Showing 13–24 of 32 results

- SKU:MLLG-E-LED-EXPLD-100-50-[V]-C1D1 | Web ID:1281100V-277V:174 In StockShips 3-5 Days277V-480V:Built to Order 6 Weeks

- Watts: 100

- Lumens: 14000

- Lumens/Watt: 140

- Replaces: 200 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke

- Dimensions: 15.7 X 11.2 X 9.96 in

- Weight: 26.9 lbs

Starting At$1,027.27 - SKU:MLLG-E-LED-EXPLD-150-50-[V]-C1D1 | Web ID:1282100V-277V:116 In StockShips 3-5 Days277V-480V:51 In StockShips 3-5 Days

- Watts: 150

- Lumens: 21000

- Lumens/Watt: 140

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke

- Dimensions: 15.7 X 11.2 X 9.96 in

- Weight: 26.9 lbs

Starting At$1,072.73 - SKU:MLLG-E-LED-EXPLI2-50-50-U-C1D1 | Web ID:1928Availability: 111 In Stock Ships 3-5 Days

- Watts: 50

- Lumens: 7000

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 24 x 5.5 x 8.1

- Weight: 20 lbs

Starting At$854.55 - SKU:MLLG-E-LED-EXPLI-40-50-[V]-C1D1 | Web ID:1288100V-277V:94 In StockShips 3-5 Days277V-480V:Built to Order 6 Weeks

- Watts: 40

- Lumens: 5600

- Lumens/Watt: 140

- Replaces: 175 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 47 X 5.5 X 8.1 in

- Weight: 26 lbs

Starting At$1,072.73 - SKU:MLLG-E-LED-EXPLI-60-50-[V]-C1D1 | Web ID:1603100V-277V:Out of Stock277V-480V:Built to Order 6 Weeks

- Watts: 60

- Lumens: 8400

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 47 in X 5.5 in X 8.1 in

- Weight: 26 lbs

Starting At$1,133.93 - SKU:MLLG-E-LED-EXPLI-80-50-[V]-C1D1 | Web ID:1289100V-277V:108 In StockShips 3-5 Days277V-480V:Built to Order 6 Weeks

- Watts: 80

- Lumens: 11200

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 47 X 5.5 X 8.1 in

- Weight: 26 lbs

Starting At$1,180.18 - SKU:MLLG-E-LED-EXPLI-100-50-[V]-C1D1 | Web ID:1927100V-277V:106 In StockShips 3-5 Days277V-480V:Built to Order 6 Weeks

- Watts: 100

- Lumens: 14000

- Lumens/Watt: 140

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 47 X 5.5 X 8.1 in

- Weight: 26 lbs

Starting At$1,236.36 - SKU:MLLG-E-LED-EXPLG-20-50-C1D1 | Web ID:2081Back in Stock 3/5

- Watts: 20

- Lumens: 2800

- Lumens/Watt: 140

- Replaces: 100 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 360°

- Optics: Spherical Tempered Glass Dome

- Mount: Surface | 3/4 in NPT Pendant

- Dimensions: 12.5 X 8.8 in

- Weight: 14 lbs

Starting At$461.54 - SKU:MLLG-E-LED-EXPLG-30-50-C1D1 | Web ID:1286Availability: 180 In Stock Ships 3-5 Days

- Watts: 30

- Lumens: 3900

- Lumens/Watt: 130

- Replaces: 100 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V

- Operating Temp: -22°F to 122°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 360°

- Optics: Spherical Tempered Glass Dome

- Mount: 3/4 in NPT Pendant

- Dimensions: 12.5 X 8.8 in

- Weight: 14 lbs

Starting At$481.82 - SKU:MLLG-E-LED-EXPLG-40-50-C1D1 | Web ID:1611Availability: 158 In Stock Ships 2-3 Days

- Watts: 40

- Lumens: 5200

- Lumens/Watt: 130

- Replaces: 150 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V

- Operating Temp: -40°F to 149°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 360°

- Optics: Spherical Tempered Glass Dome

- Mount: 3/4 in NPT Pendant

- Dimensions: 6.8 X 16.1 in

- Weight: 14 lbs

Starting At$518.18 - SKU:MLLG-E-LED-EXPLS-10-50-C1D1 | Web ID:1897Availability: 67 In Stock Ships 2-3 Days

- Watts: 10

- Lumens: 1300

- Lumens/Watt: 130

- Color Temp: 5000K

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V

- Surge Protection: 10kV

- Operating Temp: -40°F to 140°F

- Rated Life: 50,000 (L70) hours

- Dimmable: No

- Mount: Wall

- Dimensions: 15.6 x 14.7

- Weight: 17.6 lbs

Starting At$1,224.00 - SKU:MLLG-E-LED-EXPLJ-3-50-C1D1 | Web ID:1766Built to Order 6 Weeks

- Watts: 3

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V

- Operating Temp: -40°F to 140°F

- Rated Life: 50,000 (L70) hours

- Dimmable: No

- Optics: Tempered Glass Lens

- Mount: Chain-Cable | 3/4 in NPT Pendant

- Dimensions: 16 X 11.7

- Weight: 14 lbs

Starting At$1,856.04

Class 1 Div 1 LED Lighting Solutions for Class 1 Division 1 Hazardous Environments

Class 1 Division 1, or C1D1, is the most critical explosion-proof classification defined by the National Electrical Code for hazardous locations. These areas contain explosive atmospheres where concentrations of flammable vapors, gases, or liquids may be present continuously or during normal operating conditions. With over 15 years of experience in hazardous location lighting, LED Lighting Supply's expertise ensures proper fixture selection for these demanding environments. Our Product Specialists understand how standard lighting can become an ignition source, making specialized explosion proof fixtures mandatory for worker safety and regulatory compliance.

According to OSHA's hazardous locations standards, electrical equipment in Class 1 Division 1 areas must be specifically approved and marked for use in explosive atmospheres. The agency emphasizes that improper electrical equipment can serve as ignition sources, making compliance with National Electrical Code requirements essential for worker protection in facilities handling flammable substances.

Understanding Class 1 Division 1 Hazardous Area Classifications

The National Electrical Code (NEC), published by the National Fire Protection Association (NFPA 70), classifies Class I hazardous locations based on the presence of flammable gases or vapors under normal operating conditions. Within Class I, hazardous atmospheres are divided into Groups A through D, based on ignition energy, explosion pressure, and gas characteristics:

- Group A - Acetylene

- Group B - Hydrogen or gases of equivalent hazard

- Group C - Ethylene or gases of equivalent hazard

- Group D - Propane, butane, methane, benzene, and similar hydrocarbons

Groups A and B represent the highest explosion risk due to low ignition energy thresholds and aggressive combustion. Equipment approved for these environments is subject to more stringent design, testing, and certification requirements.

LED Lighting Supply specifies and supplies Class I, Division 1 LED luminaires in strict accordance with NEC gas group classification requirements. Most Class I Div 1 fixtures offered are certified for Groups C and D, with select models approved for Group B applications where required.

All Class I, Division 1 luminaires supplied by LED Lighting Supply are certified by nationally recognized testing laboratories (NRTLs) in accordance with applicable NEC, UL, and CSA standards. Gas group compatibility must be verified during the lighting design and submittal process, as incorrect group selection can result in failed inspections, insurance conflicts, and serious safety violations.

Critical Safety and Compliance Notice: Class I, Division 1 hazardous locations involve the presence of flammable gases or vapors under normal operating conditions and require equipment specifically certified for continuous or frequent exposure to explosive atmospheres.

Information provided regarding Class I, Division 1 LED lighting is intended for general technical guidance only and does not replace applicable codes, standards, or site-specific engineering evaluation. Final equipment selection, installation, and approval must be performed by qualified professionals and accepted by the authority having jurisdiction (AHJ) in accordance with NFPA 70 (National Electrical Code), OSHA regulations, and all applicable local requirements.

Case Study: Conversion of existing paint booth metal halide explosion proof lighting to LED Lighting Supply Class 1 Division 1 Fixtures in Chicago, IL

|

Before: 100 Watt Round Explosion Proof Metal Halide Light |

After: 50 Watt Round Explosion Proof LED Light | 7000 Lumens |

|

|

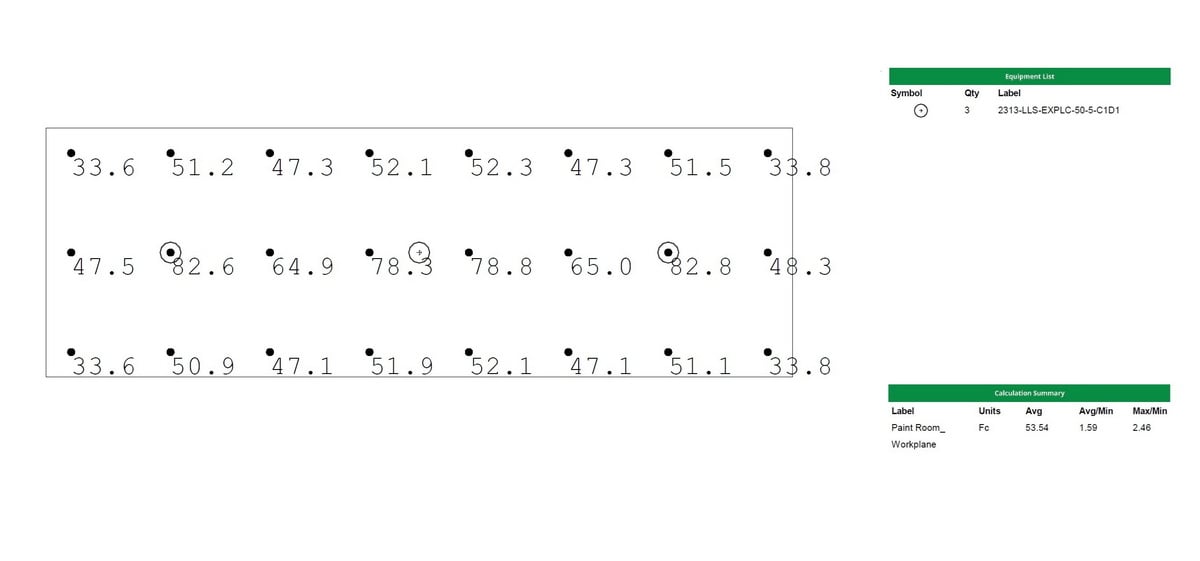

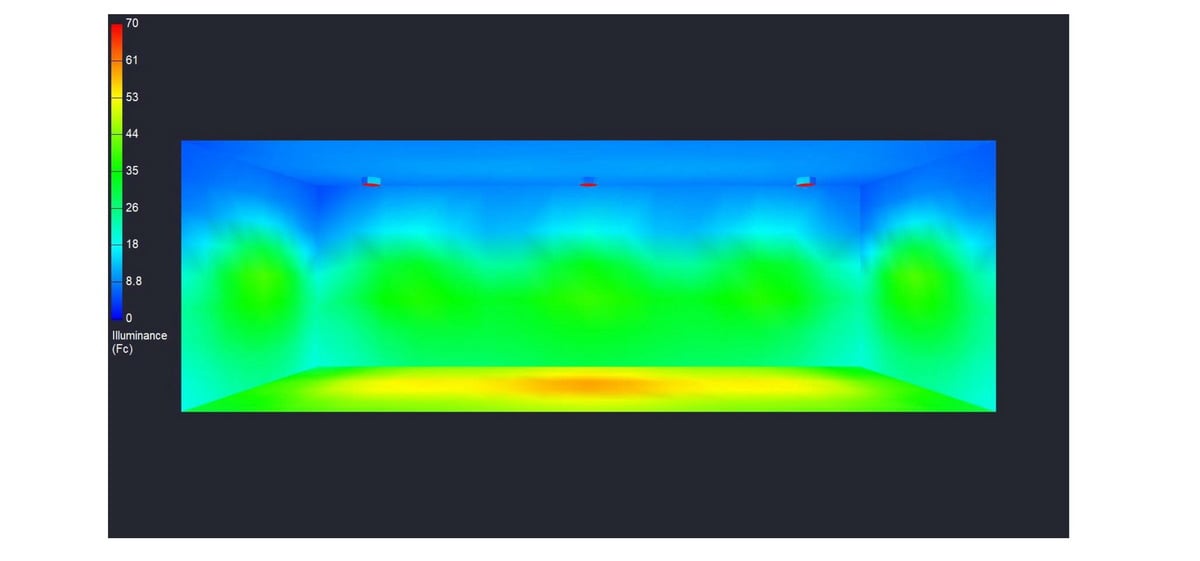

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

Explosion Proof Lighting Installation Plan Metrics

- Mounting height: 10 ft

- Fixture Used: LLS-EXPLC-50-5-C1D1: 50 Watt Round Explosion Proof LED Light | 7000 Lumens | Class 1 Div 1 | 5000K | 100-277V

- FC achieved: 53.54 FC average

- Uniformity (Avg/Min): 1.59

Use When / Don't Use When

Use Class 1 Division 1 LED Fixtures When

- Continuous hazardous atmosphere exposure - flammable vapors, gases, or liquids present during normal operations

- Critical industrial applications - petroleum refineries, chemical processing, oil platforms, drilling rigs, distilleries

- Gas groups A through D are documented - facility hazmat documentation identifies specific combustible substances

- Worker safety is paramount - preventing ignition sources in explosive atmospheres is mandatory for compliance

- Authority having jurisdiction requires - local codes and OSHA standards mandate explosion proof electrical equipment

Don't Use Class 1 Division 1 LED Fixtures When

- Only occasional hazardous conditions exist - Class 1 Division 2 fixtures may be appropriate for abnormal conditions only

- Non-hazardous industrial areas - standard LED high bays or industrial fixtures provide better value

- Budget constraints override safety requirements - never compromise on properly certified fixtures in hazardous locations

- Gas group classification is unknown - fixture selection requires confirmed compatibility with specific combustible substances

- Installation team lacks hazardous location experience - improper installation voids certifications and creates safety violations

What We Verify Before You Order

We confirm

- Division 1 vs Division 2 requirements based on normal operating conditions

- Environmental protection needs (IP ratings, corrosion resistance, marine grade)

- Mounting requirements (pendant, yoke, wall mount) and structural considerations

- Electrical specifications (voltage, conduit requirements, sealing needs)

If we provide a lighting plan, you will get

- Fixture placement optimized for hazardous area boundaries and safety compliance

- Detailed ROI analysis comparing current explosion proof fixtures to LED solutions

- Foot candles and light uniformity in the area or space

Note: Guidance is general planning information. Final selection should be validated with a photometric plan and confirmed by a licensed professional when required for code- or safety-critical areas.

Critical Industrial Applications Requiring Class 1 Division 1 Lighting

- Oil and Gas Industry - petroleum refineries, drilling rigs, oil and gas operations, petrochemical facilities

- Chemical Manufacturing and chemical processing facilities

- Ocean, Marine, and Aerospace Industries

- Food and Alcohol Production facilities, Distilleries

- Electrical Power Generation Industry (Natural Gas)

- Waste Treatment Facilities and Plants

- Metal Treatment and Processing operations

- Dry Cleaning Plants

Quick Selection Guide

- Use only when flammable gases or vapors may be present continuously or during normal operating conditions

- Confirm gas group classification (A, B, C, or D) from facility hazmat documentation and verify fixture certification matches

- Verify nameplate marking shows "Class I Div 1" certification - Division 2 fixtures are not acceptable for Division 1 areas

- Ensure all electrical components (junction boxes, conduit fittings, disconnects) carry the same C1D1 rating as fixtures

- Calculate voltage drop for long conduit runs, as explosion proof fixtures are less tolerant of low-voltage conditions

- Confirm IP rating meets actual environmental conditions beyond explosion proof requirements (washdown, corrosive, marine)

Tip: Never retrofit LED boards into old explosion proof housings - this voids all certifications and creates serious liability during insurance inspections.

Optimized Solutions for Specific Applications

| Petrochemical Refineries | Require pendant or yoke-mounted explosion-proof fixtures supporting 120-277V input. Continuous vapor presence demands the highest hazardous-location certifications for safe, compliant operation. |

| Oil Platforms | Need marine-grade housings with IP66 saltwater protection. Instant-on LED startup eliminates dangerous delays during shift changes or emergency evacuations. |

| Chemical Processing Plants | Operate with combustible ethylene vapors and require Group C-certified fixtures. Wall-mount options improve access in areas where overhead fixtures conflict with process equipment. |

| Natural Gas Facilities | Require Group D certified lighting with vibration-resistant mounting. Sealed optical chambers prevent methane infiltration while maintaining stable illumination. |

| Distillery Operations | Need a combination of NSF food-grade compliance and explosion-proof performance. Stainless steel housings resist harsh sanitizing chemicals and prevent alcohol vapor ignition. |

| Waste Treatment Plants | Demand corrosion-resistant finishes and IP65 wet-location protection. Pendant-mounted fixtures effectively illuminate tanks, walkways, and elevated structures. |

| Drilling Rigs | Require portable explosion-proof lighting with temporary mounting options. Battery-backup systems provide safe illumination during power failures in critical operations. |

| Marine Engine Rooms | Benefit from compact fixtures with vibration-resistant drivers and shock-mounted hardware. Low heat output reduces compartment temperatures while providing reliable task lighting. |

Comprehensive Safety and Performance Certifications

All our fixtures carry essential certifications, including DLC Premium for energy efficiency and rebate eligibility, UL Listed and ETL Listed for electrical safety and compliance, and NSF for sanitation and cleanability in applicable models. LED Lighting Supply's expertise ensures these certifications provide safety, performance, and energy efficiency while qualifying your project for utility rebates and tax incentives. Our DLC Premium certification guarantees the highest efficiency standards and maximum rebate eligibility for cost-effective operations.

Comprehensive 5-Year Warranty and USA-Based Support

All our Class 1 Division 1 fixtures include a comprehensive 5-Year warranty, model dependent, with all warranty support provided by our USA-based team. Our Product Specialists understand the critical importance of keeping your hazardous location lighting operational and will work quickly to resolve any warranty issues.

With over 15 years of experience, we take customer support seriously and ensure compliance and safety throughout your fixture's operational life. Contact our specialists today to discuss your Class 1 Division 1 lighting requirements and receive a customized solution for your facility.

Proven Benefits of LED Lighting Supply's Class 1 Div 1 Solutions

- Certified Hazardous Location Safety - Each fixture undergoes extensive testing and qualification for Class I, Division 1 environments, ensuring they never become ignition sources even during electrical faults or abnormal operating conditions.

- Extended Operational Life - Engineered for 50,000+ hour lifespans, these fixtures eliminate routine bulb and ballast changes, reducing downtime and minimizing safety risks in hazardous areas.

- Dramatic Energy Reduction - Customers frequently report 65% lower energy consumption compared to metal halide or fluorescent explosion-proof lighting, resulting in immediate operational cost reductions.

- Superior Energy Conversion - LEDs convert electricity into light with minimal heat generation, reducing HVAC load while maintaining consistent illumination throughout the fixture's lifespan.

- Enhanced Area Security - Flicker-free LED illumination eliminates dimming and output degradation common with metal halide systems, ensuring consistent visibility in safety-critical environments.

- Harsh Environment Durability - Constructed with galvanized and powder-coated housings, these fixtures withstand extreme temperatures, moisture, vibration, and corrosive atmospheres while maintaining explosion-proof integrity.

- Immediate Full Output - LED fixtures reach 100% brightness instantly, eliminating the warm-up periods required by HID systems - a critical advantage during emergencies.

- Streamlined Installation - Designed for compatibility with standard explosion-proof mounting and wiring methods, our fixtures provide straightforward retrofit installation while maintaining all hazardous-location compliance requirements.

The U.S. Department of Energy's LED lighting research demonstrates that LED technology can reduce energy consumption by 75% or more compared to traditional lighting sources. This efficiency advantage is especially valuable in industrial facilities where lighting operates continuously, as the combination of lower energy costs and reduced maintenance delivers substantial operational savings over the fixture lifespan.

Expert Technical Support and Custom Lighting Design Services

LED Lighting Supply provides complimentary custom lighting plans specifically designed for your Class 1 Division 1 facility layout. Our Product Specialists analyze your hazardous areas to determine exact fixture placement, optimal wattage requirements, and precise group compatibility for maximum safety compliance.

We calculate projected energy savings by comparing your current explosion-proof fixtures to our LED solutions, providing a detailed ROI analysis that includes maintenance cost reductions from our 50,000+ hour lifespan advantage. Our technical team has engineered solutions for over 10,000 hazardous location projects, giving us unique insight into optimizing illumination levels while minimizing fixture quantities for cost-effective installations.

Common Installation and Specification Mistakes

- Using Division 2-rated fixtures in Division 1 areas because they look identical - verify nameplate marking shows "Cl I Div 1" certification

- Installing Group D fixtures where Group B or C gases are present - check facility hazmat documentation for specific gas groups

- Mixing standard electrical components with explosion proof fixtures - all components need matching C1D1 ratings

- Attempting to retrofit LED boards into old explosion proof housings - this voids all certifications

- Overlooking conduit sealing requirements between hazardous and non-hazardous areas per NEC 501.15

- Specifying insufficient IP ratings for washdown areas or corrosive environments beyond explosion proof requirements

- Forgetting to calculate voltage drop in long conduit runs - explosion proof fixtures are less tolerant of low-voltage conditions

LED Lights for Class 1 Division 1 Hazardous Locations Frequently Asked Questions

What makes a light fixture Class 1 Division 1 rated?

Class 1 Division 1 fixtures are certified for areas where flammable vapors, gases, or liquids may be present continuously or during normal operating conditions. Verify the nameplate marking shows Class I Div 1 certification - Division 2 fixtures are not acceptable for Division 1 areas.

What industries require Class 1 Division 1 LED lighting?

Applications include petroleum refineries, chemical processing, oil platforms, drilling rigs, and distilleries where flammable vapors or gases are present during normal operations. Other documented applications include marine and aerospace industries, natural gas power generation, waste treatment facilities, and dry cleaning plants.

What are the gas group classifications for Class 1 Division 1?

Class I hazardous atmospheres are divided into Groups A through D: Group A (acetylene), Group B (hydrogen), Group C (ethylene), and Group D (propane, butane, methane, benzene). Confirm gas group classification from facility hazmat documentation and verify fixture certification matches.

What certifications should Class 1 Division 1 LED fixtures have?

Fixtures carry UL Listed, ETL Listed, and DLC Premium certifications. All Class I Division 1 luminaires are certified by nationally recognized testing laboratories in accordance with applicable NEC, UL, and CSA standards.

How do LED Class 1 Division 1 fixtures compare to metal halide?

Customers report 65% lower energy consumption compared to metal halide or fluorescent explosion-proof lighting. LED fixtures reach 100% brightness instantly, eliminating warm-up periods required by HID systems.

What is the lifespan of Class 1 Division 1 LED fixtures?

Fixtures are engineered for 50,000+ hour lifespans, eliminating routine bulb and ballast changes and reducing downtime in hazardous areas.

What warranty comes with Class 1 Division 1 LED fixtures?

All fixtures include a 5-year warranty, model dependent, with warranty support provided by a USA-based team.

What IP ratings are available for Class 1 Division 1 fixtures?

Available ratings include IP65 wet-location protection and IP66 saltwater protection for marine-grade applications. Confirm IP rating meets actual environmental conditions beyond explosion proof requirements, including washdown, corrosive, or marine environments.

What mounting options exist for Class 1 Division 1 LED fixtures?

Mounting options include pendant, yoke, and wall mount configurations. Structural considerations and conduit requirements should be confirmed during specification.

What voltage options are available for Class 1 Division 1 fixtures?

Fixtures support 120-277V input. Calculate voltage drop for long conduit runs, as explosion proof fixtures are less tolerant of low-voltage conditions.

Can existing explosion proof fixtures be retrofitted with LED?

Never retrofit LED boards into old explosion proof housings - this voids all certifications and creates serious liability during insurance inspections.

What common mistakes occur when specifying Class 1 Division 1 lighting?

Mistakes include using Division 2-rated fixtures in Division 1 areas, installing Group D fixtures where Group B or C gases are present, and mixing standard electrical components with explosion proof fixtures. All electrical components must carry the same C1D1 rating as fixtures.

When should Class 1 Division 1 fixtures NOT be used?

Do not use when only occasional hazardous conditions exist (Class 1 Division 2 fixtures may be appropriate), in non-hazardous industrial areas, or when gas group classification is unknown. Fixture selection requires confirmed compatibility with specific combustible substances.

What support services are available for Class 1 Division 1 projects?

Services include confirmation of Division 1 vs Division 2 requirements, environmental protection needs, mounting requirements, and electrical specifications. Lighting plans provide fixture placement optimized for hazardous area boundaries, detailed ROI analysis, and foot candle calculations. Final selection should be validated with a photometric plan and confirmed by a licensed professional when required.