ATEX Lighting Guide: Understanding Hazardous Location Zones vs Divisions

ATEX and IECEx classifications are frequently misunderstood by North American engineers, electricians, and facility managers. While the NEC Class / Division system is standard in the United States and Canada, most of the world relies on ATEX and IECEx Zone-based classifications to define hazardous (explosive) atmospheres.

This guide explains how ATEX Zones work, how they differ from NEC Divisions under UL 844, and how to interpret common ATEX and IECEx markings when selecting explosion-proof lighting for international or multinational projects. This content is intended for educational reference only and does not replace site-specific hazardous area classification.

Who This ATEX Guide Is For

- Electrical engineers working on EU or global industrial projects

- Facility managers responsible for hazardous location compliance

- OEMs and contractors sourcing explosion-proof lighting internationally

- North American teams translating NEC classifications into ATEX requirements

ATEX Lighting Guide (EU): How Zones Differ from Divisions

Outside North America, hazardous locations are commonly specified using ATEX (the European Union legal framework) and/or IECEx (an international certification scheme). These systems use a Zone-based classification that defines how frequently explosive atmospheres are present and what level of equipment protection is required.

UL provides a helpful overview of global hazardous location marking systems, including NEC, ATEX, and IECEx classifications: Global HazLoc and Explosive Atmosphere Markings (UL)

What Does ATEX Mean?

ATEX originates from the French term “ATmosphères EXplosibles”. It refers to two European Union directives governing equipment used in explosive atmospheres:

- Directive 2014/34/EU – equipment design and certification

- Directive 1999/92/EC – workplace safety requirements and zone classification

Lighting fixtures certified under ATEX are evaluated to ensure they will not ignite explosive gases, vapors, or dusts under both normal operation and defined fault conditions.

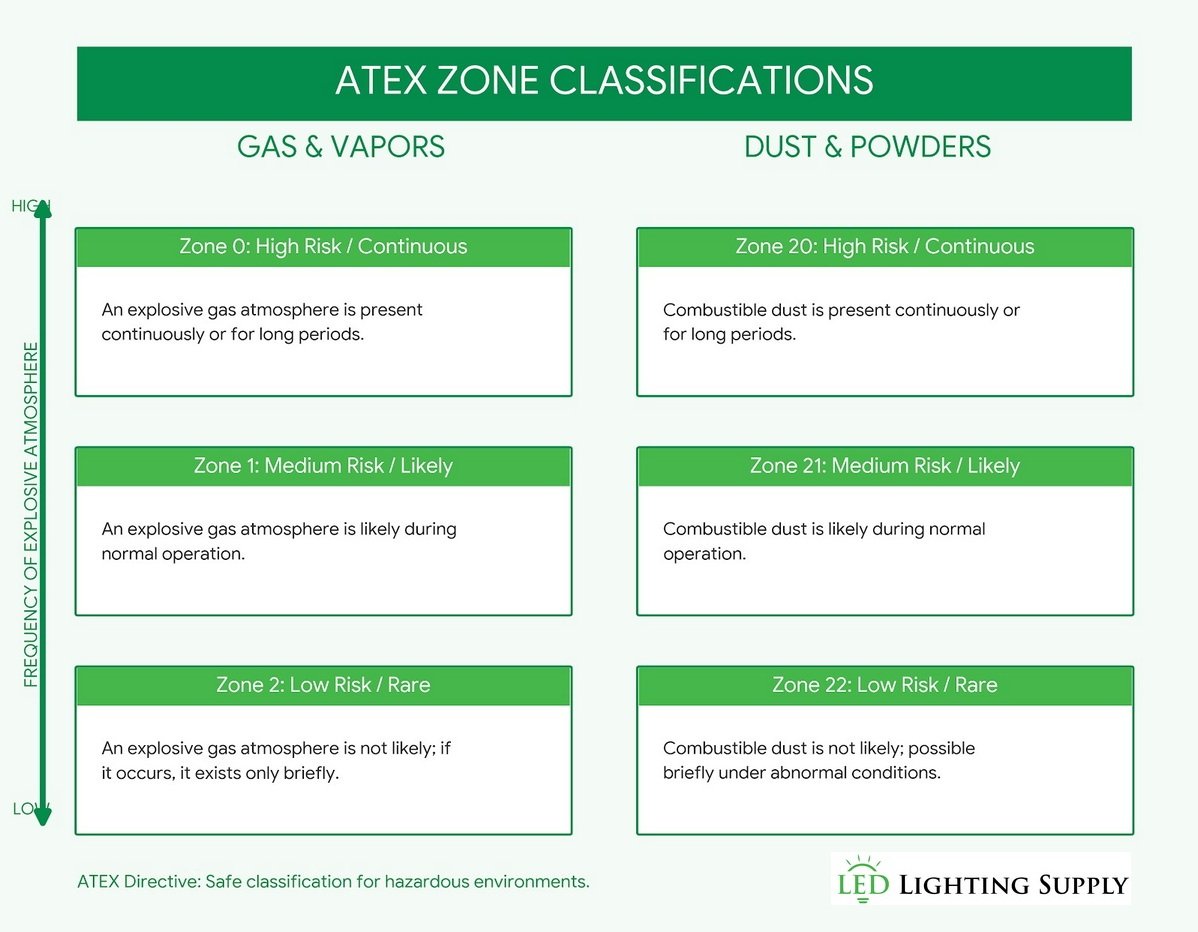

ATEX Gas Zone Classifications (Zones 0 / 1 / 2)

| Zone 0 | An explosive gas atmosphere is present continuously or for long periods |

| Zone 1 | An explosive gas atmosphere is likely during normal operation |

| Zone 2 | An explosive gas atmosphere is not likely during normal operation; if it occurs, it exists only briefly |

ATEX Dust Zone Classifications (Zones 20 / 21 / 22)

| Zone 20 | Combustible dust is present continuously or for long periods |

| Zone 21 | Combustible dust is likely during normal operation |

| Zone 22 | Combustible dust is not likely during normal operation; possible briefly under abnormal conditions |

UL 844 vs ATEX / IECEx: Practical “Rule of Thumb” Mapping

Key takeaway: These systems are related, but not interchangeable. The mapping below is intended only as a general reference to help interpret terminology. Final fixture selection must match the site’s documented hazardous area classification and applicable code requirements.

| Hazard Type | North America (NEC/CEC) | ATEX / IECEx (Zones) | Common Rule of Thumb |

|---|---|---|---|

| Gas / Vapor | Class I, Division 1 | Zone 0 / Zone 1 | Div 1 often aligns with Zone 1 and sometimes Zone 0, depending on continuous presence |

| Gas / Vapor | Class I, Division 2 | Zone 2 | Div 2 is commonly treated as roughly comparable to Zone 2 |

| Combustible Dust | Class II, Division 1 | Zone 20 / Zone 21 | Div 1 often aligns with Zone 21 and sometimes Zone 20 |

| Combustible Dust | Class II, Division 2 | Zone 22 | Div 2 is commonly treated as roughly comparable to Zone 22 |

ATEX Categories and IECEx Equipment Protection Levels (EPL)

In the Zone system, equipment may be identified using ATEX Categories (1 / 2 / 3 with G for gas or D for dust) and/or IECEx Equipment Protection Levels (EPL) such as Ga, Gb, Gc, Da, Db, or Dc. IECEx is widely accepted outside the EU and commonly used for multinational projects: IECEx Certification Overview (UL)

| Zone | ATEX Category | IECEx EPL | General Meaning |

|---|---|---|---|

| Zone 0 (Gas) | 1G | Ga | Very high protection; hazard present continuously |

| Zone 1 (Gas) | 2G | Gb | High protection; hazard likely during normal operation |

| Zone 2 (Gas) | 3G | Gc | Enhanced protection; hazard not likely in normal operation |

| Zone 20 (Dust) | 1D | Da | Very high protection; dust present continuously |

| Zone 21 (Dust) | 2D | Db | High protection; dust likely during normal operation |

| Zone 22 (Dust) | 3D | Dc | Enhanced protection; dust not likely in normal operation |

Ex Markings Explained: “Ex d”, “Ex e”, “Ex t”, and More

ATEX and IECEx markings include protection concepts such as Ex d (flameproof enclosure), Ex e (increased safety), and Ex t (protection by enclosure for dust). These indicate how equipment is designed to prevent ignition and what fault conditions it can withstand.

Bottom line: A fixture may be described as “explosion proof” in general language, but compliance depends on matching the correct Zone or Division, gas or dust group, temperature limits, and certification marking.

Common ATEX Classification Mistakes to Avoid

- Assuming Class I Division 1 automatically equals Zone 1

- Selecting ATEX equipment without confirming the Category or EPL

- Overlooking dust hazards in facilities focused on gas risks

- Using “explosion proof” as a generic term without verifying Ex markings

Important Safety & Compliance Notice

This guide is for general educational purposes only. ATEX and IECEx classifications must be performed by qualified professionals based on site-specific conditions, materials, ventilation, and applicable regulations.

Lighting manufacturers and suppliers do not assign ATEX Zones. Final fixture selection must comply with local laws, ATEX workplace directives, and the facility’s hazardous area classification dossier.

Need Help Matching ATEX Zones to the Right Fixture?

If you already have an ATEX Zone or IECEx EPL from your safety documentation and need help selecting compliant explosion-proof lighting, start here: LED Explosion Proof Lights