate Lens

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Surface

- Dimensions: 24.65 x 12.8 x 2

- Cord Length: No Cord

Starting At$155.18 - SKU:LLS-AG-HBLINR-300A-CC | Web ID:2575Availability: 140 In Stock Ships 2-3 Days

- Watts: 180 | 240 | 300

- Lumens: 25200 | 33600 | 42000

- Lumens/Watt: 140

- Replaces: 250 | 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Operating Temp: -22°F to 122°F

- Rated Life: 150,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Frosted Polycarbonate Lens

- Fixture Color: White

- Mount: Chain-Cable

- Dimensions: 35.4 X 11.5 X 2 in

- Cord Length: No Cord

- Weight: 7.3 lbs

Starting At$212.17 - SKU:MLLG-WL-LED-HBLIN6-170-CC-HV | Web ID:2130Availability: 1497 In Stock Ships 3-5 Days

- Watts: 170

- Lumens: 23120

- Lumens/Watt: 136

- Replaces: 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 277V-480V

- Operating Temp: -4°F to 113°F

- Rated Life: 70,000 hours

- Dimmable: 0-10V

- Beam Angle (Std): 110°

- Optics: Polycarbonate Lens | Frosted Lens

- Housing: Galvanized Rolled Iron

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 24.8 X 15.2 X 2.2 in

- Cord Length: No Cord

- Weight: 10 lbs

Starting At$243.40 - SKU:MLLG-WL-LED-HBLIN6-4-300-CC-HV | Web ID:2111Availability: 170 In Stock Ships 3-5 Days

- Watts: 300

- Lumens: 40800

- Lumens/Watt: 136

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 277V-480V

- Operating Temp: -22°F to 113°F

- Rated Life: 200,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 110°

- Optics: Frosted Lens

- Housing: Galvanized Rolled Iron

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 46.5 x 18.9 x 2.2 in

- Cord Length: No Cord

- Weight: 18 lbs

Starting At$433.96

Understanding LED Aircraft Hangar Lighting Solutions

Aircraft hangars have unique lighting needs due to their large spaces and high ceilings. Our Product Specialists know that proper lighting is critical for safety and efficiency. With over 15 years of experience in hangar lighting projects, LED Lighting Supply ensures you get the right solution for your facility.

Our LED high bay lights deliver the concentrated power and lumens needed for large spaces. Facilities using our 60-degree beam angle optics achieve optimal light distribution in high ceiling applications, ensuring illumination reaches both aircraft surfaces and floor work areas.

Use When / Don't Use When

Use LED Aircraft Hangar Lighting When

- High ceiling applications (20-80 ft) need concentrated power and lumens

- Energy cost reduction is priority (60-75% savings vs metal halide/fluorescent)

- Maintenance cost elimination needed to avoid frequent lamp/ballast replacements

- Instant full brightness required for safety and productivity

- Aircraft maintenance operations need 30-200 foot-candles depending on task

Don't Use LED Aircraft Hangar Lighting When

- Ceiling height under 20 ft (risk of over-lighting and glare)

- Hazardous location requirements without confirming Class/Division ratings on datasheets

- Extreme temperature environments without verifying operating temperature range

- Budget constraints prevent proper wattage (undersizing creates safety issues)

- Utility rebate deadlines missed (pre-installation approval required for cost savings)

What We Verify Before You Order

We confirm

- Ceiling height and mounting requirements

- Building voltage compatibility

- Required illumination levels for tasks

- Aircraft clearance and wing span

- Motion sensor placement

If we provide a lighting plan, you will get

- Fixture placement avoiding clearance issues

- Foot-candle calculations for tasks

- Uniformity ratios to prevent dark spots

Note: Guidance is general planning information. Final selection should be validated with a photometric plan and confirmed by a licensed professional when required for code- or safety-critical areas.

Quick Selection Guide

- UFO Round Fixtures (60W-300W): For 20-80 ft ceilings, direct metal halide/HID replacement. Verify wattage on datasheet for ceiling height.

- Linear Rectangular Fixtures (120W-400W): For up to 40 ft ceilings, fluorescent/T5 replacement, wide even distribution.

- 60-90 Degree Beam Angles: Standard for hangars to avoid dark spots. Confirm beam angle needs with a photometric plan.

- Motion Sensors: Place at least 25 ft from hangar doors to prevent nuisance switching. Microwave sensors are best for dusty areas.

- Voltage Compatibility: Confirm building voltage (120V or 277V) before ordering to avoid transformer needs.

- Illumination Levels: Verify required foot-candles for tasks (30-200 FC range). Confirm with photometric analysis.

Tip: Narrow beam angles cause dark spots and poor uniformity. Use 60-90 degree optics unless spot lighting is needed for specific work areas.

Choosing the Right LED Hangar Lighting Solution

With over 15 years of experience, our team has identified optimal fixture types for different hangar applications:

- UFO Round Hangar Lights: Direct replacements for metal halide and HID systems. Waterproof, impact-resistant, for 20-80 ft ceilings. 60W to 300W, multiple beam angles.

- Linear Rectangular Lights: Wide, even distribution for ceilings up to 40 ft. Replaces fluorescent and T5 systems. 120W to 400W.

- Dimmable LED Options: UFO and linear styles with 0-10V or 1-10V dimming. Pair with motion sensors for energy savings.

- Motion Sensor-Equipped Fixtures: Microwave or PIR sensors available. Microwave sensors are best for dusty environments.

- Wattage-Adjustable Solutions: Onboard switches allow wattage and lumen adjustments after installation for flexible light levels.

- Color Temperature Adjustable Lights: Selectable 3000K-5000K. 3000K is warm, 5000K mimics metal halide, 4000K matches fluorescent.

We illuminated this customer's hangar using 100 / 120 / 150 / 200 Watt Adjustable UFO High Bay | 15000 to 30000 Lumens high bay fixtures.

Industry-Standard Illumination Levels for Aviation Facilities

Different hangar activities require specific lighting levels for safety and productivity. Based on industry standards and our project experience, we recommend these illumination targets:

| General Work and Storage | 30 foot candles |

| Aircraft Maintenance with Basic Tasks | 30-50 foot candles |

| Aircraft Maintenance with Detailed Work | 70-100 foot candles |

| Drilling, Riveting, and Fastening Operations | 75 foot candles |

| Final Assembly Work | 100 foot candles |

| Quality Inspection Tasks | 50-200 foot candles |

| Welding Operations | 50 foot candles |

| Aircraft Storage Only | 30-50 foot candles |

The Illuminating Engineering Society (IES) provides guidance on lighting standards for industrial facilities that establish recommended illumination levels for various maintenance and operational tasks in aviation facilities.

Quantified Energy Savings and Maintenance Cost Reductions

Our hangar LED installations deliver 60-75% energy savings compared to metal halide and fluorescent systems, depending on facility conditions. Maintenance cost reductions are also significant, as traditional metal halide fixtures require lamp replacement every 2-3 years and ballast replacement every 5-7 years. Our LED fixtures eliminate these recurring expenses with 50,000+ hour lifespans per manufacturer specifications.

Facilities using our solutions in typical 50,000 square foot hangars save $15,000-25,000 annually in combined energy and maintenance costs. Results vary by facility. Payback period is typically 2-4 years, depending on utility rates and usage.

What are the Cost Savings and ROI When You Convert from Metal Halide to LED?

150W LED UFO High Bay vs 400W Metal Halide Replacement (with ballast)

Assumptions: Based on 16 hours/day, 300 days/year at $0.18/kWh,

30 fixture(s), and a 15% ballast factor applied to the metal halide wattage

(400W lamp + 15% ballast = ~ 460W input).

•

Energy cost and ROI calculations are based on energy savings only and assume an LED fixture cost of

$155.00 per fixture.

• Maintenance savings from reduced bulb and ballast replacements are not included

in these calculations.

| Metal Halide (460W per fixture) |

Annual Energy Cost (per fixture): $397.44 Annual Energy Cost (all 30 fixtures): $11,923.20 5 Year Energy Cost (all fixtures): $59,616.00 5 Year Savings (all fixtures): $0.00 |

| LED UFO High Bay (150W per fixture) |

Annual Energy Cost (per fixture): $129.60 Annual Energy Cost (all 30 fixtures): $3,888.00 5 Year Energy Cost (all fixtures): $19,440.00 5 Year Savings (all fixtures): $40,176.00 |

| Savings & Payback |

Single Fixture Annual Savings (energy only): $267.84 30 Fixture Annual Savings (energy only): $8,035.20 LED Fixture Project Cost (30 fixtures): $4,650.00 Simple Payback from Energy Savings Only: under 7 months |

| Performance Summary |

Energy Reduction: 67% 5-Year ROI (All Fixtures, Energy Only): 764% Lamp Life: 50,000+ (LED) vs 15,000 (MH) |

In this example with 30 fixture(s), total LED fixture investment is approximately $4,650.00, and estimated annual energy-only savings are $8,035.20. Simple payback based on energy savings alone is under 7 months. Maintenance savings from eliminating metal halide bulb and ballast replacements provide additional value throughout the fixture's 50,000-hour lifespan, but are not included in this ROI calculation.

Maintenance Cost Elimination: 400W Metal Halide vs 150W LED Analysis

| Metal Halide Maintenance Requirements |

|

| LED Maintenance Requirements |

|

10-Year Maintenance Cost Analysis Per Fixture:

| Lamp Replacement Costs |

|

| Ballast Replacement Costs |

|

| Labor and Equipment Costs |

|

| Total 10-Year Maintenance Cost |

|

Result: Each 150W LED fixture saves about $650 in maintenance costs over 10 years, excluding energy savings. For 20 fixtures, this is over $13,000 in avoided maintenance expenses.

We used our 240 Watt UFO High Bay | 45600 Lumens fixtures to create even, balanced lighting throughout this hangar

Safety Certifications and Performance Standards

All our hangar fixtures carry essential safety and performance certifications. UL Listed or ETL Listed certification covers electrical safety compliance. DLC Premium qualification ensures performance standards and often enables utility rebates covering 30-50% of project costs.

Our fixtures have IP65 wet location ratings for moisture resistance and IK08 impact resistance, providing durability for demanding hangar environments.

Underwriters Laboratories (UL) maintains lighting testing and certification standards for electrical safety and performance reliability. The Design Lights Consortium (DLC) sets energy efficiency requirements that enable utility rebate programs for qualified LED lighting products.

Comprehensive 5-Year Warranty Protection

All fixtures include our standard 5-year warranty. We process warranty claims directly from our U.S. offices for prompt service. LED Lighting Supply provides responsive support throughout the warranty period.

Proven Benefits of LED Fixtures for Aircraft Hangar Applications

- Extended Service Life: Fixtures provide 50,000+ hours of maintenance-free operation per manufacturer specifications, reducing maintenance costs and disruptions.

- Substantial Energy Cost Reductions: Customers report 60% to 75% energy cost reductions compared to traditional lighting. Occupancy sensors can increase savings.

- Advanced Control Integration: High bay models with motion and occupancy sensors adjust output based on activity.

- Rapid Return on Investment: Energy savings typically yield a 1-2 year payback period, faster with higher utility rates.

- Optimized for High-Ceiling Performance: Designed for 20-80 foot ceilings with multiple optic packages and power levels for effective light distribution.

- Enhanced Safety and Reliability: LED fixtures maintain consistent illumination, unlike metal halide and fluorescent systems that degrade over time.

- Immediate Full Output: Fixtures reach 100% brightness instantly, eliminating warm-up delays.

- Streamlined Installation Process: Suitable for new construction and retrofits. Lower electrical load may eliminate panel upgrades.

The U.S. Department of Energy's research on LED lighting for commercial buildings confirms that LED technology can deliver 60-80% energy savings compared to metal halide and fluorescent systems in large-scale industrial applications like aircraft hangars.

Case Study: Replacement of 1500 Watt Metal Halide Lighting with 480 Watt LED UFO High Bays in Lagos, Nigeria

| After: 480 Watt LED UFO High Bay Light | 76800 Lumens |

|

Lighting Plan We Created for the Customer

|

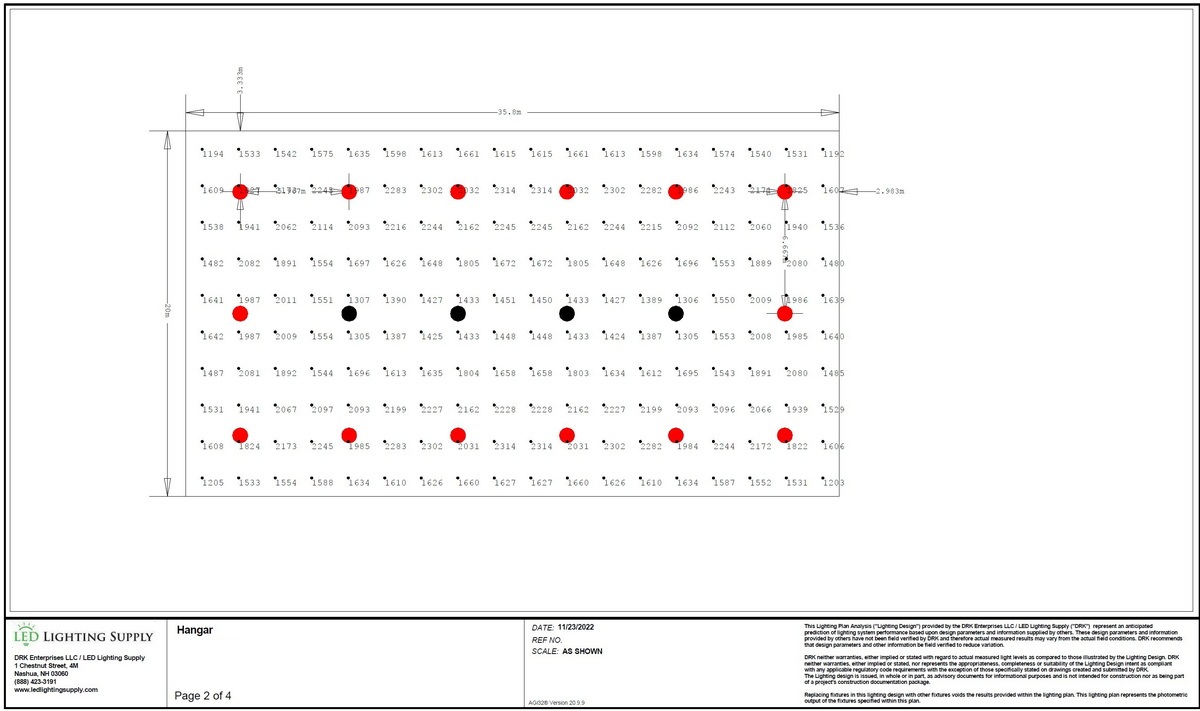

Lighting Plan |

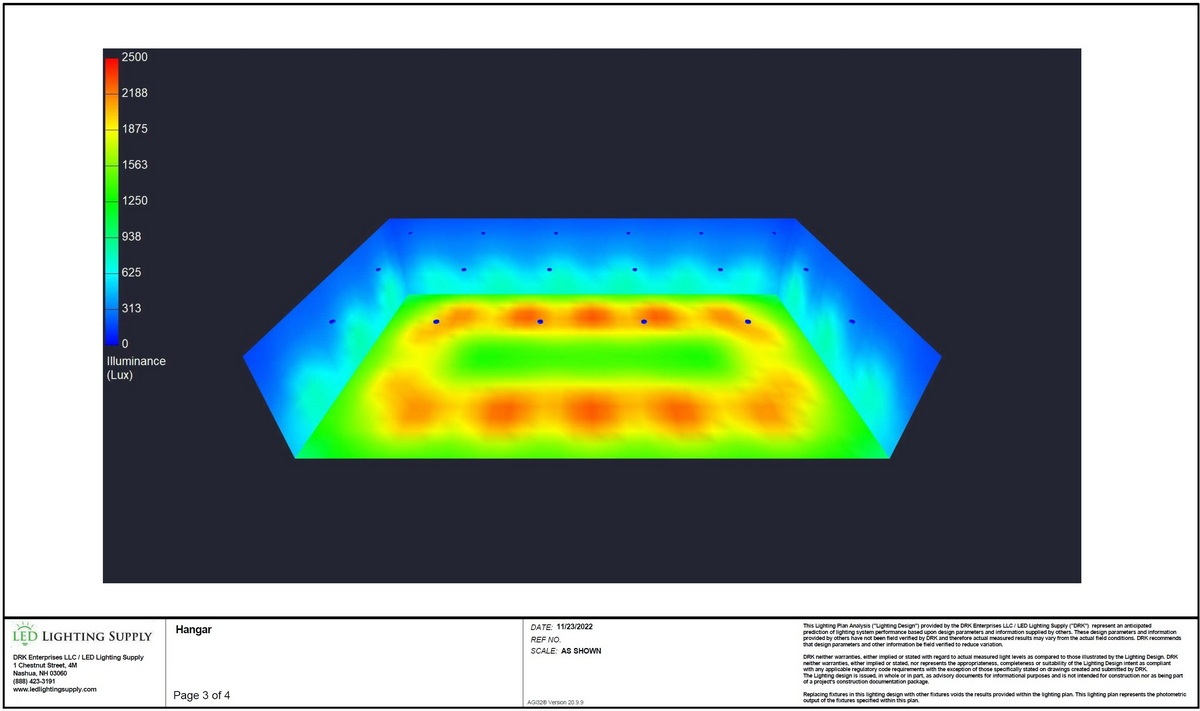

Heat Map |

|

|

Aircraft Hangar Lighting Installation Plan Metrics

- Mounting height: 35 ft ft

- Fixtures Used: MLLG-LED-HB5-480-5-60: 480 Watt LED UFO High Bay | 76800 Lumens | 5000K | 100-277V

- FC achieved: 167 FC average

- Uniformity (Avg/Min): 1.51

Expert Consultation for Optimal Hangar Lighting Solutions

With many fixture options and specifications, selecting the right solution for your hangar can be challenging. Our Product Specialists understand the complexities of aircraft maintenance hangars and bring over 15 years of experience to every project.

We engineer solutions tailored to your needs, facility dimensions, and operational requirements. Our team can provide a complimentary photometric lighting plan for optimal illumination and balanced light distribution. Contact our hangar lighting specialists today to discuss your project and get expert recommendations.

Important: Final fixture selection, wiring, and installation must comply with local electrical codes, aviation safety regulations, and fire protection requirements. All electrical work should be performed by qualified, licensed professionals.

Don't Forget About the Fans

LED Lighting Supply offers both commercial and industrial HVLS fans to improve air circulation and comfort in aircraft hangars. HVLS fans move large volumes of air to regulate temperature, minimize humidity, and reduce stagnant air pockets. Commercial fans are suited for targeted airflow in maintenance or office areas, while HVLS fans provide broad, even air distribution across the hangar floor. Together, they help maintain consistent working conditions, support energy efficiency, and enhance air quality in large aviation environments.

Industrial HVLS Fans and Commercial Fans for Aircraft Hangars

10 Foot HVLS Ceiling Fan | 15000 CFM

12 Foot HVLS Ceiling Fan | 36500 CFM

20 Foot HVLS Ceiling Fan | 137000 CFM

80 Inch Commercial Ceiling Fan | 7 Blades | 11,274 CFM | 120V | Pewter

16 Foot HVLS Ceiling Fan | 92298 CFM

Common Mistakes and How to Avoid Them

Based on our 15+ years of experience, we've identified common costly errors that can impact hangar projects and create unsafe working conditions:

- Narrow beam angles: Cause dark spots and poor uniformity. See beam angle guidance in the Quick Selection Guide above.

- Poor sensor placement: Mounting too close to doors triggers constant cycling. Keep sensors at least 25 feet from hangar doors.

- Undersizing wattage: Leaves mechanics in shadows and fails inspection. Use 200+ watts for over 35 feet and 300+ watts above 50 feet, depending on model.

- Ignoring aircraft clearance: Allow wing span plus 8 feet minimum clearance to avoid equipment damage.

- Voltage mismatches: Specifying 120V fixtures in 277V facilities causes costly modifications. Verify voltage before ordering.

- Skipping photometric analysis: Risks over- or under-lighting. Get calculations done first on large projects.

- Missing utility rebate deadlines: Submit paperwork before installation. Most utilities will not backdate approvals for cost savings.

LED Lighting for Aircraft Hangars Frequently Asked Questions

What are the primary benefits of LED lighting for aircraft hangars?

LED fixtures deliver 60-75% energy savings compared to metal halide and fluorescent systems, provide 50,000+ hours of maintenance-free operation, and reach 100% brightness instantly without warm-up delays.

What ceiling heights are appropriate for LED high bay fixtures in hangars?

UFO round fixtures are designed for 20-80 ft ceilings, while linear rectangular fixtures are suitable for ceiling heights up to 40 ft. Verify wattage requirements on the datasheet for your specific ceiling height.

How do I determine the correct wattage for my hangar application?

UFO fixtures range from 60W to 300W and linear fixtures from 120W to 400W. Ceilings over 35 ft require 200+ watts minimum and above 50 ft require 300+ watts, depending on model specifications.

What beam angles work best for aircraft hangar lighting?

60-90 degree beam angles are standard for hangar applications to avoid dark spots. Narrow beam angles create poor uniformity between fixtures. Verify specific beam angle requirements with a photometric plan.

What illumination levels are required for different hangar tasks?

Requirements range from 30 foot-candles for general work and storage to 50-200 foot-candles for quality inspection tasks. Aircraft maintenance with detailed work requires 70-100 foot-candles.

How should motion sensors be positioned in aircraft hangars?

Position motion sensors minimum 25 ft from hangar doors to prevent nuisance switching. Microwave sensors are recommended for dusty environments due to higher reliability.

What certifications should I look for in hangar LED fixtures?

Look for UL Listed or ETL Listed certification for electrical safety, DLC Premium qualification for utility rebates covering 30-50% of project costs, and IP65 ratings for moisture resistance.

What is the typical payback period for LED hangar lighting upgrades?

Energy savings produce a 1-2 year payback period, with higher utility rates accelerating ROI. Each LED fixture saves approximately $650 in maintenance costs over 10 years compared to 400W metal halide.

What warranty coverage is provided with your hangar lighting fixtures?

All fixtures include a 5-year warranty. Warranty claims are processed directly from United States offices.

When should I NOT use LED aircraft hangar lighting?

Do not use when ceiling height is under 20 ft where high bay fixtures create over-lighting and glare, when hazardous location requirements exist without confirming Class/Division ratings on datasheets, or when extreme temperature environments exist without verifying operating temperature ranges on manufacturer specifications.

What common mistakes should I avoid when selecting hangar lighting?

Avoid narrow beam angles that create dark spots, voltage mismatches between fixtures and building systems, and undersizing wattage that leaves mechanics working in shadows. Confirm building voltage (120V vs 277V) before ordering.

Do you offer photometric planning services for hangar projects?

Yes, complimentary photometric lighting plans are available to ensure optimal illumination levels and balanced light distribution. Plans include precise fixture placement avoiding aircraft clearance issues and foot-candle calculations meeting task-specific requirements.