Buyers Guide to LED Warehouse Lighting

Commercial and industrial warehouses across the nation are discovering substantial energy savings by upgrading to LED warehouse lighting systems. Over my 15+ years in commercial lighting, I’ve witnessed firsthand how these fixtures transform operations through dramatically reduced energy consumption, minimal maintenance requirements, exceptional light output, and uniform illumination patterns. Warehouses can slash overhead costs by transitioning from traditional lighting solutions to energy-efficient high bay LED systems.

The U.S. Department of Energy’s solid-state lighting program demonstrates that LED technology can deliver energy savings of 75% or more compared to traditional high-intensity discharge lighting commonly used in warehouse applications. These efficiency gains translate directly into reduced operating costs and lower carbon footprints for industrial facilities nationwide.

Beyond lower energy bills, these installations virtually eliminate maintenance expenses. LED high bay lights solutions deliver unmatched energy efficiency and extended lifespans, making tube replacements, bulb changes, and ballast failures obsolete. These LED commercial lights replace metal halide, fluorescent, halogen, and incandescent fixtures throughout warehouse environments. Large warehouse spaces with high ceilings present unique lighting challenges where most conventional fixtures lack sufficient power to deliver adequate ground-level illumination.

Warehouse Lighting Selection Checklist

- Target foot-candles by task (picking, aisles, docks, etc.)

- Mounting height and spacing constraints

- Fixture type: UFO vs Linear (and where each wins)

- Beam angle/optics for open areas vs racking aisles

- Controls: 0-10V dimming + occupancy/daylight harvesting

- Environment: IP rating for moisture/washdown, temperature limits

- Impact risk: IK rating for ball strikes, lifts, and equipment contact

- Certifications & warranty: DLC/UL/ETL + support terms

Warehouse Lighting Buyer’s Guide: How to Choose the Right System

This buyer’s guide walks warehouse managers, facility engineers, and contractors through the key decisions required to select the right LED warehouse lighting system – from light levels and fixture types to controls, safety ratings, and long-term energy savings.

Starting with a Professional Lighting Plan

Complimentary Warehouse Lighting Design Services

Creating a comprehensive lighting plan should be your priority before purchasing any LED fixtures. Different warehouse spaces demand specific lighting solutions based on operations, ceiling heights, and work requirements. Light levels vary significantly depending on warehouse functions and purposes. No two facilities share identical requirements, making proper planning absolutely critical. Poor planning becomes immediately apparent when fixtures activate. Overlighting, insufficient illumination, or unbalanced coverage creates obvious operational problems. A professionally designed warehouse lighting plan serves as the foundation for all subsequent decisions, ensuring optimal fixture selection without unnecessary purchases.

Professional lighting designers often reference the Illuminating Engineering Society (IES) recommended practices when developing warehouse lighting plans. These industry standards provide detailed guidance on illumination levels, uniformity ratios, and fixture spacing requirements specific to various warehouse operations and storage configurations.

Case Study: Conversion of (72) T5 6 tube fixtures to LED Lighting Supply 200 Watt LED UFO Fixtures (one-for-one replacement) in Williston, ND

|

Before: T5 54W HO Fluorescent Fixtures |

After: 200 W LED UFO Fixtures |

|

|

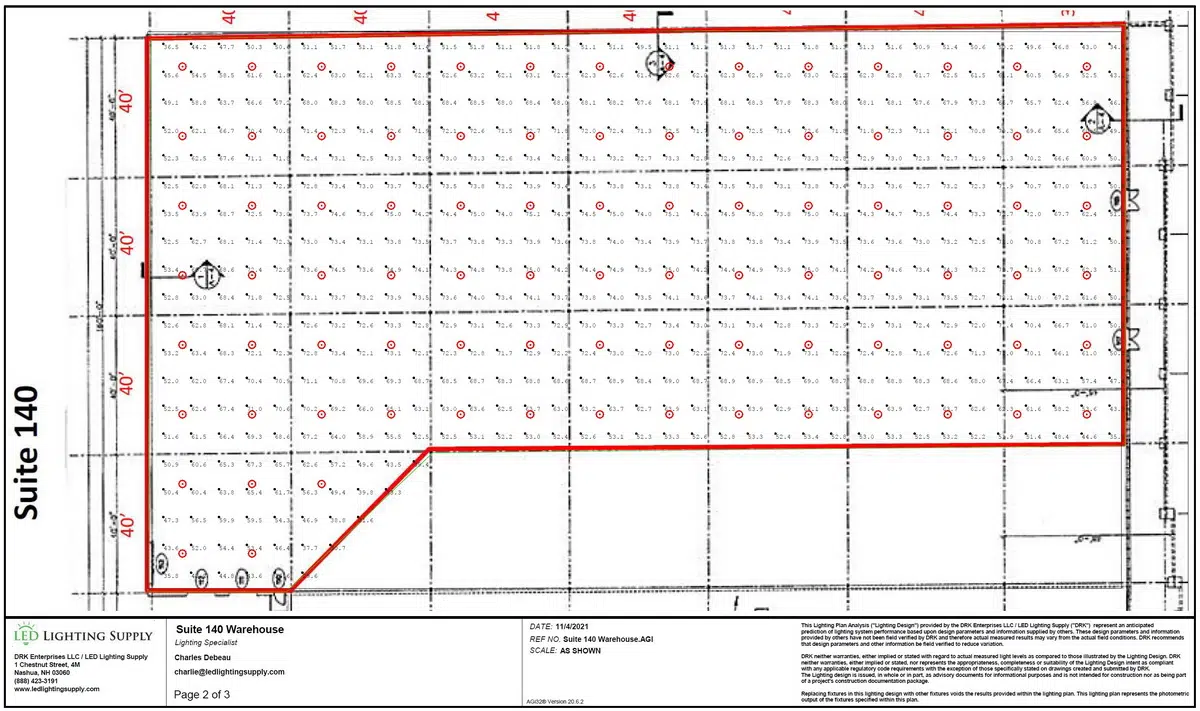

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

LED High Bays Warehouse Installation Lighting Plan Metrics

- Mounting height: 20 ft

- Fixture Used: MLLG-LED-HBC-200-5-120: 100 / 120 / 150 / 200 Watt Adjustable LED UFO High Bay | 15000 to 30000 Lumens | 5000K | 100-277V | White Housing

- FC achieved: 60.33 FC average

- Uniformity (Avg/Min): 1.42

Case Study LED High Bays Warehouse Installation Energy Savings: 200W LED vs 324W Fluorescent Replacement (with ballast)

Assumptions: Based on 18 hours/day, 300 days/year at $0.08/kWh

| Fluorescent (373W) | Annual Energy Cost: $160.96 5 Year Energy Cost: $804.82 5 Year Savings: $0.00 |

| LED UFO Fixture (200W) | Annual Energy Cost: $86.40 5 Year Energy Cost: $432.00 5 Year Savings: $26,842.75 |

| Savings & Payback | Single Fixture Annual Savings: $74.56 72 Fixture Annual Savings: $5369 ROI Timeline: Under 19 months |

| Performance Summary | Energy Reduction: 46% 5-Year ROI: 22,648% Lamp Life: 50,000+ (LED) vs 30,000 (fluorescent) |

Calculating Fixture Requirements

Most existing warehouses work perfectly with our high bay fixtures using current mounting locations. We typically recommend maintaining existing layouts when fixtures are properly spaced. New construction projects benefit from custom lighting plans that demonstrate illumination levels, uniformity, fixture quantities, and optimal placement positions. Our design team creates detailed lighting plans tailored to your specific facility requirements.

Eliminating Purchase Uncertainty

We’ve completed thousands of complimentary warehouse lighting plans using hundreds of available LED fixtures to meet diverse requirements and budgets. Our warehouse maintains extensive inventory ready for immediate shipment. This streamlined approach enables rapid progression from lighting plan completion to fixture delivery and installation.

Establishing Required Light Levels

Understanding necessary illumination levels represents the most critical decision factor. Never begin fixture selection by assuming you need specific wattage requirements. Focusing on required light output rather than wattage ensures optimal results. Professional lighting plans identify ideal fixtures based on illumination requirements, mounting heights, and spacing considerations.

This eliminates guesswork and prevents costly mistakes from presumed fixture selections. Mounting height directly correlates with lumen requirements. Higher installations demand increased light output to maintain adequate ground-level illumination.

Here are our standard recommendations based on installation height:

- Fixtures mounted 10-15 feet high require 10,000-15,000 lumens

- Fixtures mounted 15-20 feet high require 16,000-25,000 lumens

- Fixtures mounted 25-35 feet high require 36,000 lumens or more

Recommended Foot-Candle Levels for Warehouse Areas

| Task / Area | Recommended Foot Candles |

|---|---|

| Warehousing – Inactive Area | 5-10 fc |

| Warehousing – Active – Large Items | 10-20 fc |

| Warehousing – Active – Small Items | 15-60 fc |

| Warehousing – Active – Medium Items | 20 fc |

| Warehousing – Active – Fine Items | 20-50 fc |

| Shipping and Receiving Area | 30 fc |

| Receiving and Shipping Dock | 5-20 fc |

| Receiving and Staging | 15-60 fc |

| Maintenance and Shop Areas | 50 fc |

| Cold Storage | 10-30 fc |

| Open Warehouse | 10-30 fc |

| Warehouse with Aisles | 10-30 fc |

The U.S. Department of Energy’s commercial building guidelines emphasize that proper warehouse lighting can reduce energy consumption by up to 50% when upgrading from high pressure sodium or metal halide systems to LED technology, while maintaining the recommended foot-candle levels for safe operations.

To explore available fixture options after reviewing this guide, visit our full selection of LED warehouse lighting designed for industrial and commercial facilities.

Selecting the Optimal LED Warehouse Fixture Type

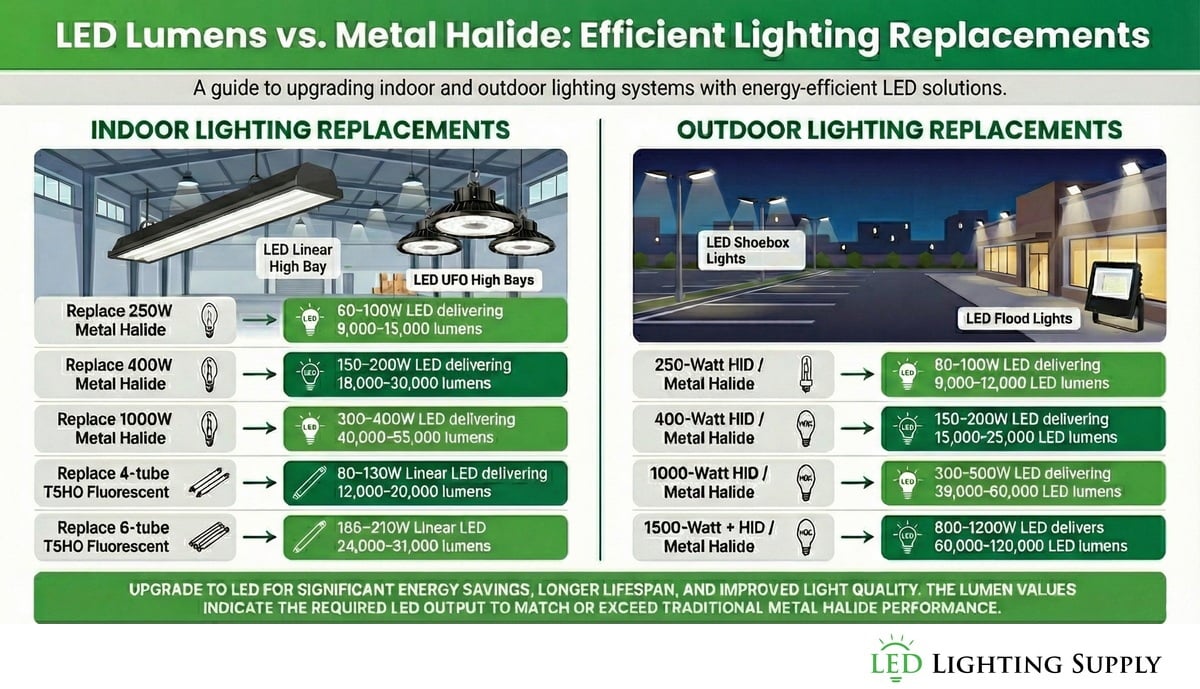

Warehouse applications utilize two primary fixture categories: Linear LED high bay lights (panel-style fixtures), and UFO LED high bay lights (compact, round, rugged designs). Linear panel high bays excel as fluorescent replacements for T8 and T5 HO systems.

Facilities upgrading from tube-style fixtures find that these panels provide seamless transitions with familiar form factors. UFO high bays dominate high-ceiling applications through rugged construction and superior durability compared to linear alternatives. Most UFO fixtures carry IP65 wet location ratings. Optional optics enable beam narrowing for extremely high ceiling installations.

UFO Round Fixtures – Superior Metal Halide Replacement

UFO fixtures deliver exceptional durability through compact, robust construction. These fixtures provide outstanding replacements for metal halide and high-pressure sodium systems. We typically recommend UFO fixtures for warehouses and gyms requiring dependable performance. Their IP65+ ratings handle damp conditions effectively.

- Available Wattages: 100-600 Watts

- Light Output: 13,000-96,000 lumens

- Efficiency: 130-180 lumens per watt

- Replaces: 250-2000 Watt Metal Halides

- Color Temperatures: 4000K or 5000K optimal

- Color Quality: 70+ CRI

- Weather Protection: IP65 rated

- Voltage Compatibility: 100V-277V standard, 277V-480V high voltage

- Impact Resistance: IK08 or higher

- Installation Options: Eye hook, pendant mounting

- Available Features: Surge protection, motion sensors

For commercial LED products used in warehouse applications, the Design Lights Consortium (DLC) maintains energy efficiency standards that help facility managers identify qualified high-performance fixtures. Additionally, UL’s lighting safety standards ensure that LED fixtures meet rigorous safety testing requirements for industrial installations.

Linear Panel Fixtures – Ideal Fluorescent Replacement

Linear fixtures work exceptionally well in gyms and warehouses while providing direct replacements for T5 and T8-style high bay systems. Panel-style fixtures require dry environments without potential impact concerns since most models lack impact or wet location ratings.

- Available Wattages: 80-500 Watts

- Light Output: 11,000-42,000 lumens

- Efficiency: 135-140 lumens per watt

- Replaces: 4-8 tube T5 54-Watt HO systems

- Color Temperatures: 4000K or 5000K optimal

- Color Quality: 70+ CRI

- Weather Protection: Select models only

- Voltage Compatibility: 100V-277V standard, 277V-480V select models

- Installation Options: Pendant, cable mount, ceiling mount

- Available Features: Surge protection, motion sensors

Maximizing Energy Savings Through LED Efficiency

Efficacy measures how effectively LEDs convert electricity into visible light. This metric appears as lumens per watt on specification sheets, representing the energy consumption required for specific light output. Higher efficacy means lower energy consumption for equivalent illumination. You can calculate efficacy by dividing lumens by watts when not listed. Higher efficacy LEDs cost slightly more initially but consume significantly less energy throughout their operational lifetime.

Lower efficacy fixtures may seem attractive due to reduced upfront costs, but they generate substantially higher energy bills over time. The energy savings from high-efficacy fixtures far exceed any initial price differences.

Consider this comparison:

- A 300-Watt LED at 150 lumens/watt produces 45,000 lumens

- A 500-Watt LED at 90 lumens/watt also produces 45,000 lumens

- The efficient 300-Watt fixture saves 200 watts per operating hour

Investment Returns from Efficient Warehouse Lighting

High-efficiency warehouse fixtures require slightly higher initial investment but deliver substantial energy bill reductions that quickly offset purchase price differences. Over the fixture’s operational lifetime, efficiency gains provide significant cost savings. Premium efficient high bay fixtures save considerable money through reduced energy consumption, easily justifying their slightly higher purchase costs through operational savings.

Understanding Voltage Requirements

Commercial and industrial voltage typically ranges between 100 and 480 volts. LED fixtures accommodate these ranges through two primary driver options. Drivers automatically adjust to incoming voltage without requiring installation of voltage settings.

Standard LED driver voltage ranges include:

- 100V-277V (Standard driver included with fixture)

- 277V-480V (High voltage option available)

LED drivers feature auto-switching capabilities that adjust automatically to available voltage within the driver’s specified range. No voltage adjustments are needed during installation when the building voltage falls within the driver’s operating parameters.

Optimal Color Temperature Selection for Warehouse Applications

Color temperature uses the Kelvin scale, where lower numbers represent warm yellow light while higher numbers indicate cool blue light.

- 4000K provides an excellent replacement for fluorescent systems and works well in commercial environments requiring comfortable working conditions.

- 5000K delivers outstanding performance for industrial applications and serves as the perfect replacement for metal halide and other HID systems.

Based on our experience, over 90% of the warehouse fixtures we supply use 5000K color temperature due to its superior performance in industrial environments.

Color Rendering Requirements for Warehouse Lighting

CRI represents the Color Rendering Index, measuring light quality produced by any light source. LED high bay lights for warehouse applications should feature CRI ratings of 70 or above.

Better light quality reduces the quantity of light required for adequate illumination. Most warehouse applications perform excellently with 70 CRI ratings, providing sufficient color accuracy for typical operations.

Implementing Light Controls and Motion Sensor Technology

Light controls enable automated light management and power control functionality. Motion sensors represent the most effective control option for warehouse lighting applications.

Motion sensors automatically turn lights off in unoccupied warehouse areas. While LEDs provide substantial energy savings compared to traditional lighting, motion sensors amplify these savings considerably while extending fixture lifespans. Unlike other lighting technologies, frequent LED on/off cycling doesn’t reduce operational life.

0-10V dimmable drivers must be installed in LED fixtures to enable motion sensor compatibility. These drivers allow motion sensors to create automated low-light levels rather than simple on/off operation.

Some drivers only dim to 10% output at 0 volts rather than a complete shutdown. Future-proof your investment by specifying fixtures with dimmable drivers, even if controls aren’t immediately planned.

Case Study: Installation of new LED Lighting for Stone Basyx in Charlotte, NC

|

After: 150 Watt High Output UFO High Bay | 24000 Lumens |

|

Lighting Plan We Created for the Customer

|

Lighting Plan |

Heat Map |

|

|

Warehouse / Retail Lighting Installation Plan Metrics

- Mounting height: 23 ft

- Fixture Used: MLLG-LED-HBHO-150-5-120: 80 / 100 / 120 / 150 Watt Adjustable UFO High Bay | 16000 to 30000 Lumens | 5000K | 100-277V | High Performance

- FC achieved: 65.36 FC average

- Uniformity (Avg/Min): 2.21

Impact Resistance for Warehouse Operations

Warehouse operations occasionally involve fixture impacts during normal material handling activities. This creates demand for rugged, impact-resistant lighting solutions in operational areas. IK ratings from IK01 to IK10 measure impact resistance capability, with IK10 representing maximum impact protection. UFO fixtures typically provide the best solution when impact resistance is required due to their robust construction and high impact ratings.

Wet Location Lighting Requirements

Fixtures installed in areas exposed to moisture require appropriate IP ratings for safe operation. An IP65 rating provides basic water protection for most wet location applications. Operations requiring high-pressure washdowns with hot water and steam need IP69K rated fixtures. UFO fixtures and LED NSF rated lights include IP ratings suitable for wet location installations. Most linear fixtures lack IP ratings, though some rated models are available.

When warehouse environments involve potential safety concerns or require specific safety lighting standards, OSHA’s safety requirements for workplace lighting provide detailed guidance on adequate illumination levels needed to maintain safe working conditions in industrial facilities.

Why Warehouse Lighting Experts Trust LED Lighting Supply

As a company specializing exclusively in LED technology, we’ve completed over 20,000 commercial lighting projects across diverse warehouse applications. Our team of lighting engineers provides precise energy savings calculations based on your existing fixtures and operating schedules, giving you exact projections for your upgrade investment. Unlike general electrical suppliers who carry multiple product lines, our exclusive focus on LED technology allows us to maintain deep technical expertise on every fixture we supply.

We stock only commercial-grade fixtures that meet rigorous industrial specifications, ensuring long-term performance in demanding warehouse environments. Our experienced product specialists work directly with facility managers to analyze specific lighting requirements, providing expert guidance that eliminates costly specification errors.