When to Use Vapor Proof Lights vs. Explosion Proof Lights (C1D1 / C1D2)

If you work in manufacturing, food processing, cold storage, wastewater, or chemical handling, you’ve probably heard people use the terms vapor proof, vapor tight, hazardous location, and explosion proof like they’re interchangeable. They are not.

Choosing the wrong fixture isn’t just a “performance” issue-it can become a code violation, a safety incident, or a serious ignition risk.

This guide explains when to use LED vapor-proof lights, when you legally need explosion-proof lights (C1D1/C1D2), and the real-world failure modes we see when fixtures are used outside their intended environment.

Important Rules (Read This First)

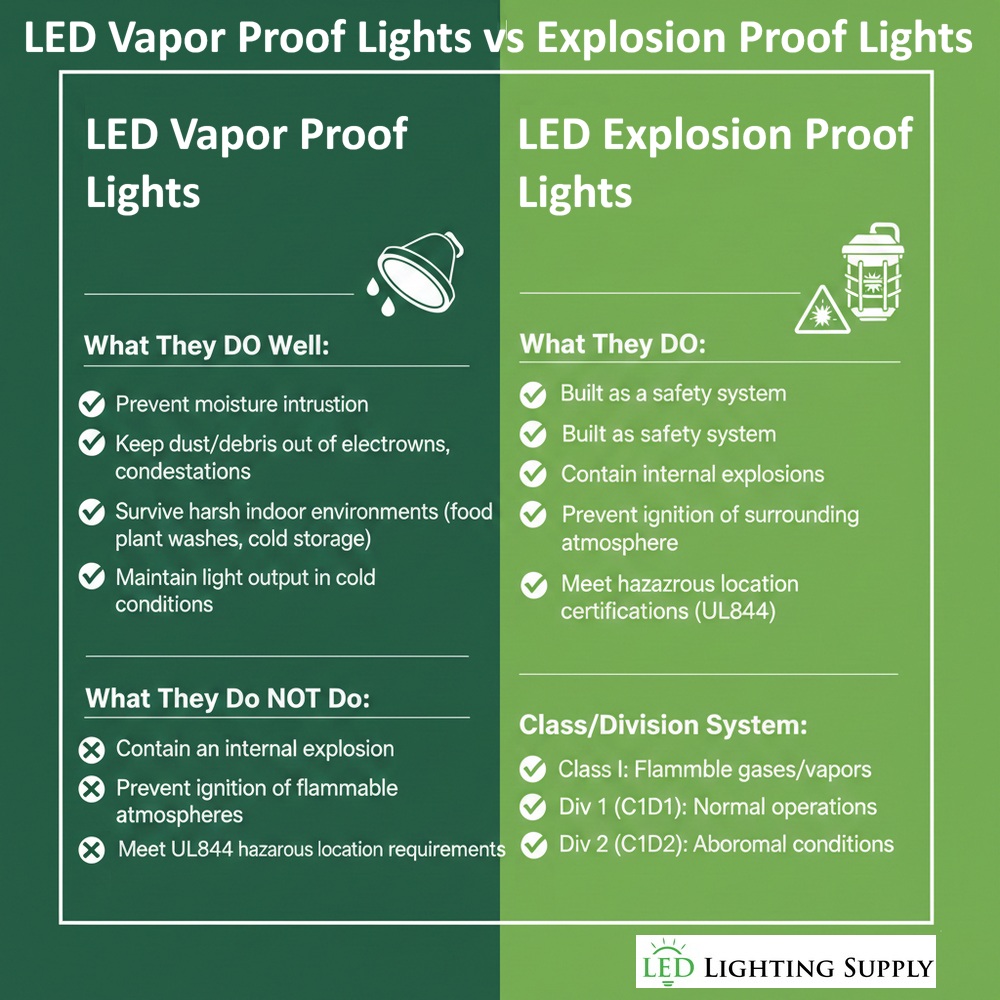

- Vapor proof / vapor tight fixtures are designed to keep out water, dust, humidity, and non-ignitable vapors (washdowns, damp locations, corrosion, and cold environments).

- Explosion-proof (hazardous location) fixtures are engineered to contain an internal ignition source, so they cannot ignite a surrounding flammable gas/vapor or combustible dust atmosphere.

- Never use vapor proof fixtures in a classified hazardous (explosive) atmosphere. Verify classification to confirm the required Class/Division/Group and select a properly listed hazardous location fixture.

The National Fire Protection Association (NFPA) 70, also known as the National Electrical Code (NEC), establishes the requirements for electrical equipment in hazardous locations. These classifications are determined by qualified professionals who evaluate the specific materials present, their concentrations, and operating conditions to ensure proper safety measures are implemented.

What “Vapor Proof” Really Means (And What It Does NOT Mean)

LED vapor proof (often called vapor tight) fixtures use sealed housings and gasket systems to protect drivers and LED boards from moisture, washdown spray, dust, and many corrosive environments. Many quality units target an IP65 wet-location level of protection (or better, depending on the fixture).

What vapor proof lights are built to do well:

- Prevent moisture intrusion from humidity, washdowns, and condensation

- Keep dust and debris out of electronics and optics

- Survive harsh indoor environments (food plants, car washes, cold storage, barns)

- Maintain light output in cold conditions where fluorescents struggle

What vapor proof lights are NOT built to do:

- Contain an internal explosion (they are not designed with flame paths and explosion containment)

- Prevent ignition of surrounding flammable atmospheres during a component failure

- Meet hazardous location listing requirements like UL844 for Class/Division areas

When You Should Use LED Vapor Proof Lights

Choose vapor proof fixtures when the problem is environmental exposure, not ignitable atmospheres. These are the applications where vapor tight lights are typically the right fit (and where you usually get the best ROI and service life).

Best Applications for Vapor Proof (Vapor Tight) Lighting

- Food processing & packaging areas: Frequent washdowns, steam, humidity, and sanitation chemicals (select fixtures and materials that match the cleaning process).

- Cold storage & freezers: Low temperatures, condensation cycles, door openings, and frost. LEDs provide instant-on and stable output in the cold.

- Car washes: Direct spray, soaps, constant humidity, and overspray demand sealed housings and durable lenses.

- Parking garages: Moisture, vehicle exhaust, and dust. Vapor tight fixtures hold up better and reduce maintenance visits.

- Warehouses with washdown zones: Maintenance areas, loading docks, or sanitation zones where water exposure is expected.

- Livestock barns & agricultural buildings: Dust, debris, moisture, and ammonia-like contaminants (material selection matters).

- Natatoriums / indoor pools: High humidity and chemical exposure that destroys standard fixtures quickly.

Explore options here: LED Vapor Proof Lights

Why You Must Never Use Vapor Proof Lights in Explosive Environments

Using a vapor proof light in an explosive atmosphere can create an ignition source. Even high-quality vapor-tight fixtures can fail electrically like any piece of equipment: a driver can arc, wiring can loosen, a component can overheat, or a seal can degrade.

In a normal industrial space, that’s a reliability problem. In a Class I hazardous space with flammable vapors, the same failure can become an ignition event.

Why: Vapor proof fixtures are not engineered with explosion-proof flame paths, threaded joints, and containment structures designed to cool escaping gases and prevent flame propagation. They are not certified/listed for hazardous locations.

The Occupational Safety and Health Administration (OSHA) provides comprehensive guidance on workplace safety in areas with potential fire and explosion hazards. OSHA’s electrical safety standards emphasize the critical importance of using properly rated equipment in hazardous locations to protect workers from ignition sources that could lead to fires or explosions.

That combination, non-rated equipment + ignitable atmosphere, is exactly what hazardous location codes are designed to prevent. If there is any chance your space is Class-rated, stop and classify before you buy fixtures. This is not an area where “close enough” is acceptable.

What “Explosion Proof” Means (C1D1 and C1D2)

Explosion proof (hazardous location) lighting is built as a safety system. The fixture is designed so that if ignition happens inside the housing, it is contained and cannot ignite the surrounding atmosphere. In North America, many hazardous location fixtures are selected using the Class/Division system:

- Class I = flammable gases or vapors

- Division 1 (C1D1) = ignitable concentrations can exist during normal operations

- Division 2 (C1D2) = ignitable concentrations are present only under abnormal conditions (leaks, failures)

See our explosion proof fixtures here: LED Explosion Proof Lights

When You Need C1D1 (Class 1 Division 1) Explosion Proof Lighting

Use C1D1 fixtures when flammable gases or vapors can be present during normal operation, not just “once in a while,” but as part of regular processes.

Best Applications for C1D1 Lighting

- Paint spray booths and finishing rooms: Solvent vapors can be present during standard operations.

- Certain chemical processing zones: Where flammable vapors are released or vented during normal production.

- Fuel handling areas: Transfer points, pump rooms, or enclosed zones where vapors can accumulate.

- Distillation areas: Processes involving flammable vapor release in routine production (site-specific classification required).

- Inside certain enclosures / rooms: Where ventilation limitations allow vapor accumulation during normal operations.

When You Need C1D2 (Class 1 Division 2) Explosion Proof Lighting

Use C1D2 fixtures when flammable gases or vapors are not expected during normal operations, but could exist under abnormal conditions, like a leak, a broken seal, or a ventilation failure.

Best Applications for C1D2 Lighting

- Perimeters around fuel storage and transfer equipment: Where vapors are typically controlled, but possible during failures.

- Wastewater treatment facilities: Methane or hydrogen sulfide risks often appear in specific zones and conditions.

- Refinery support areas: Adjacent spaces where flammable vapors are not normally present but could be during upsets.

- Chemical storage rooms with controls: Where normal operations are sealed, but leaks are possible.

- Process-adjacent manufacturing zones: Where vapors are usually contained, but the hazard exists if something goes wrong.

Critical Guidance: The Two-Way Mistake People Don’t Talk About

1) Vapor Proof Fixtures in Explosive Areas (Dangerous)

This point is worth repeating:

- IP ratings do not equal hazardous location ratings.

- Vapor proof fixtures are not built to contain ignition.

- Installing them in Class I areas can create an ignition source and a code violation.

2) Explosion Proof Fixtures in Vapor Proof / Washdown Environments (Often a Reliability Problem)

Explosion proof lights can be the wrong choice in a wet, corrosive, or washdown-heavy environment if the fixture is not built for that exposure.

Here’s why explosion proof fixtures can be damaged in “vapor proof” environments:

- Corrosion attacks flame paths and joints: Explosion proof housings rely on precision mating surfaces (often threaded) that must remain intact. Corrosive cleaners, salt air, chlorine atmospheres, and frequent chemical washdowns can degrade these surfaces over time.

- Washdowns can overwhelm designs that weren’t intended for high-pressure water: Not every explosion proof fixture is built for aggressive washdown procedures. If the lens, seals, or cable/conduit interfaces aren’t designed for that specific water exposure, you can end up with moisture intrusion, driver failure, or repeated maintenance events.

- Maintenance risk goes up in wet/dirty areas: Explosion proof fixtures are heavier and more complex to service. Opening housings in damp or dirty conditions can introduce contamination, and improper reassembly (gasket alignment, torque, cover seating) can create failures and downtime.

- Overkill doesn’t equal “better” in harsh environments: If the hazard is water/steam/cleaning chemicals-use a fixture engineered for that reality. A correctly specified vapor tight fixture often outlives a misapplied hazardous location fixture in wet/corrosive areas when properly selected.

A Simple Selection Checklist (What We Ask Customers)

- Is the area classified? (Class I/II, Division 1/2, Group A-G) If yes, start with the hazardous location rating and certification.

- Are flammable vapors present during normal operations? If yes, you’re likely in C1D1 territory (final classification must be verified by qualified professionals).

- Are flammable vapors only possible during abnormal conditions? If yes, C1D2 may apply (again, verify classification with qualified professionals and the Authority Having Jurisdiction (AHJ) where applicable).

- If the area is NOT classified: Is your main threat water, humidity, washdown, dust, cold, or mild corrosion? That’s where vapor proof fixtures are typically the right tool.

- What chemicals hit the fixture? Cleaner type, concentration, and frequency matter. Gaskets and lens materials must match the environment.

- How is it installed? Mounting height, spacing, wiring methods, and structural support impact reliability as much as fixture selection.

For safety testing and certification verification, both Underwriters Laboratories (UL) safety standards and DesignLights Consortium (DLC) energy efficiency standards provide useful guidance when you’re comparing fixtures.

UL standards address electrical safety and hazardous location compliance, while DLC standards help verify energy performance and efficiency (and can support rebate eligibility where applicable).

Common Mistakes We See (And How to Avoid Them)

- “It’s sealed, so it must be safe for fumes.” Sealed = ingress protection. Hazardous location = ignition containment + certification. These are different engineering problems.

- Installing vapor-proof fixtures because “the last ones worked.” Past performance doesn’t prove compliance. Facilities change processes, ventilation, chemicals, and storage. Re-verify classification with qualified professionals.

- Putting explosion-proof fixtures in aggressive washdown zones without checking construction details. Confirm the fixture is appropriate for washdown/chemical exposure and that installation methods won’t create ingress points over time.

- Treating C1D2 like a “lighter-duty” fixture. Division 2 is still a hazardous location. Wiring methods, components, and installation practices must be compliant.

Safety and Compliance Notes

Hazardous location lighting decisions affect worker safety and facility risk. Classification and installation should be performed by qualified professionals. For Class/Division areas, fixtures must match the certified rating for the location and be installed using compliant methods and rated components.

If you’re unsure whether a space is classified, or you suspect it might be, treat that uncertainty as a sign to verify before purchasing fixtures.

Warranty and Support

At LED Lighting Supply, our fixtures come with a minimum 5-year warranty, depending on model, with warranty support provided in the USA. If you ever need help with selection, layout planning, or documentation for your project, our team can walk through your application details so you end up with lighting that is safe, compliant, and built to last.

Need help? Talk to a product specialist: Contact us