The Complete Guide to How LED Lights are Made

LED lights are currently among the most energy-efficient lighting systems available. Many traditional lighting types are being replaced by LEDs due to their superior energy efficiency, longer lifespan (typically 25,000-50,000 hours), and improved light quality. LEDs emit light when electrons pass through a semiconductor material, making them fundamentally different from traditional lighting technologies.

LEDs are manufactured into various lighting products including fixtures, bulbs, indicator lights, flashlights, and automotive applications. At LED Lighting Supply, we’ve seen how this technology transforms lighting projects across commercial, industrial, and residential applications.

The Difference Between LED Lights and Traditional Lights

Traditional incandescent lighting creates light by heating a wire filament until it glows. Fluorescent lights use electrical discharge through gas to produce light. Both methods generate significant heat as a byproduct.

LEDs create light through electronic excitation rather than heat generation. This fundamental difference allows LEDs to convert more electrical energy into visible light while producing minimal heat, resulting in greater energy efficiency and longer operational life.

LED Light Construction

LED lights consist of a small chip with layers of semiconductor material. LED packages contain one or more chips mounted on heat-conducting material known as a heat sink, covered by a lens or optic.

The LEDs are placed on a circuit board that can incorporate lighting controls such as:

- Light sensing capabilities

- Dimming functionality

- Preset timing controls

- Programmable voltage regulation

The circuit board is positioned on an additional heat sink to regulate LED temperature. Everything is then sealed inside a lighting fixture, architectural structure, or bulb housing.

How an LED Light Works

LEDs use semiconductor diodes made from crystalline material that requires added impurities (dopants) to conduct electricity effectively. These impurities are precisely introduced during manufacturing to create specific electrical properties.

One semiconductor layer has a surplus of electrons (N-type), while the other layer has fewer electrons (P-type). When voltage is applied, electrons move from the N-type layer to the P-type layer through the P-N junction. This electron movement releases energy in the form of visible light through a process called electroluminescence.

How are LED Lights Made? – The Production Process of LED Lights

Understanding LED manufacturing helps explain why quality varies between products and why professional-grade LEDs offer superior performance and reliability.

Design Stage

Before manufacturing begins, engineers determine these critical LED characteristics:

- Target lighting application and environment

- Color temperature requirements (measured in Kelvin)

- Brightness levels (measured in lumens)

- Energy efficiency targets

- Metal contact patterns for optimal electrical connection

These specifications are influenced by diode layer thickness, semiconductor materials used, and the types of dopant impurities required. This design phase ensures the final LED product meets specific performance requirements.

Step 1: Production of Semiconductor Wafers

Semiconductor wafer production creates the foundation material for LED chips:

- Element mixing: In a high-temperature, high-pressure chamber, purified elements including gallium, arsenic, and phosphorus are mixed and heated until they form a liquid solution.

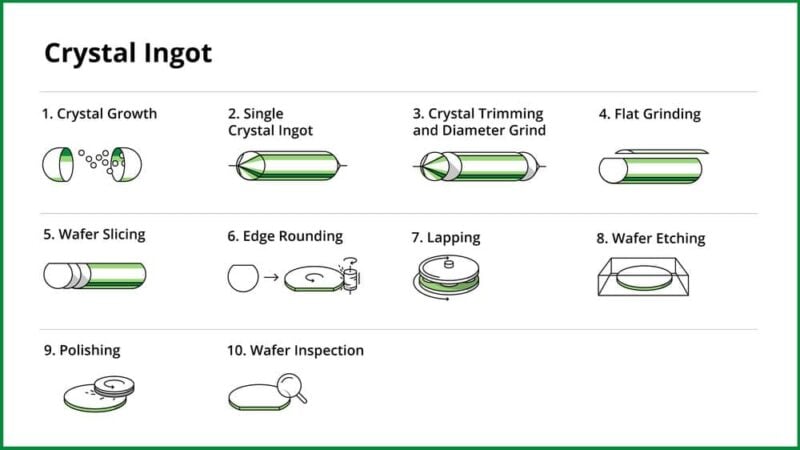

- Crystal formation: A specialized rod extracts material from the mixture and is slowly withdrawn. The solution cools and crystallizes at the rod’s end, forming a cylindrical crystal ingot.

- Wafer slicing: The crystal ingot is precision-sliced into thin wafers and polished until the surface is extremely smooth for optimal layer adhesion.

- Cleaning: Wafers are cleaned in specialized solvents to remove any contamination that could affect performance.

Step 2: Doping – Add Layers of Semiconductor Material to the Wafer

Additional semiconductor crystal layers are grown on the base wafer. During this stage, specific impurities or dopants (typically nitrogen and zinc) are precisely added to create electrical properties.

This process creates two distinct regions:

- P-type layer: Doped with acceptor impurities that create electron-deficient areas (positive charge carriers)

- N-type layer: Doped with donor impurities that create electron-rich areas (negative charge carriers)

When voltage is applied, electrons migrate from the N-type to P-type layer through the P-N junction, generating light energy through this controlled electron movement.

Step 3: Define the Metal Contact Patterns on the Semiconductor

Metal contact patterns are applied based on whether the diode will operate individually or as part of an array. The contact metal is deposited using vapor deposition in a high-temperature, vacuum-sealed chamber.

The metal is heated until it vaporizes, then condenses uniformly onto the wafer surface, creating precise electrical connection points essential for reliable LED operation.

Step 4: Mount the Diode(s) onto the Package

Individual diodes are mounted onto their final package assemblies. Fine wire leads connect each diode to the contact metals using specialized bonding techniques. The complete assembly receives a protective coating or encapsulation to ensure long-term reliability.

Why LED Manufacturing Quality Matters

Advanced processing techniques now enable semiconductor wafer production with unprecedented uniformity and purity. These manufacturing improvements directly impact LED efficiency, brightness consistency, and operational lifespan.

Higher-quality manufacturing processes also allow multiple LED devices to be integrated onto single chips, enabling more sophisticated lighting solutions with better performance characteristics.

When selecting LEDs for professional applications, understanding these manufacturing fundamentals helps ensure you choose products that will deliver reliable, long-term performance for your specific lighting requirements.