Showing 13–16 of 16 results

- SKU:MLLG-WL-LED-HBLIN6-4-400-CC | Web ID:2123Availability: 1145 In Stock Ships 2-3 Days

- Watts: 270 | 340 | 400

- Lumens: 41600 | 50000 | 56100

- Lumens/Watt: 150

- Replaces: 1000 | 1500 | 2000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Operating Temp: -4°F to 122°F

- Rated Life: 70,000 hours

- Dimmable: 0-10V

- Beam Angle (Std): 90°

- Optics: Polycarbonate Lens

- Housing: Galvanized Rolled Iron

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Pendant | Surface

- Dimensions: 44.2 X 10.2 X 1.8 in

- Cord Length: No Cord

- Weight: 10 lbs

Starting At$292.45 - SKU:MLLG-AL-LED-HBLIN5-500-CC | Web ID:1706Availability: 711 In Stock Ships 2-3 Days

- Watts: 320 | 400 | 500

- Lumens: 48960 | 61200 | 76900

- Lumens/Watt: 150

- Replaces: 1500 Watt Metal Halide

- Color Temp: 3500K | 4000K | 5000K

- CRI: 80+

- Voltage: 100V-277V

- Operating Temp: -22°F to 122°F

- Rated Life: 100,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Surface

- Dimensions: 39.5 X 12 X 2 in

- Cord Length: No Cord

- Weight: 14.6 lbs

Starting At$346.15 - SKU:LLS-AG-HBSPU-300A-5 | Web ID:2713Built to Order 8 Weeks

- Watts: 125 | 225 | 300

- Lumens: 19,375 | 34,875 | 46,500

- Lumens/Watt: 155

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IK Rating: IK08

- Voltage: 100V-277V | 277V-480V Optional

- Surge Protection: 6kV

- Operating Temp: -22°F to 122°F

- Rated Life: 200,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 45°

- Optics: Frosted Tempered Glass

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Yoke

- Dimensions: 19.25 x 15.75 x 5

- Weight: 11

Starting At$646.37 - SKU:LLS-AG-HBSPU-600A-5 | Web ID:2712Built to Order 8 Weeks

- Watts: 300 | 450 | 600

- Lumens: 46,500 | 69,750 | 93,000

- Lumens/Watt: 155

- Replaces: 1000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IK Rating: IK08

- Voltage: 100V-277V | 277V-480V Optional

- Surge Protection: 6kV

- Operating Temp: -22°F to 122°F

- Rated Life: 200,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 45°

- Optics: Frosted Tempered Glass

- Fixture Color: White

- Mount: Chain-Cable

- Mount (Opt): Yoke

- Dimensions: 19.25 x 23.6 x 6.2 in

- Weight: 17.5

Starting At$931.29

Quick Selection Guide

- Commonly used when replacing 4-8 tube F54/T5/HO fluorescent fixtures in manufacturing, warehouses, gyms, and retail spaces with 15-30 foot ceilings

- Typical replacement guidance: 4-tube systems need 12,000-18,000 LED lumens, 6-tube systems need 18,000-24,000 lumens, 8-tube systems need 24,000-40,000 lumens (verify with photometric plan)

- Choose 277-480V high voltage models for industrial electrical systems; standard 100-277V works for most commercial applications

- Motion sensor models require dimming wire connections for proper sensor operation - not just standard on/off wiring

- Do not use above 30 feet mounting height where wide distribution becomes ineffective - UFO high bays work better for those applications

- Dry location only - these lack IP ratings needed for food processing washdown or wet environments

Tip: Do not size based on fluorescent tube count alone. A 6-tube fluorescent in a 15-foot space needs different LED lumens than the same fixture in a 25-foot application.

Use When / Do not Use When

Use LED Linear High Bays When

- Replacing F54/T5/HO fluorescent systems in warehouses, manufacturing, gyms, or retail spaces

- Mounting height is 15-30 feet, where a wide distribution pattern provides uniform coverage

- Dry indoor locations like distribution centers, aircraft hangars, or convention centers

- Need motion sensor integration for 70-80% additional energy savings in intermittently occupied spaces

- Wire or chain mounting is available and can support 15-20 pounds more than the existing fluorescent weight

Do not Use LED Linear High Bays When

- Mounting height exceeds 30 feet, where wide distribution becomes ineffective, and UFO high bays work better

- Wet or washdown environments that require IP65+ ratings for food processing or outdoor applications

- Replacing metal halide systems with UFO high bays provides better beam control and impact resistance

- High-impact environments needing IK08+ ratings that linear fixtures do not provide

- 480V systems without confirming driver compatibility as standard fixtures cause immediate failure on high voltage

What We Verify Before You Order

We confirm

- Existing fluorescent tube count and fixture layout

- Mounting height and installation method (wire, chain, pendant)

- Electrical voltage (100-277V standard or 277-480V industrial)

- Environmental conditions (dry location vs washdown requirements)

- Control needs (dimming, motion sensors, emergency backup)

If we provide a lighting plan, you will get

- Exact fixture placement showing uniform coverage patterns

- Verified lumen levels meeting workspace requirements

- Energy savings calculations with payback period projections

Note: Guidance is general planning information. Final selection should be validated with a photometric plan and confirmed by a licensed professional when required for code- or safety-critical areas.

What are LED Linear High Bays?

Linear high bay lights are panel-style indoor LED High Bay Lights that replace F54/T5/HO or T8 fluorescent systems in high ceiling applications. These rectangular fixtures use LED strips on the back panel to deliver uniform light distribution throughout large spaces. They are a common form of LED warehouse lights used in commercial warehouses today.

Wire or chain mounting provides secure installation, though pendant and surface mount options are available for specific layouts. Wide light distribution creates even coverage without hot spots or dark areas.

We offer these fixtures in 100-277V standard voltage and 277-480V high voltage configurations, plus color-adjustable and wattage-adjustable models for flexibility.

The customer had fluorescent high bays and got tired of the poor light quality. We converted the fixtures over one-for-one to LED Linear High Bays and made the lighting brighter and more balanced.

LED Linear High Bay Benefits vs Fluorescent Fixtures

Linear high bay LED lights offer key advantages over fluorescent systems in energy use, maintenance, and performance:

- Significant energy savings: Expect 50% or greater energy cost reduction compared to fluorescent linear lighting. Motion sensors can boost savings to 70-80% in intermittently occupied spaces.

- Superior light quality: High CRI 70+ LED technology maintains consistent brightness and color rendering throughout its 50,000+ hour lifespan.

- Eliminated maintenance: No bulb replacements, no ballast failures, and no flickering end-of-life issues found in fluorescent systems.

- Silent operation: LED drivers operate silently, unlike fluorescent ballasts that can hum over time.

- Instant illumination: Full brightness immediately upon startup, even in cold environments where fluorescents struggle.

- Motion sensor compatibility: Rapid on/off cycling and smooth dimming work with occupancy controls without special ballasts.

- Standard dimming capability: Most models include 0-10V dimming to save energy during low-activity periods.

- No hazardous materials: LEDs contain no mercury, eliminating the need for special disposal and environmental concerns.

- Easy installation: Direct wire connection with line, neutral, and ground, with no ballast wiring complexity.

* The U.S. Department of Energy's commercial lighting studies demonstrate that LED technology consistently outperforms fluorescent systems in industrial applications. According to DOE's LED lighting guidance, LED fixtures can reduce energy consumption by 50% or more when replacing traditional fluorescent high bay systems in warehouse and manufacturing environments.

What are the Cost Savings and ROI When You Convert from Metal Halide to LED?

165W LED Linear High Bay vs 400W Metal Halide Replacement (with ballast)

Assumptions: Based on 24 hours/day, 200 days/year at $0.20/kWh,

50 fixture(s), and a 15% ballast factor applied to the metal halide wattage

(400W lamp + 15% ballast = ~ 460W input).

•

Energy cost and ROI calculations are based on energy savings only and assume an LED fixture cost of

$155.00 per fixture.

• Maintenance savings from reduced bulb and ballast replacements are not included

in these calculations.

| Metal Halide (460W per fixture) |

Annual Energy Cost (per fixture): $441.60 Annual Energy Cost (all 50 fixtures): $22,080.00 5 Year Energy Cost (all fixtures): $110,400.00 5 Year Savings (all fixtures): $0.00 |

| LED Linear High Bay (165W per fixture) |

Annual Energy Cost (per fixture): $158.40 Annual Energy Cost (all 50 fixtures): $7,920.00 5 Year Energy Cost (all fixtures): $39,600.00 5 Year Savings (all fixtures): $70,800.00 |

| Savings & Payback |

Single Fixture Annual Savings (energy only): $283.20 50 Fixture Annual Savings (energy only): $14,160.00 LED Fixture Project Cost (50 fixtures): $7,750.00 Simple Payback from Energy Savings Only: under 7 months |

| Performance Summary |

Energy Reduction: 64% 5-Year ROI (All Fixtures, Energy Only): 814% Lamp Life: 50,000+ (LED) vs 15,000 (MH) |

In this example with 50 fixture(s), total LED fixture investment is approximately $7,750.00, and estimated annual energy-only savings are $14,160.00. Simple payback based on energy savings alone is under 7 months. Maintenance savings from eliminating metal halide bulb and ballast replacements provide additional value throughout the fixture's 50,000-hour lifespan, but are not included in this ROI calculation.

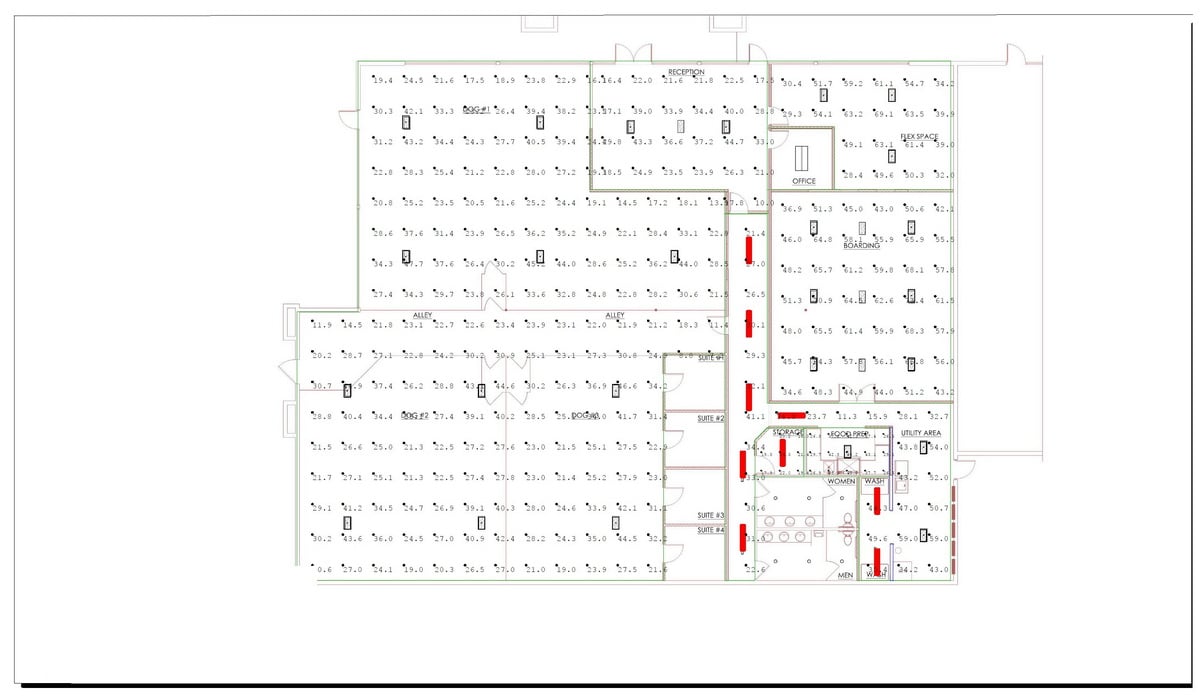

Case Study: Doggy Day Care with LED Lighting Supply 80 / 90 / 105 Watt Adjustable Linear LED High Bay in Scottsdale, AZ

|

After: 80 / 90 / 105 Watt Adjustable Linear LED High Bay | 12000 to 15750 Lumens |

After: 80 / 90 / 105 Watt Adjustable Linear LED High Bay | 12000 to 15750 Lumens |

|

|

Lighting Plan We Created for the Customer

|

Lighting Plan |

|

Doggy Day Care Installation Plan Metrics

- Mounting height: 14 ft

- Fixture Used: LLS-X-HBLIN8-2-105/90/80-CC: 80 / 90 / 105 Watt Adjustable Linear LED High Bay | 12000 to 15750 Lumens | 4000K / 5000K Adjustable | 100-277V | 2 Foot

- FC achieved: 55.57 fc average

- Uniformity (Avg/Min): 1.61

Best Applications for LED Linear High Bays

- Manufacturing Plants: Provide wide-area coverage using wire or chain mounting. Broad distribution eliminates shadows around machinery and work areas.

- Distribution Centers: Deliver uniform illumination across aisles, racking, and sorting zones. 277-480V models integrate with industrial electrical systems.

- Aircraft Hangars: LED aircraft hangar lights are designed for large, open spaces with high ceilings. Rectangular panel optics maintain consistent brightness across maintenance and inspection bays.

- Food Processing Facilities: Silent, mercury-free operation supports sanitary environments. LED NSF food grade lights meet food safety and washdown compliance standards, depending on the model.

- School Gyms: Instant-on performance supports sports and events. LED gymnasium lights with motion sensor integration offer 70-80% additional energy savings during low-use periods.

- Convention Centers: Provide uniform, large-area coverage with adjustable color temperatures (3000K/4000K/5000K) for trade shows, ceremonies, and multi-purpose events.

- Fitness Centers: Flicker-free illumination enhances comfort during high-motion activities. Emergency backup options ensure safety lighting during outages.

- Big Box Retail Stores: Deliver bright, uniform product visibility without hot spots. Built-in dimming reduces energy usage during low-traffic hours.

Proper workplace illumination requirements for industrial facilities are outlined by OSHA's occupational safety standards. OSHA's workplace lighting guidance emphasizes the importance of adequate lighting levels in manufacturing and warehouse environments to prevent accidents and maintain worker safety.

The customer built a large indoor riding arena and used our LED Linear High Bays inside to provide bright, balanced lighting.

LED Replacement Guide for Fluorescent Systems

Replacing F54/T5/HO fluorescent fixtures with LED high bay lights follows straightforward one-for-one replacement ratios. The LED lumens needed depend on mounting height and specific application requirements (model dependent).

We typically recommend these replacement levels:

- 4 tube F54/T5/HO: 12,000 to 18,000 LED lumens

- 6 tube F54/T5/HO: 18,000 to 24,000 LED lumens

- 8 tube F54/T5/HO: 24,000 to 40,000 LED lumens

Installation mirrors existing fluorescent mounting - pendant, chain, or wire cable suspension connects to the same mounting options. Three-wire connection (line, neutral, ground) eliminates ballast complexity and reduces installation time.

Interior space converted over to LED using our Linear High Bays

Large indoor truck maintenance bay converted to our LED Linear High Bays

LED Linear vs UFO High Bay Comparison

Shared Capabilities

- Excellent performance. We offer linear LED warehouse lights, LED gymnasium lights, workshops, and LED aircraft hangar lights

- Wattage-adjustable and color-adjustable configurations available

- Emergency backup and motion sensor options

- 100-277V standard and 277-480V high voltage models

- Energy-efficient, maintenance-free operation

- DLC qualified for utility rebates, UL/ETL safety listed per listed certifications

- 5-year warranty with USA-based support

Key Differences

- UFO fixtures suit metal halide replacements; linear fixtures replace fluorescent systems

- UFO models carry IP65+ wet location ratings; linear fixtures are dry location only

- UFO fixtures feature IK08+ impact resistance for enhanced durability; linear models lack impact ratings

- UFO fixtures offer narrow beam optics for mounting heights above 30 feet; linear fixtures maintain a wide distribution only

Expert Consultation for LED Linear High Bay Selection

Choosing the right linear high bay configuration requires balancing mounting height, space layout, occupancy patterns, and energy goals. Our sales engineers bring 15+ years of commercial lighting experience to every project consultation.

We analyze your requirements and recommend the most cost-effective solution for your application. Our complimentary lighting design service includes photometric analysis to ensure proper illumination levels and uniform distribution throughout your space when properly specified. This eliminates guesswork and supports optimal performance from your LED investment.

110 / 165 / 220 Watt Adjustable Linear LED High Bay | 15400 to 30800 Lumens was the perfect fixture for this customer's large outdoor storage building.

Safety and Performance Certifications

All our fixtures carry essential certifications, including DLC Premium for energy efficiency and rebate eligibility, UL Listed and ETL Listed for electrical safety and performance, per listed certifications. These certifications help ensure safety, performance, and energy efficiency, and may qualify your project for utility rebates and tax incentives.

Safety testing and energy efficiency validation for LED lighting fixtures are performed by independent testing organizations. The UL 2108 standard for LED equipment ensures electrical safety and performance reliability, while the Design Lights Consortium (DLC) qualification program verifies energy efficiency performance and establishes utility rebate eligibility for commercial LED fixtures.

Warranty and Support

All our lights come with at least a 5-year warranty, and all warranty support is based in the USA. Our experienced support team understands the importance of keeping your lighting operational and will work quickly to resolve any warranty issues.

Maximize Your Investment with Professional Energy Analysis

Our lighting specialists provide precise energy savings calculations comparing your existing fluorescent system to LED warehouse lighting. These projections factor in utility rates, operating hours, and control strategies to predict payback periods with lower energy consumption, subject to site conditions.

We also create professional lighting plans showing fixture placement and coverage patterns to optimize performance. This complimentary analysis helps ensure your LED investment delivers maximum ROI while meeting all performance requirements for your specific application.

Common Mistakes and How to Avoid Them

After thousands of fluorescent-to-LED conversions, the same installation errors keep showing up on job sites. Most stem from treating linear high bays like other fixture types instead of understanding their specific limitations and requirements.

- Installing linear high bays above 30 feet, where their wide distribution pattern becomes ineffective. Use UFO high bays with narrow beam optics for mounting heights over 30 feet.

- Specifying dry-location fixtures for food processing or wash-down areas. Linear high bays lack IP ratings and fail quickly in wet environments that require IP65 or higher protection.

- Sizing replacements based on fluorescent tube count instead of actual lumen requirements. See the replacement guide section above for proper lumen recommendations by tube count.

- Wiring motion sensor fixtures without connecting the dimming leads properly. The sensors control the dimming function, not just on/off switching like standard occupancy sensors.

- Using standard 120-277V fixtures on 480V industrial systems without checking driver compatibility. This creates immediate failure and potential safety hazards during startup.

- Mounting fixtures to the existing chain or cable without verifying the weight capacity. LED linear high bays often weigh 15-20 pounds more than the fluorescent fixtures they replace.

- Installing emergency backup fixtures without confirming they meet local fire marshal requirements. Some jurisdictions require specific lumen levels or battery backup durations that vary by application.

LED Linear High Bays Frequently Asked Questions

What are LED linear high bays used for?

LED linear high bays replace F54/T5/HO fluorescent systems in warehouses, manufacturing plants, gyms, and retail spaces with 15-30 foot ceilings. Wide light distribution provides uniform coverage without hot spots or dark areas in dry indoor locations.

How do I choose the right lumen output for my space?

Match LED lumens to your existing fluorescent tube count: 4-tube systems need 12,000-18,000 lumens, 6-tube systems need 18,000-24,000 lumens, and 8-tube systems need 24,000-40,000 lumens. Verify final selection with a photometric plan since mounting height affects actual lumen requirements.

What voltage options are available?

100-277V standard voltage works for most commercial applications, while 277-480V high voltage models integrate with industrial electrical systems. Confirm driver compatibility before installation since standard fixtures cause immediate failure on 480V systems.

Can LED linear high bays be used in wet locations?

No. These fixtures are dry location only and lack the IP ratings required for food processing washdown or wet environments that need IP65+ protection.

What is the maximum mounting height for linear high bays?

Linear high bays work effectively at 15-30 feet mounting height. Above 30 feet, wide distribution becomes ineffective and UFO high bays with narrow beam optics provide better performance.

Do LED linear high bays work with motion sensors?

Yes. Motion sensor models can deliver 70-80% additional energy savings in intermittently occupied spaces. These sensors require dimming wire connections for proper operation - not just standard on/off wiring.

How much energy do LED linear high bays save compared to fluorescent?

Expect 50% or greater energy cost reduction compared to fluorescent systems. Motion sensors can boost total savings to 70-80% in spaces with intermittent occupancy.

What certifications do these fixtures have?

Fixtures carry DLC Premium, UL Listed, and ETL Listed certifications per listed specifications. These certifications qualify projects for utility rebates and tax incentives.

What warranty is included?

All fixtures include at least a 5-year warranty with USA-based support.

When should I choose UFO high bays instead of linear high bays?

Choose UFO high bays when replacing metal halide systems, when mounting height exceeds 30 feet, when IP65+ wet location ratings are required, or when high-impact environments need IK08+ ratings that linear fixtures do not provide.